Preparation method of BCTZ-xBi<3+> system multifunctional electronic ceramic powder

An electronic ceramic, bctz-xbi3 technology, applied in the field of preparation of BCTZ-xBi3+ system multifunctional electronic ceramic powder, can solve the problems of few studies on relaxor ferroelectrics, achieve shortened sintering time, short production cycle, The effect of uniform distribution of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

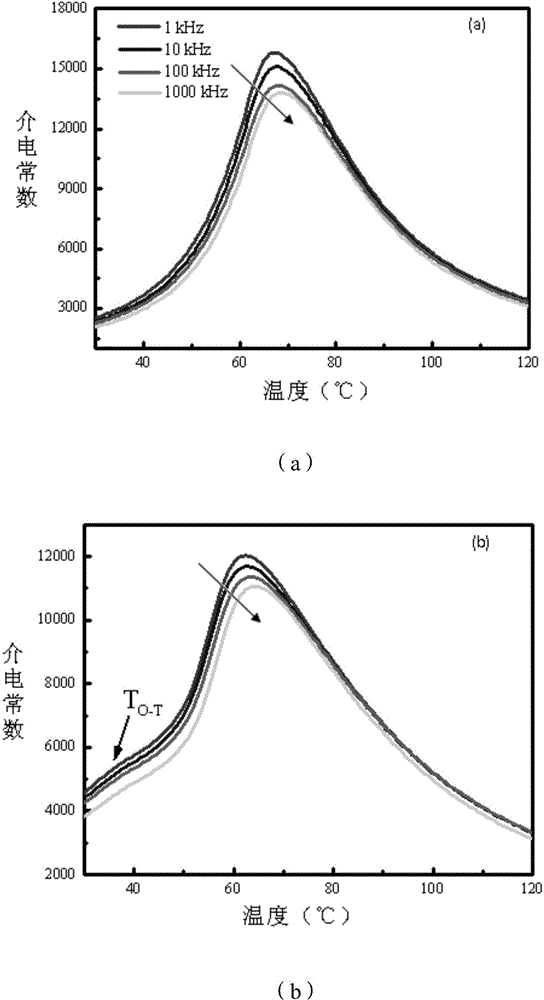

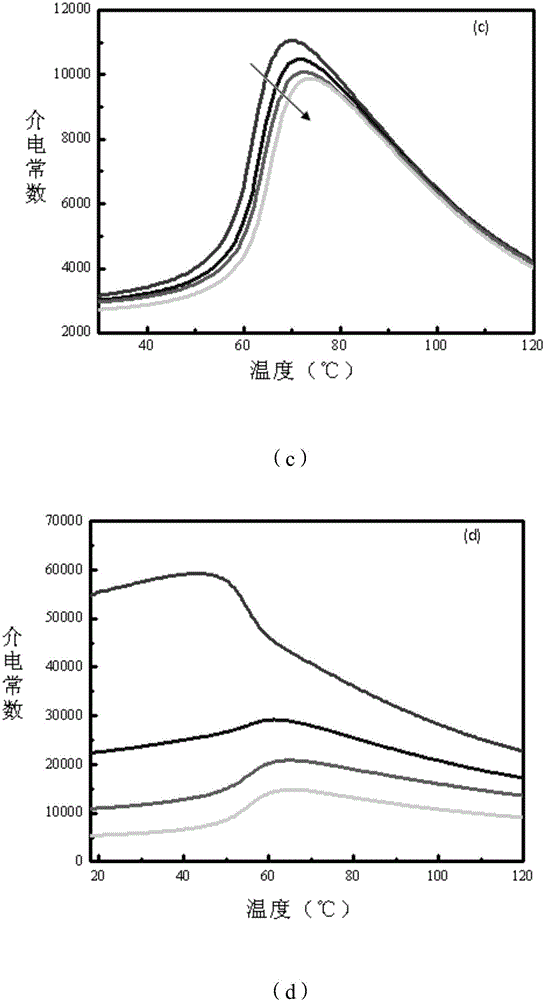

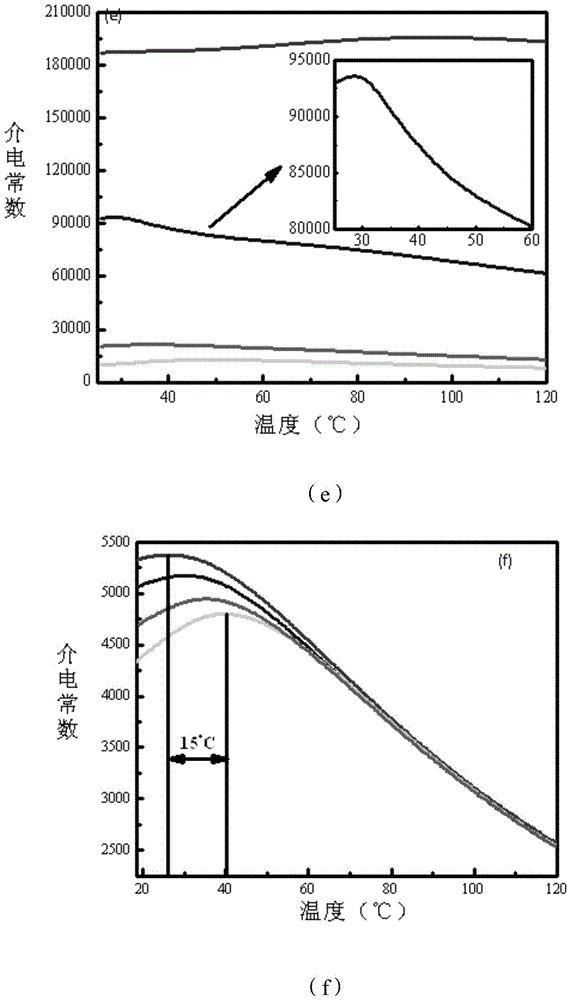

Image

Examples

Embodiment 1

[0039] A BCTZ-xBi 3+ The preparation method of system multifunctional electronic ceramics comprises the following steps:

[0040] 1) Press Ba:Ca:Zr:Bi=0.9:0.1:0.1:0.005 molar ratio, BaCl 2 2H 2 O, CaCl 2 , ZrOCl 2 ·8H 2 O and Bi(NO 3 ) 3 Dissolve in water respectively, fully stir until completely dissolved, then mix the aqueous solutions of the four substances to obtain a mixed solution;

[0041] 2) According to Ti: Ba: [OH - ]=1:1:5 molar ratio, TiCl 4 Add NaOH and NaOH into the mixed solution, stir well until the mixed solution is white and viscous, and obtain BCTZ-0.005Bi 3+ System powder precursor;

[0042] 3) BCTZ-xBi 3+ The powder precursor of the system is placed in a hydrothermal reaction kettle, and after 15 hours of heat preservation reaction at 150°C, it is cooled to room temperature to obtain BCTZ-xBi 3+ System powder; wherein, the filling degree of the hydrothermal reactor is 60%;

[0043] 4) BCTZ-0.005Bi 3+ After the system powder was washed with de...

Embodiment 2

[0046] A BCTZ-xBi 3+ The preparation method of system multifunctional electronic ceramics comprises the following steps:

[0047] 1) According to the molar ratio of Ba: Ca: Zr: Bi=0.9:0.1:0.1:0.010, BaCl 2 2H 2 O, CaCl 2 , ZrOCl 2 ·8H 2 O and Bi(NO 3 ) 3 Dissolve in water respectively, fully stir until completely dissolved, then mix the aqueous solutions of the four substances to obtain a mixed solution;

[0048] 2) According to the molar ratio of Ti:Ba:[OH-]=1:1:6, TiCl 4 Add NaOH and NaOH into the mixed solution, stir well until the mixed solution is white and viscous, and obtain BCTZ-0.010Bi 3+ System powder precursor;

[0049] 3) BCTZ-0.010Bi 3+ The powder precursor of the system is placed in a hydrothermal reaction kettle, and after 14 hours of heat preservation reaction at 160 ° C, it is cooled to room temperature to obtain BCTZ-xBi 3+ System powder; wherein, the filling degree of the hydrothermal reactor is 70%;

[0050] 4) BCTZ-0.010Bi 3+ After the system ...

Embodiment 3

[0053] A BCTZ-xBi 3+ The preparation method of system multifunctional electronic ceramics comprises the following steps:

[0054] 1) According to the molar ratio of Ba: Ca: Zr: Bi=0.9:0.1:0.1:0.015, BaCl 2 2H 2 O, CaCl 2 , ZrOCl 2 ·8H 2 O and Bi(NO 3 ) 3 Dissolve in water respectively, fully stir until completely dissolved, then mix the aqueous solutions of the four substances to obtain a mixed solution;

[0055] 2) According to Ti: Ba: [OH - ]=1:1:7 molar ratio, TiCl 4 Add NaOH and NaOH into the mixed solution, stir well until the mixed solution is white and viscous, and obtain BCTZ-0.015Bi 3+ System powder precursor;

[0056] 3) BCTZ-0.015Bi 3+ The powder precursor of the system is placed in a hydrothermal reaction kettle, and after 15 hours of heat preservation reaction at 150°C, it is cooled to room temperature to obtain BCTZ-0.015Bi 3+ System powder; wherein, the filling degree of the hydrothermal reactor is 60%;

[0057] 4) BCTZ-0.015Bi 3+ After the system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com