Preparation method of tungsten bronze profile

A technology of tungsten bronze and hydrogen tungsten bronze, applied in the field of preparation of tungsten bronze type materials, can solve the problems of limited amount of single synthesis, high energy consumption of mechanical ball milling, and restriction of wide application, etc., achieving simple equipment and long synthesis cycle. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a tungsten bronze material, the preparation method is as follows:

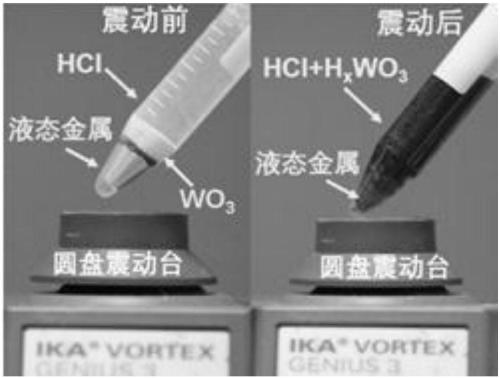

[0037] 100nm WO 3 The powder and liquid metal (Ga 75.5%, In 24.5%) and hydrochloric acid, the pH value is 0.3, are mixed according to the mass ratio of 1:5:5, the temperature of the mixed solution is selected as 20 ℃, and put into a polyethylene centrifuge tube Vibration and mixing, the choice of vibration mixing is to vibrate on a disc vibrator for 2 minutes. The prepared mixture first separates the liquid metal from the mixed solution, and the separated liquid metal is placed in 1mol / L hydrochloric acid for recycling. The separated powder is mixed with hydrochloric acid. The mixed solution was centrifuged with a centrifuge, and the powder obtained after centrifugation was washed with alcohol, deionized water, and alcohol in sequence. After cleaning, the hydrogen tungsten bronze was placed in a vacuum drying oven and dried at 20°C for 30 minutes. See attached for vibration pre...

Embodiment 2

[0039] This embodiment provides a tungsten bronze material, the preparation method is as follows:

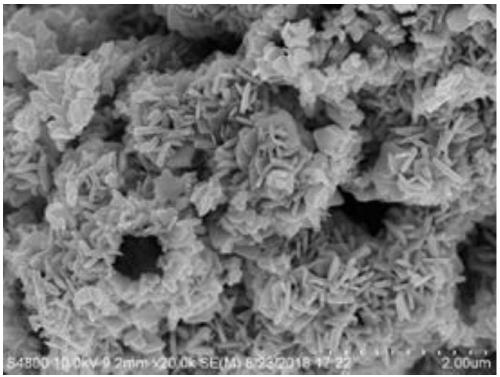

[0040] 50nmWO 3 The powder and liquid metal (Ga 75.5%, In 24.5%) and hydrochloric acid, the pH value is 0, are mixed according to the mass ratio of 2:5:2, the temperature of the mixed solution is selected as 40 ° C, and put into a polyethylene centrifuge tube Vibration and mixing, the choice of vibration mixing is to vibrate on a disc vibrator for 1min. The prepared mixture first separates the liquid metal from the mixed solution, and the separated liquid metal is placed in 1mol / L hydrochloric acid for recycling. The separated powder is mixed with hydrochloric acid. The mixed solution was centrifuged with a centrifuge, and the powder obtained after centrifugation was washed with alcohol, deionized water, and alcohol in sequence. After cleaning, the hydrogen tungsten bronze powder was placed in a vacuum drying oven and dried at 40°C for 20 minutes. The SEM image of the prepared ...

Embodiment 3

[0042] This embodiment provides a tungsten bronze material, the preparation method is as follows:

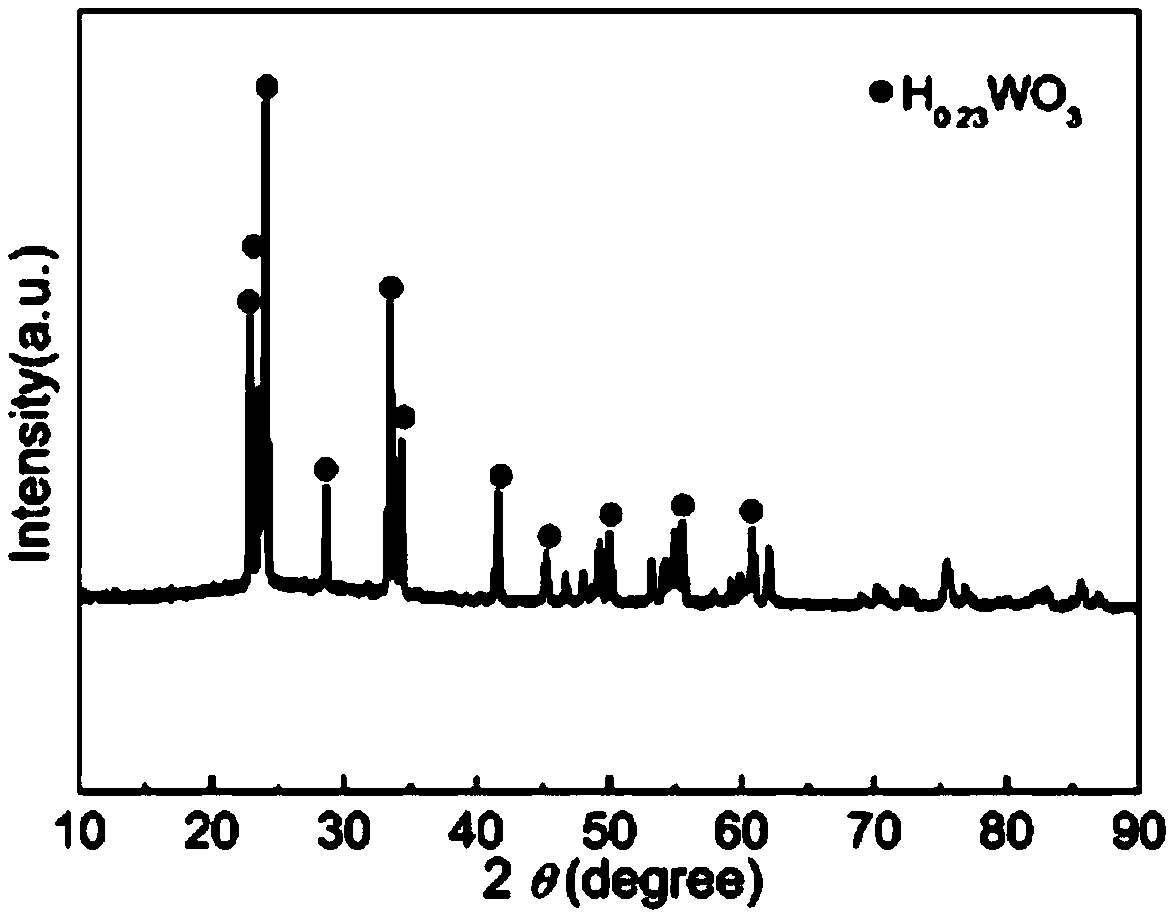

[0043] 50nmWO 3 The powder is mixed with Ga 67%, In 20.5%, Sn 12.5% and hydrochloric acid, the pH value is 0, according to the mass ratio of 1:5:10, the temperature of the mixed solution is selected as 60 ° C, and put into a polyethylene centrifuge tube Medium vibration mixing, vibration mixing is selected as vibration on a disc vibrator for 5 minutes, the prepared mixture is first separated from the liquid metal and the mixed solution, the separated liquid metal is placed in 1mol / L hydrochloric acid for recycling, and the separated powder is mixed with hydrochloric acid The mixed solution was centrifuged with a centrifuge, and the powder obtained after centrifugation was washed with alcohol, deionized water, and alcohol in sequence, and the hydrogen tungsten bronze powder of the cleaned thickness was placed in a vacuum drying oven and dried at 60°C for 5 minutes. The macrosc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com