Alkaline pectase mutant with improved heat resistance

A pectinase and mutant technology, applied in the field of bioengineering, can solve problems such as high potency and research that cannot be ignored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The construction of embodiment 1 mutant expression plasmid and the acquisition of recombinant Bacillus subtilis

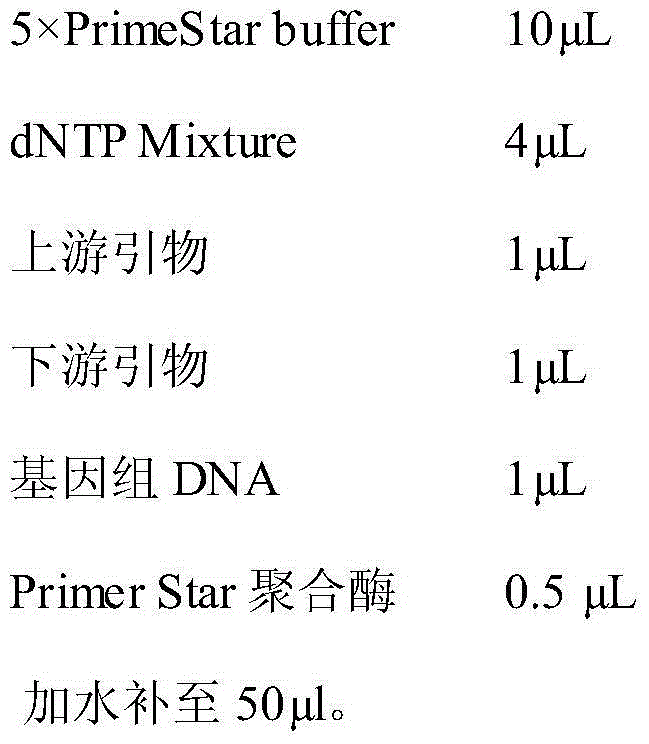

[0027] 1. Construct a mutant expression vector using the pET-20b(+)-pgl plasmid as a template

[0028] The nucleotide sequence of the gene encoding wild-type alkaline pectinase and signal peptide consisting of 21 amino acids is shown in SEQ ID NO.1, and the amino acid sequence of wild-type mature alkaline pectinase is shown in SEQ ID NO.2 shown. By comparing the heat-resistant pectinase sequences: CAD56882 from Bacillus licheniformis, BAA96478 from Bacillus sp.strain P-4-N, and AAD35518 from Thermotoga maritima MSB82, the optimum temperatures are 69°C, 70°C and 90°C, respectively. Combined with the three-dimensional structure of alkaline pectinase, it is speculated that the isoleucine I at position 325 has a greater impact on the thermal stability of alkaline pectinase, and a mutation experiment was designed to mutate the isoleucine I at position 325 into ...

Embodiment 2

[0041] Expression of embodiment 2 mutant PGL

[0042] Seed medium composition (g / L): yeast powder 5, tryptone 10, NaCl 10, glucose 20, pH 7.0.

[0043] Composition of fermentation medium: yeast powder 24g / L, tryptone 12g / L, glycerol 5g / L, K 2 HPO 4 72 mmol L -1 , KH 2 PO 4 17mmol L -1 .

[0044] Inoculate the recombinant strain E.coli BL21(DE3) containing the mutant expression vector pET-20b(+)-pglI325F from a glycerol tube into 100 μg mL -1 In the seed medium of ampicillin, the filling volume is 20mL / 250mL. The culture temperature was 37° C., and the culture was shaken on a shaker at 200 rpm for 10 h.

[0045] The seed solution cultivated for 10 h was inoculated with 3% (V / V) inoculum containing 100 μg mL -1 In the fermentation medium of ampicillin, the filling volume is 50mL / 500mL, at 37°C, 200r min -1 nourish. Bacteria grow to a certain stage (OD 600 =0.6), adding a final concentration of 0.4mM IPTG for induction, while adjusting the temperature to 30°C, and ind...

Embodiment 3

[0046] Enzymatic properties of PGL before and after mutation in embodiment 3

[0047] According to the method described in Example 2, E.coli BL21(DE3) containing the unmutated expression vector pET-20b(+)-pgl and the mutant strain E.coli BL21(DE3)(pET-20b(+) -pglI325F) was fermented, and the enzymes in the fermentation broth were purified and analyzed for enzymatic properties such as heat resistance. The resulting alkaline pectinase mutant was named I325F.

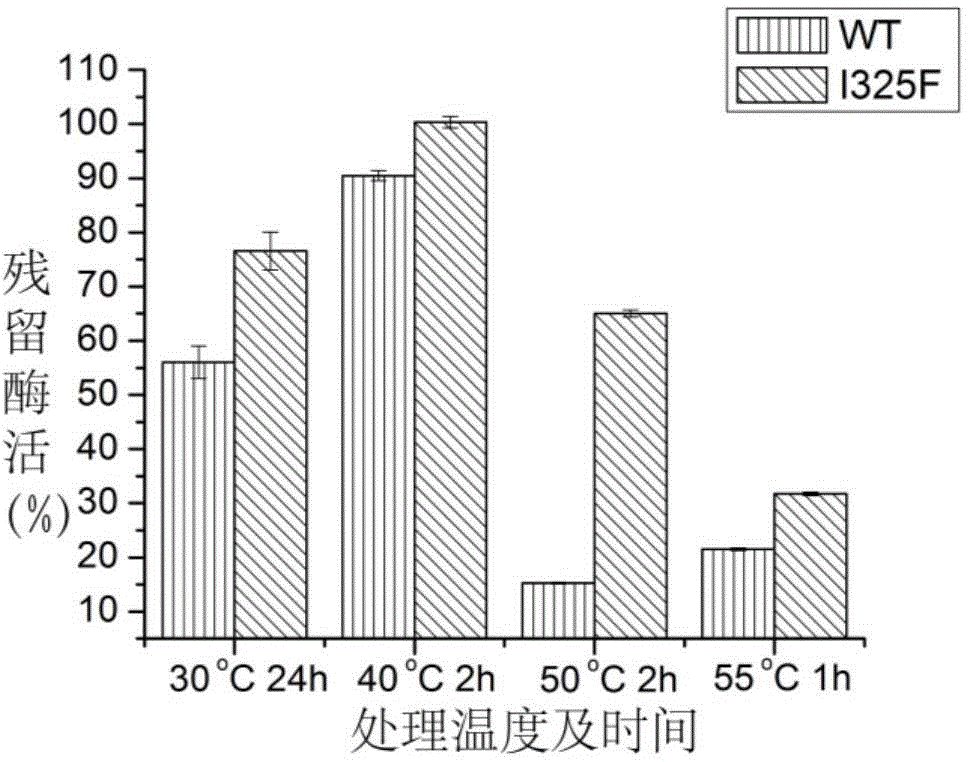

[0048] Depend on figure 1 It can be seen that the enzyme activity loss of alkaline pectinase (WT) before mutation is obvious after incubation at 30°C for 24h, 50°C for 2h, and 55°C for 1h; After the same treatment, the residual enzyme activity was increased compared with that before the mutation, especially when incubated at 50°C for 2 hours. After incubation at 50°C for 2 hours, the residual enzyme activity after mutation was 4.27 times that before mutation; this shows that the heat resistance of the mutated alkaline p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com