Time division multiplexing optical fiber grating sensing network with high renewability

A high reproducibility, fiber grating technology, applied in the field of sensing, can solve problems such as failure to work normally, limited number of gratings, and increased scanning cycle, etc., to achieve high reproducibility and reliability, high degree of automation, and convenient The effect of post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

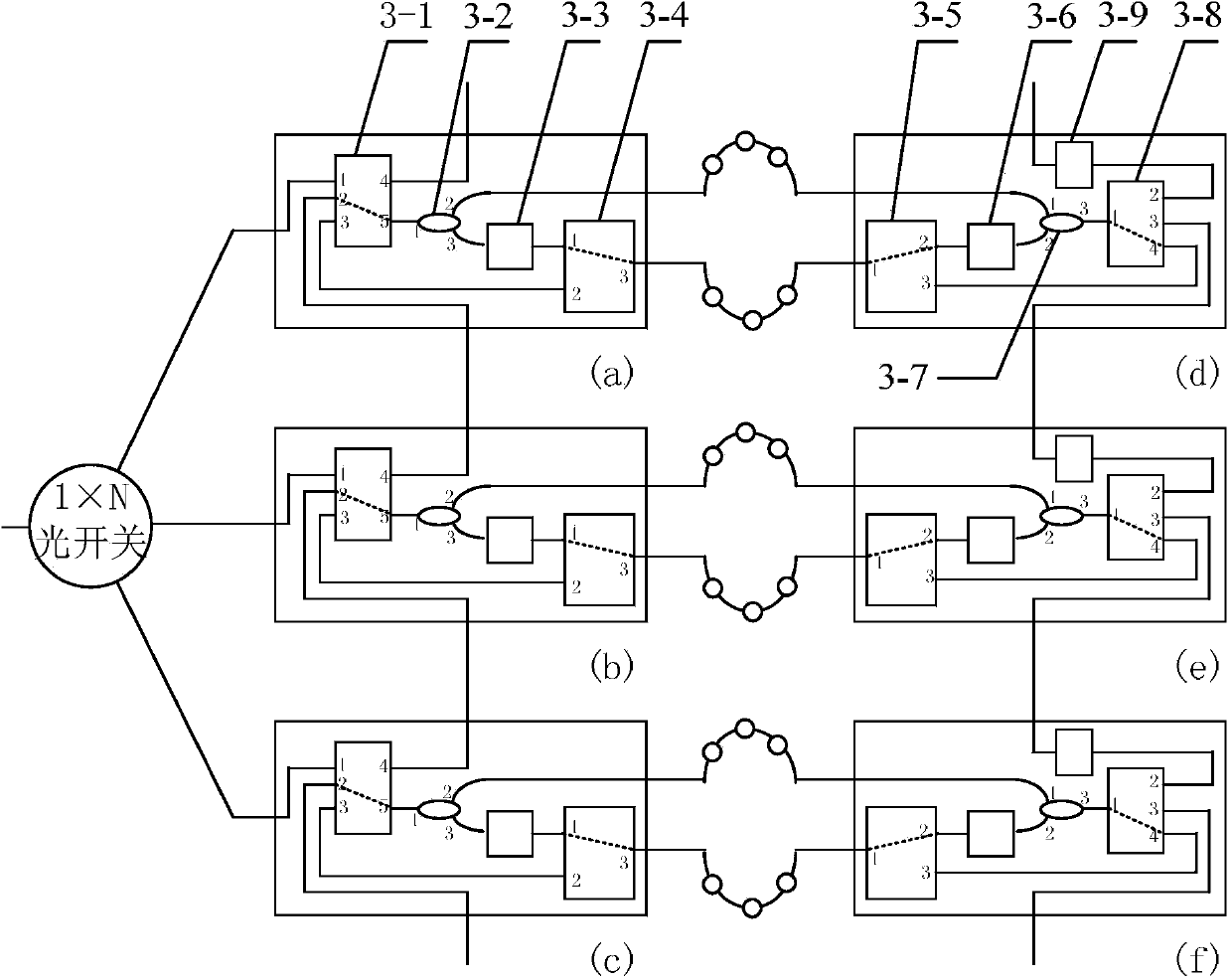

[0030] The technical solutions and implementation principles of the present invention will be further described below in conjunction with the accompanying drawings.

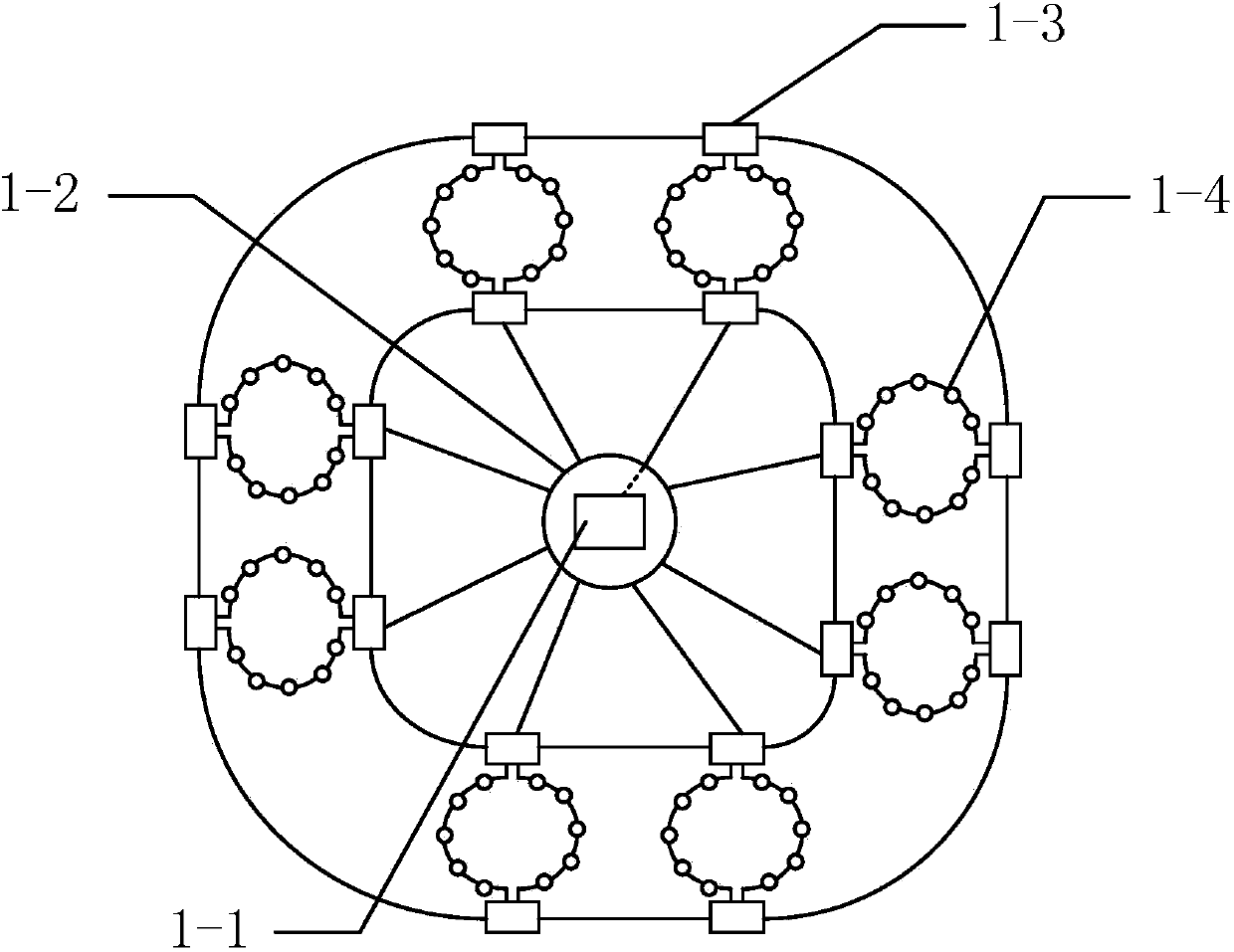

[0031] The present invention is a highly reproducible time-division multiplexing fiber grating sensor network, such as figure 1 As shown, it includes a control center 1-1, a 1×N optical switch 1-2 (that is, the main switch), N path selection and delay nodes 1-3 (that is, a remote node) and N weak reflection fiber grating transmission Sensing subnet 1-4 (that is, sensing subnet). The control center 1-1 is connected to N weak reflection fiber Bragg grating sensing subnets 1-4 through 1×N optical switches 1-2, and the weak reflection fiber Bragg grating sensing subnet 1-4 is selected by the path and the delay node 1-3 connected to form a ring structure.

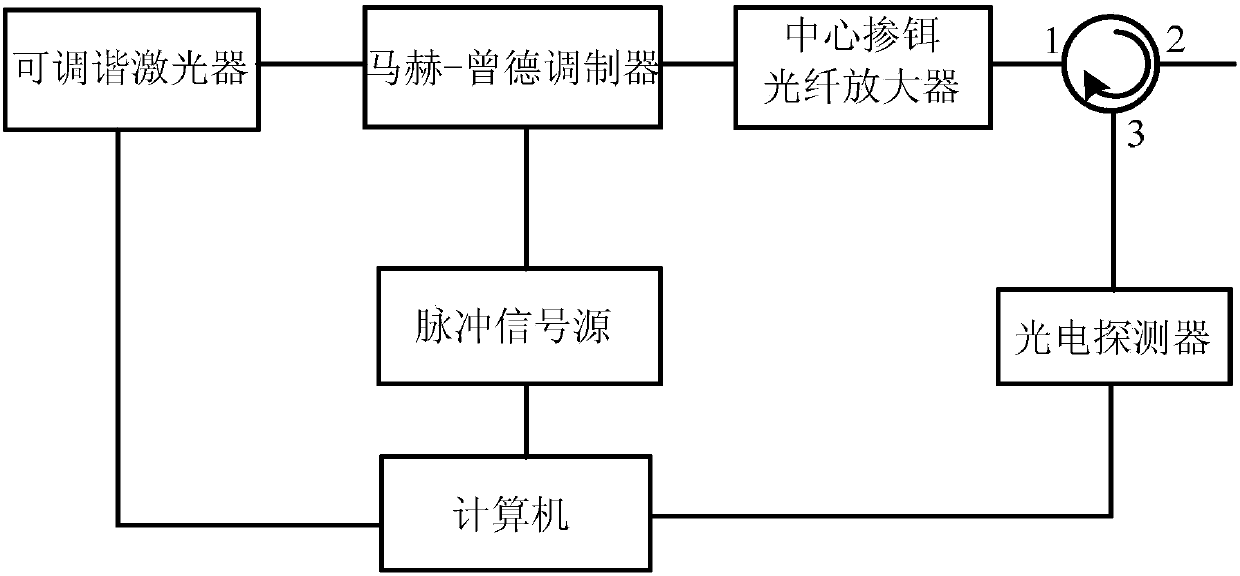

[0032] The role of the control center 1-1 is to provide light sources, demodulate sensing signals, and realize the control of optical switches and programmable o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com