A scraped rectification tower for refining adiponitrile and adiponitrile refining process

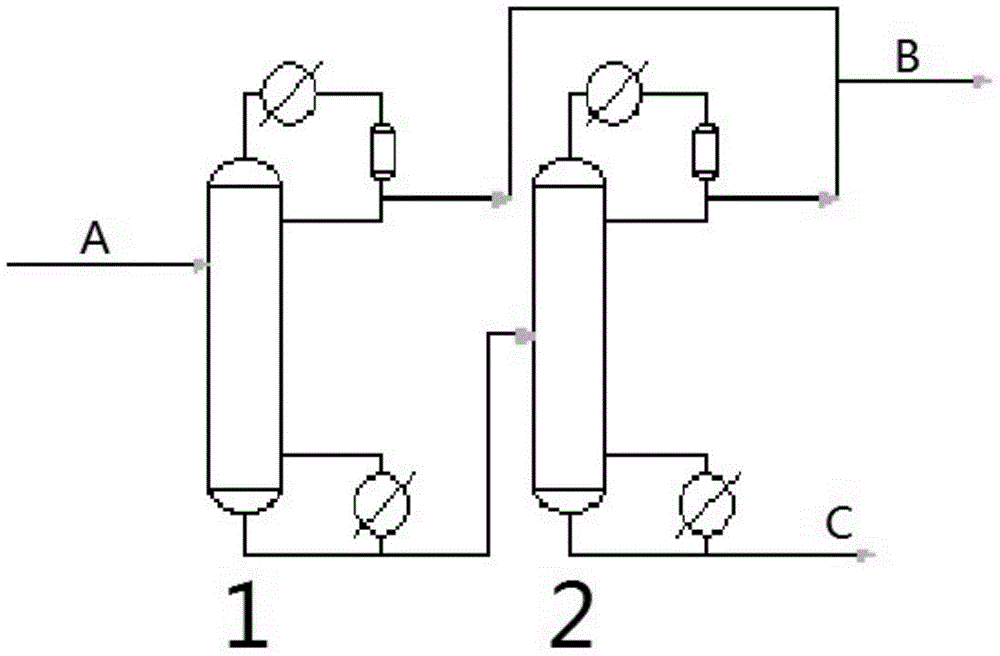

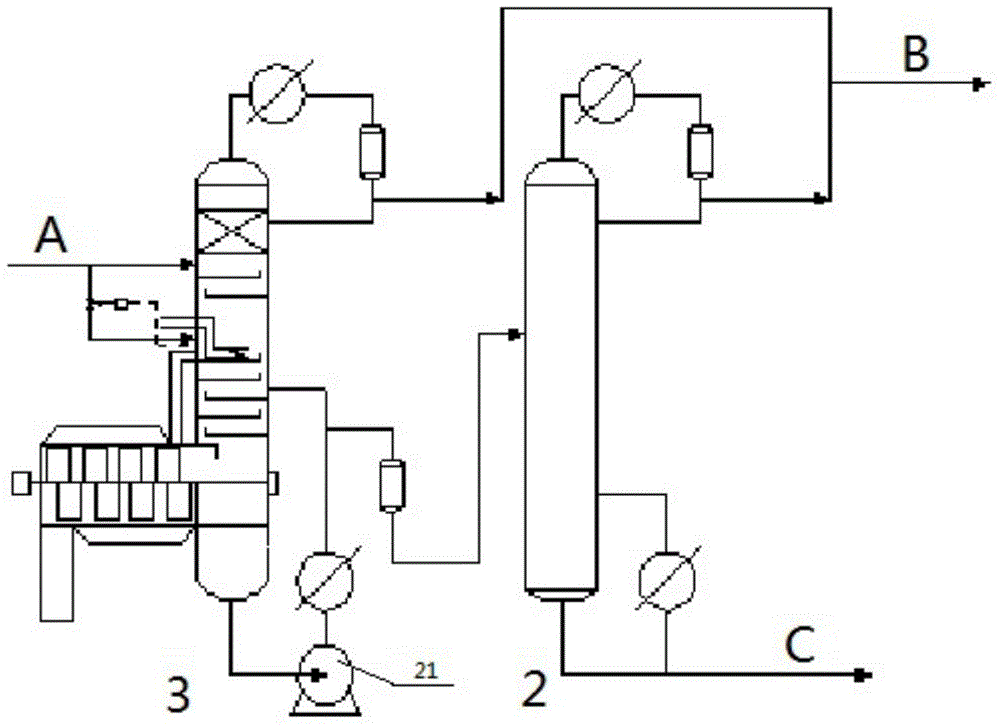

A rectification tower and adiponitrile technology, applied in fractionation, carboxylic acid nitrile purification/separation, organic chemistry, etc., can solve the problems of easy coking of materials, influence of separation degree, low rectification rate, etc., to increase reliability and Stability, avoiding coking and clogging, and improving the effect of product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

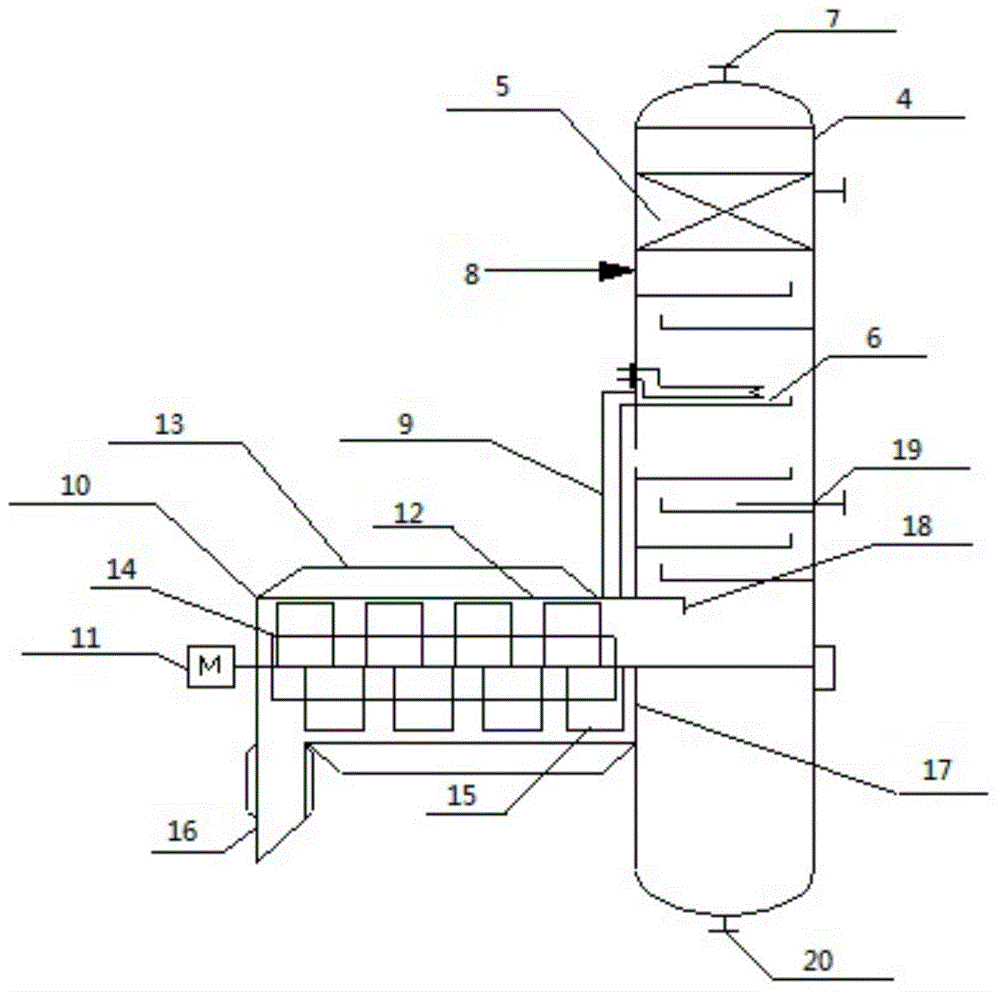

[0032] The crude adiponitrile product A before rectification contains 90% of adiponitrile, 9% of heavy components, and 1% of precipitated solid impurities. Because the initial concentration of the material entering the scraped rectification tower 3 is low, after the material enters the scraped rectification tower 3, along with the steaming of adiponitrile, the concentration of precipitated solid impurities dissolved in the adiponitrile solution rises, and the control tower The temperature at the plate temperature measurement point is 160-180°C, correspondingly, the temperature at the scraped evaporator 10 is 250-280°C, the system pressure is 3KPaA, and the speed of the scraped evaporator 10 is 60-100r / min. In embodiment 1, the refined adiponitrile product B above 99.9% can be obtained from the top of scraped rectification tower 3, and the bottom of scraped rectification tower 3 does not contain solid impurities that can be separated out. 98.6% of the refined adiponitrile produ...

Embodiment 2

[0034] The crude adiponitrile product A before rectification contains 50% of adiponitrile, 45% of heavy components, and 5% of solid impurities can be separated out. Because the initial concentration of the material entering the scraped rectification tower 3 is low, after the material enters the scraped rectification tower 3, along with the steaming of adiponitrile, the concentration of precipitated solid impurities dissolved in the adiponitrile solution rises, and the control tower The temperature at the plate temperature measurement point is 160-180°C, correspondingly, the temperature at the scraped evaporator 10 is 240-260°C, the system pressure is 1KPaA, and the speed of the scraped evaporator 10 is 100-150r / min. In embodiment 2, the refined adiponitrile product B above 99.9% can be obtained from the top of the scraped rectification tower 3, and the bottom of the scraped rectification tower 3 does not contain solid impurities that can be separated out. 98.0% of the purified...

Embodiment 3

[0036] The crude adiponitrile product A before rectification contains 90% of adiponitrile, 9% of heavy components, and 1% of precipitated solid impurities. Because the initial concentration of the material entering the scraped rectification tower 3 is low, after the material enters the scraped rectification tower 3, along with the steaming of adiponitrile, the concentration of precipitated solid impurities dissolved in the adiponitrile solution rises, and the control tower The temperature at the plate temperature measuring point is 160-180°C, correspondingly, the temperature at the scraped evaporator 10 is 200-240°C, the system pressure is 1KPaA, and the speed of the scraped evaporator 10 is 150-200r / min. In embodiment 3, the refined adiponitrile product B above 99.9% can be obtained from the top of the scraped rectification tower 3, and the bottom of the scraped rectification tower 3 does not contain solid impurities that can be separated out. 98.0% of the purified adiponitri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com