Method for raising biocompatibility of polyester fiber artificial ligament by graphene modification

A technology of biocompatibility and artificial ligament, applied in medical science, prosthesis, coating, etc., to achieve good repeatability, accelerate bone healing, and improve biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

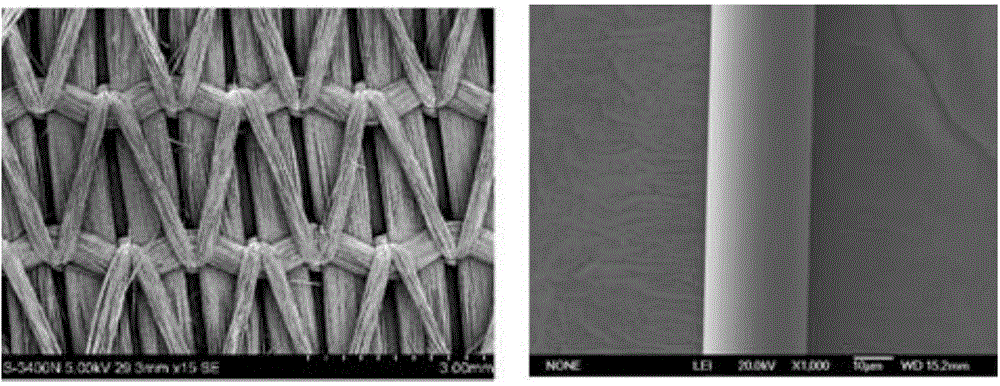

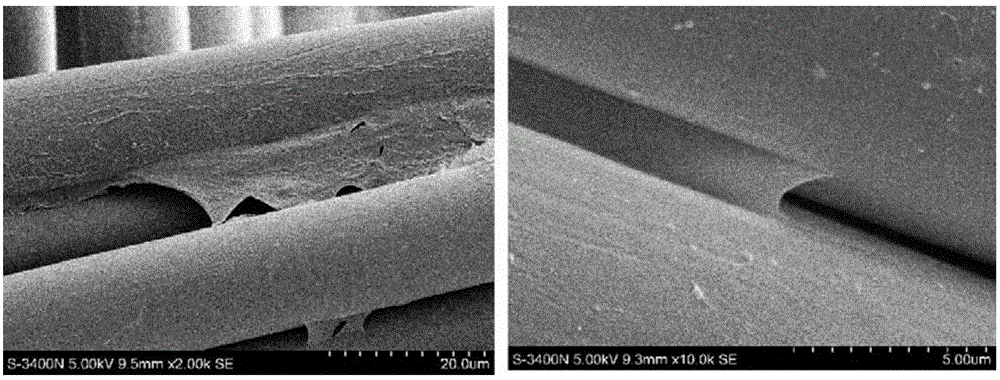

Image

Examples

preparation example Construction

[0041] A. Preparation of graphene: (1) Copper foil is placed in a CVD reaction furnace. (2) Under the condition of 3kPa, the reaction furnace is heated to 1000°C, with CH4 as the carbon source, H 2 It is a reducing gas, and Ar is an inert gas, which is passed into the reaction furnace. (3) Return to room temperature after reacting for 10 minutes to obtain uniform single-layer graphene grown on copper foil.

[0042] B. Preparation of graphene transfer film: (1) Spin-coat polymethyl methacrylate PMMA (2) on the graphene copper foil prepared on-site at 3000r / min and put the copper foil on a heating plate at 150°C for baking Bake for 15 minutes to solidify the glue. (3) Dissolve the baked copper foil in ammonium sulfate solution for 24 hours to corrode the Cu substrate. (4) After corroding the copper substrate, obtain a PMMA film floating on the surface of the ammonium sulfate solution and adhered with single-layer graphene. (5) Transfer the obtained PMMA film to deionized wat...

Embodiment 1

[0047] This embodiment proceeds according to the following steps:

[0048] 1. First place 10X10cm25μm thick copper foil (99.9%) into a CVD reaction furnace with a diameter of 8cm by crimping. Then, under the Ar gas atmosphere, the temperature was raised to 1000°C under the condition of 3kPa, the Ar gas flow was maintained at 200sccm (1sccm=1mL / min), and the heating rate was 10°C / min; when the copper foil reached the target temperature, H 2 Gas reduction annealing, the flow rate is 65sccm, the Ar gas flow rate and temperature remain unchanged: after 20min, 50sccm methane, 65sccmH 2 After growing with 200sccm Ar gas for 10min, turn off methane and hydrogen, and lower the furnace to room temperature at 10°C / s under Ar gas atmosphere. Obtain uniform single-layer graphene grown on copper foil.

[0049] 2. Spin-coat 7% polymethyl methacrylate PMMA on the graphene copper foil prepared on site at 3000r / min. After spin-coating, place the copper foil on a 150°C heating plate and bake f...

Embodiment 2

[0052] This embodiment proceeds according to the following steps:

[0053] 1. First place 10X10cm25μm thick copper foil (99.9%) into a CVD reaction furnace with a diameter of 8cm by crimping. Then the temperature was raised to 1000°C under normal pressure under the Ar gas atmosphere, the Ar gas flow was maintained at 200 sccm (1 sccm = 1mL / min), and the heating rate was 10°C / min; when the copper foil reached the target temperature, H 2 Gas reduction annealing, the flow rate is 65sccm, the Ar gas flow rate and temperature remain unchanged: after 20min, 50sccm methane, 65sccmH 2 After growing with 200sccm Ar gas for 10min, turn off methane and hydrogen, and lower the furnace to room temperature at 10°C / s under Ar gas atmosphere. Obtain uniform single-layer graphene grown on copper foil.

[0054] 2. Spin-coat 7% polymethyl methacrylate PMMA on the graphene copper foil prepared on site at 3000r / min. After spin-coating, place the copper foil on a 150°C heating plate and bake for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com