Strong-strength strong cubic texture layered composite base strip and preparing method thereof

A strong cubic texture and layered composite technology, applied in coatings, manufacturing tools, heat treatment equipment, etc., can solve the problems of difficult to realize industrial production, difficult to form cubic texture, increase production costs, etc., and achieve high substrate strength, The effect of uniform and fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

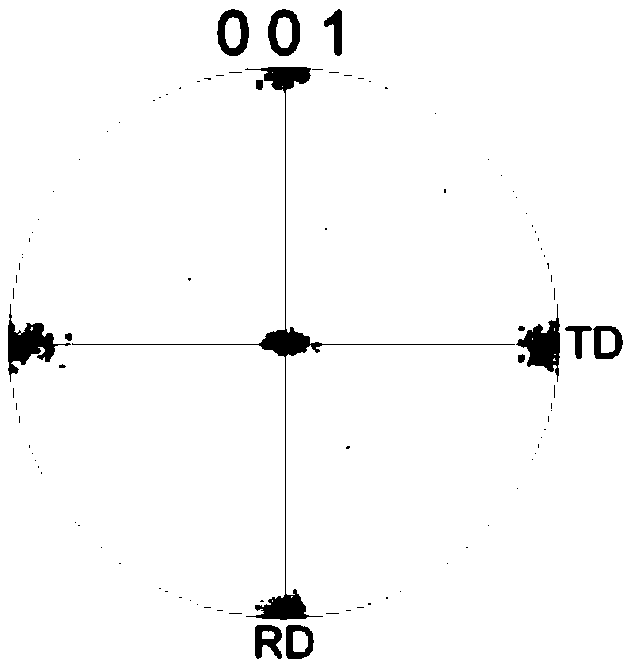

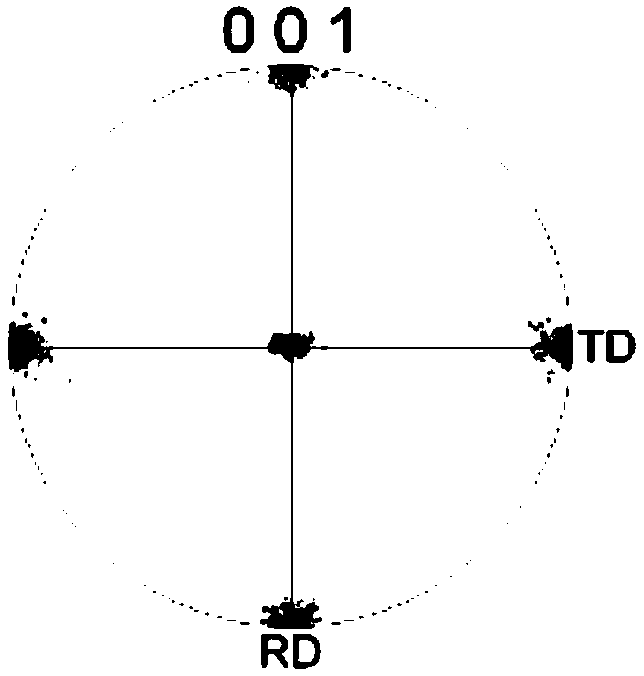

Image

Examples

Embodiment 1

[0021] The steps of the preparation method of the inventive method embodiment 1 are as follows:

[0022] (1) Alloy smelting and hot rolling

[0023] Continuous casting technology is used to obtain nickel-tungsten alloy ingot with 12% tungsten atomic percentage, the thickness is 600mm, and then rough rolling is directly carried out to 60mm thickness. Then finish rolling at 1250°C for 20 minutes to a thickness of 12mm, the rolling pass is 3 passes, and the hot-rolled plate is obtained by water quenching immediately after the last hot rolling pass;

[0024] (2) Cold rolling of hot rolled sheet

[0025] After grinding and descaling the surface of the above-mentioned hot-rolled sheet, cold-rolling is carried out, and finally cold-rolled to a thickness of 95 μm to obtain a cold-rolled strip;

[0026] (3) Deposition of alloy film

[0027] Adopt magnetron sputtering method to deposit 30nm thick alloy film on the above-mentioned cold-rolled strip surface, the composition of this all...

Embodiment 2

[0032] The steps of the preparation method of the embodiment of the present invention 2 are as follows:

[0033] (1) Alloy smelting and hot rolling

[0034] Continuous casting technology is used to obtain nickel-tungsten alloy ingot with 12% tungsten atomic percentage, the thickness is 600mm, and then rough rolling is directly carried out to 60mm thickness. Then finish rolling at 1250°C for 20 minutes to a thickness of 12mm, the rolling pass is 3 passes, and the hot-rolled plate is obtained by water quenching immediately after the last hot rolling pass;

[0035] (2) Cold rolling of hot rolled sheet

[0036] After grinding and descaling the surface of the above-mentioned hot-rolled sheet, cold-rolling is carried out, and finally cold-rolled to a thickness of 95 μm to obtain a cold-rolled strip;

[0037] (3) Deposition of alloy film

[0038] Adopt magnetron sputtering method to deposit 30nm thick alloy film on the above-mentioned cold-rolled strip surface, the composition of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com