A kind of method for preparing liraglutide

A technology of liraglutide and synthesis method, which is applied in the field of preparation of polypeptide drugs, and can solve problems such as long synthesis cycle, many impurities, and unsuitability for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

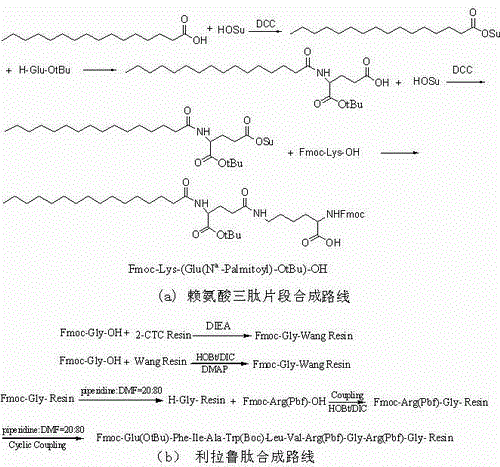

Method used

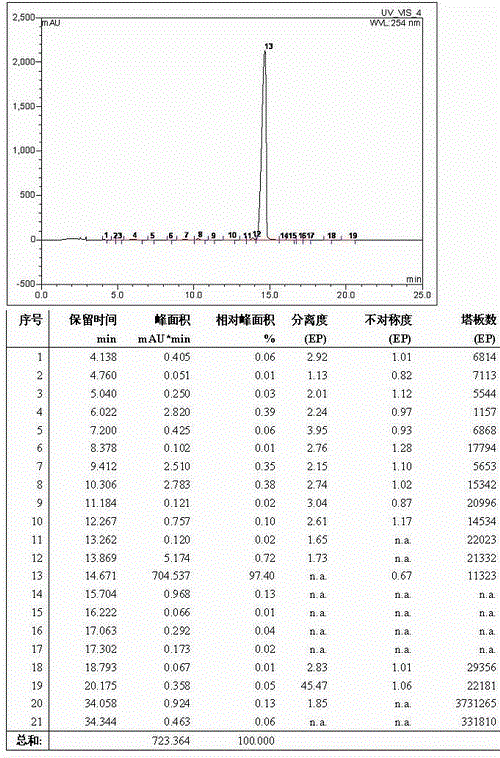

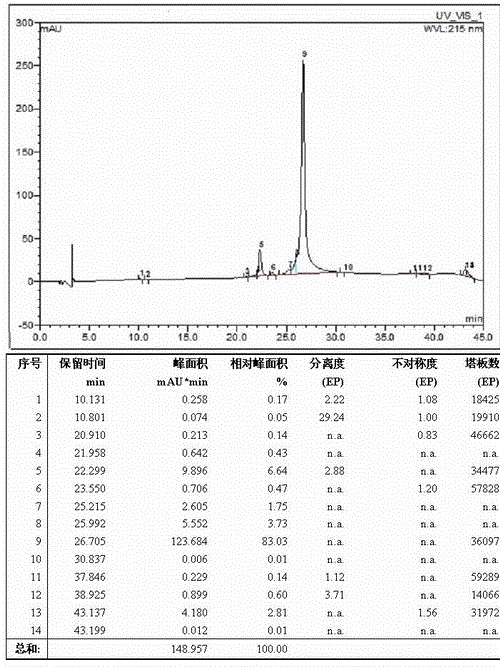

Image

Examples

Embodiment 1

[0089] Embodiment one: the synthesis of Palmitoyl-OSu activated lipid

[0090] Weigh 256.42g n-hexadecanoic acid (1.0mol), add 138.10g HOSu (1.2mol) into 2000ml THF, add 247.56g DCC (1.2mol) under ice-water bath, react for 1 hour, warm up to room temperature for 3 hours, and react Liquid filtration, mother liquor spin-dried, dissolved in DCM, filtered, washed 3 times with saturated sodium bicarbonate, 2 times with pure water, back-extracted 2 times, combined organic phase, dried with anhydrous sodium carbonate, spin-dried, 0-5°C ice ethanol Recrystallize 3 times, filter, and dry the solid oil pump to obtain 314.62g Palmitoyl-OSu activated lipid, yield 89%.

Embodiment 2

[0091] Embodiment two: the synthesis of Palmitoyl-Glu-OtBu

[0092] Weigh 101.62g H-Glu-OtBu (0.5mol) and 79.50g Na 2 CO 3 (0.75mol) was added to the mixed solution of 500ml water and 500ml THF to dissolve, and 176.75g Palmitoyl-OSu (0.5mol) was weighed and added to 500ml THF. Adjust the pH to 7 with dilute hydrochloric acid, remove THF by rotary evaporation, and then adjust the pH to 3. A large white precipitate was obtained which was filtered. The resulting white precipitate was recrystallized from 0-5°C ice-cold ethanol. The solid oil pump was dried to obtain 192.11g Palmitoyl-Glu-OtBu, yield 87%.

Embodiment 3

[0093] Example 3: Synthesis of Palmitoyl-Glu(OSu)-OtBu

[0094] Weigh 88.33g Palmitoyl-Glu-OtBu (0.2mol), add 27.62g HOSu (0.24mol) into 1000ml THF, add 49.51g DCC (0.24mol) under ice-water bath, react for 1 hour, warm up to room temperature for 3 hours, react Liquid filtration, mother liquor spin-dried, dissolved in DCM, filtered, washed 3 times with saturated sodium bicarbonate, 2 times with pure water, back-extracted 2 times, combined organic phase, dried with anhydrous sodium carbonate, spin-dried, 0-5°C ice ethanol Recrystallize 3 times, filter, and dry the solid oil pump to obtain 94.81g Palmitoyl-Glu(OSu)-OtBu activated fat, with a yield of 88%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com