An economical air-cooled dual-phase low yield ratio steel plate and its production process

A low-yield-ratio, economical technology, applied in the field of low-yield-ratio steel plates, can solve problems such as low production efficiency, cost increase, and long production cycle, and achieve high production efficiency, low cost, and loose production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

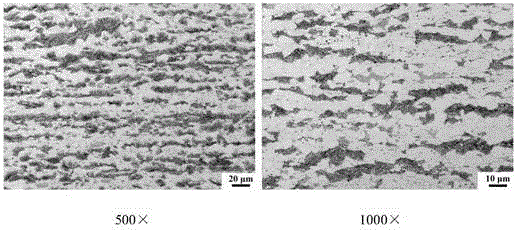

Image

Examples

Embodiment 1

[0026] The steel consists of the following components (wt%): C: 0.08%, Si: 0.80%, Mn: 2.0%, P≤0.015%, S≤0.008%, Cr: 0.90%, the rest is Fe and unavoidable impurities , and the Mn / C ratio is 25, and the Si+Mn+Cr content is 3.7%.

[0027] 1) Smelt and continuously cast slabs according to the above ingredients, and heat the continuous casting slabs at a heating temperature of 1150-1180°C;

[0028] 2) Controlled rolling, rough rolling starting temperature ≤ 990°C, rough rolling finish rolling temperature ≥ 900°C, rough rolling total reduction is 35-65%, then wait for temperature; use intermediate cooling device for watering Cooling, when the temperature is cooled below 800°C, finish rolling is carried out, the finish rolling start temperature is 780-800°C, the finish rolling finish temperature is 700-720°C, the total reduction of finish rolling is 45-75%; the finished plate The thickness is 15mm, and after rolling, it is placed on a cooling bed and air-cooled to room temperature. ...

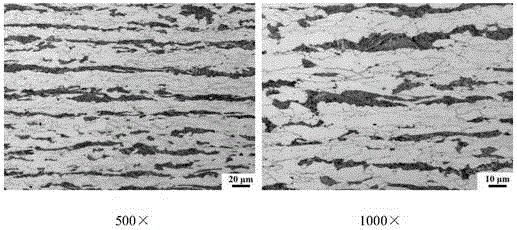

Embodiment 2

[0031] The steel consists of the following components (wt%): C: 0.08%, Si: 0.80%, Mn: 1.9%, P≤0.015%, S≤0.008%, Cr: 0.9%, the rest is Fe and unavoidable impurities , and satisfy the Mn / C ratio of 23.8, and the Si+Mn+Cr content of 3.6%.

[0032] 1) Smelt and continuously cast slabs according to the above ingredients, and heat the continuous casting slabs at a heating temperature of 1150-1180°C;

[0033] 2) Controlled rolling, rough rolling starting temperature ≤ 990°C, rough rolling finish rolling temperature ≥ 900°C, rough rolling total reduction is 35-65%, then wait for temperature; use intermediate cooling device for watering Cooling, when the temperature is cooled below 800°C, finish rolling is carried out, the finish rolling start temperature is 780-800°C, the finish rolling finish temperature is 700-720°C, the total reduction of finish rolling is 45-75%; the finished plate The thickness is 15mm, and after rolling, it is placed on a cooling bed and air-cooled to room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com