Per-hardened plastic mould steel

A technology for plastic molds and mold steels, applied in the field of metal materials, can solve the problems of uneven hardness, poor hardenability of large cross-section materials, and poor purity, and achieve the effect of improving polishing performance, improving hardenability, and improving finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The mass percentage of the plastic mold steel 3Cr2MnMo after the alloy phase improvement includes the following composition:

[0032] C: 0.35%;

[0033] Si: 0.55%;

[0034] Mn: 1.52%;

[0035] P: ≤0.008%;

[0036] S: ≤0.0004%;

[0037] Cr: 1.98%;

[0038] Mo: 0.45%;

[0039] Ni: 0.23%;

[0040] Nb: 0.08%;

[0041] Cu: ≤0.11%;

[0042] N: 0.004% (40PPM)

[0043] Fe:: margin.

[0044] The smelting process is as follows:

[0045] Converter provides low-phosphorus and low-sulfur molten steel→EAF deoxidation, degassing and inclusion removal→LF furnace refining→VD vacuum refining——→betting ingot / ESR ingot

[0046] Multi-directional deformation process (process): including the combination of radial and axial forging deformation of die steel and transverse and longitudinal multi-directional deformation.

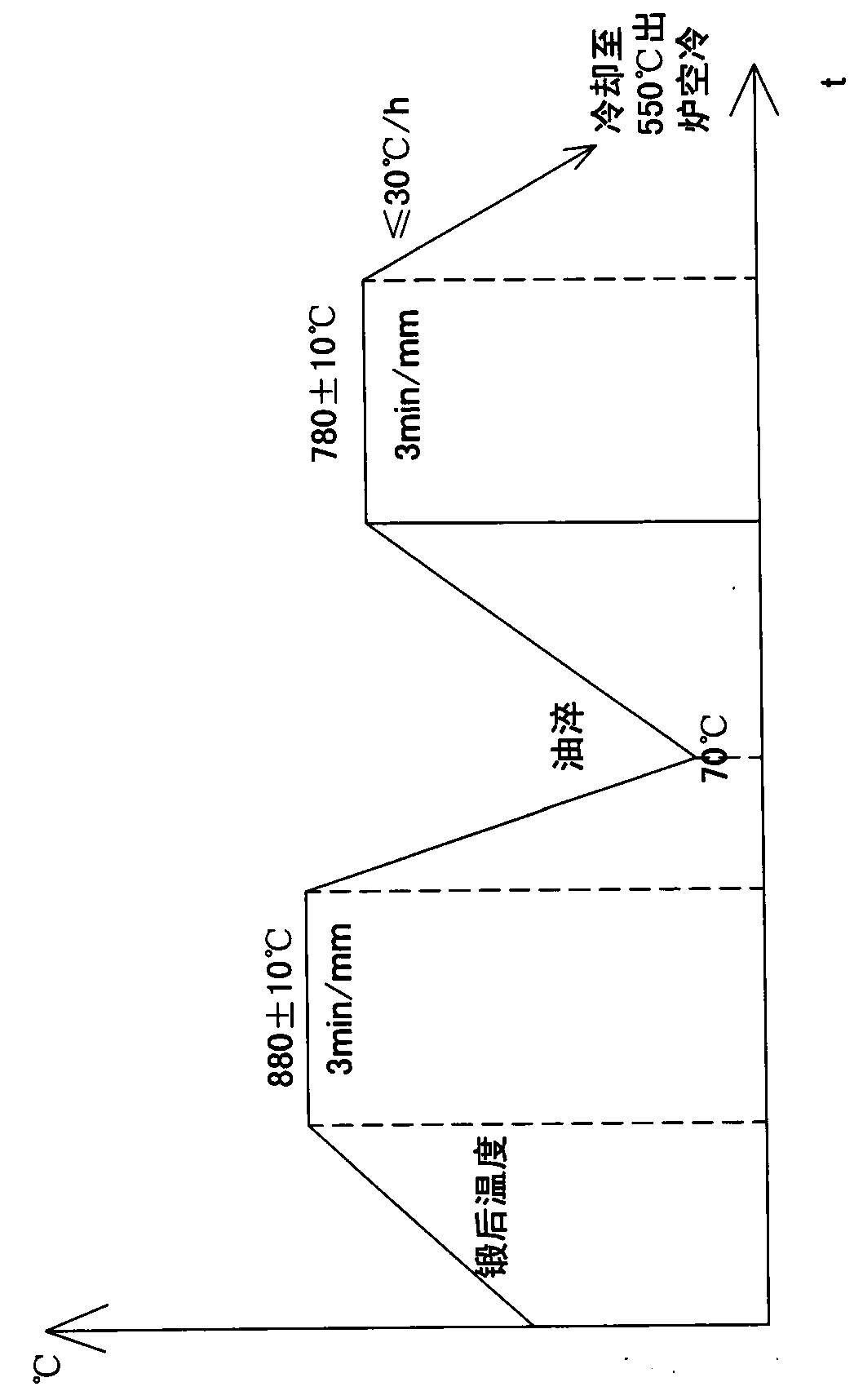

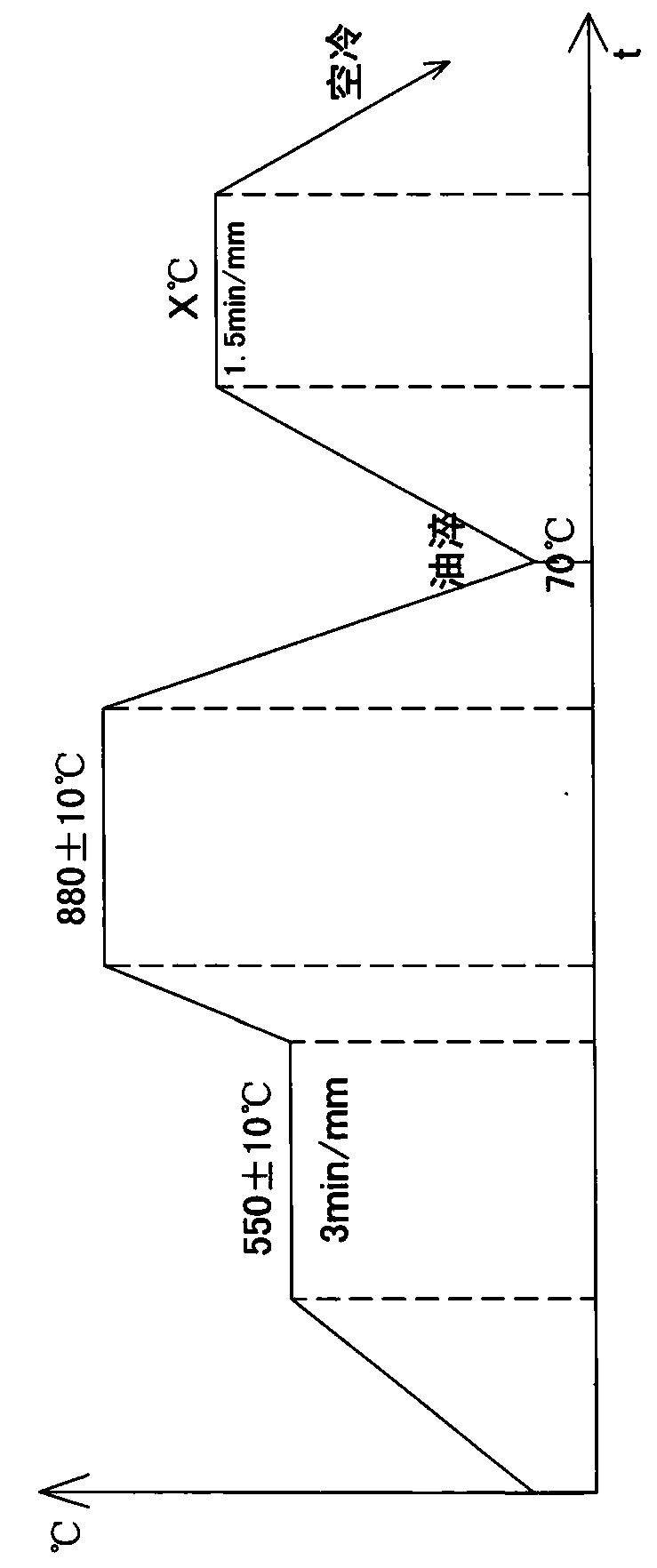

[0047] Refined treatment process (process): Starting from the temperature of the die steel with the thickness of the finished product after forging, heat it to 880...

example 1

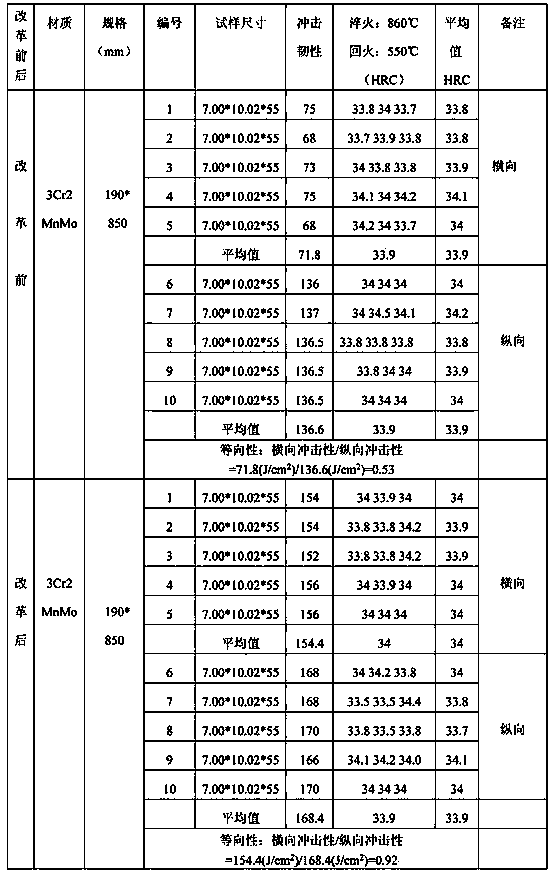

[0049] Example 1 The mechanical impact toughness test results of die steel 3Cr2MnMo before and after improvement are shown in Table 1:

[0050] Table 1

[0051]

[0052] The isotropy of 3Cr2MnMo after the reform is 0.92, and the isotropy of 3Cr2MnMo before the reform is 0.53, compared with an increase of 0.32.

example 2

[0053] Example 2 Die steel 3Cr2MnMo reform before and after polishing performance test results (in terms of polishing roughness),

[0054] Table 2

[0055]

[0056] The roughness of the 3Cr2MnMo polishing material before the reform is much higher than that of the 3Cr2MnMo after the reform, that is, the roughness changes from 0.5 μm to 0.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com