Nanocomposite and nanocomposite furnace tube

A nano-composite material and nano-composite technology, applied in the field of nano-composite furnace tubes, can solve the problems of reducing service life, high-temperature corrosion of furnace tubes, and reducing thermal efficiency, etc., and achieve the effects of preventing coking and heat resistance, saving energy, and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Example 1 A nanocomposite material and nanocomposite furnace tube

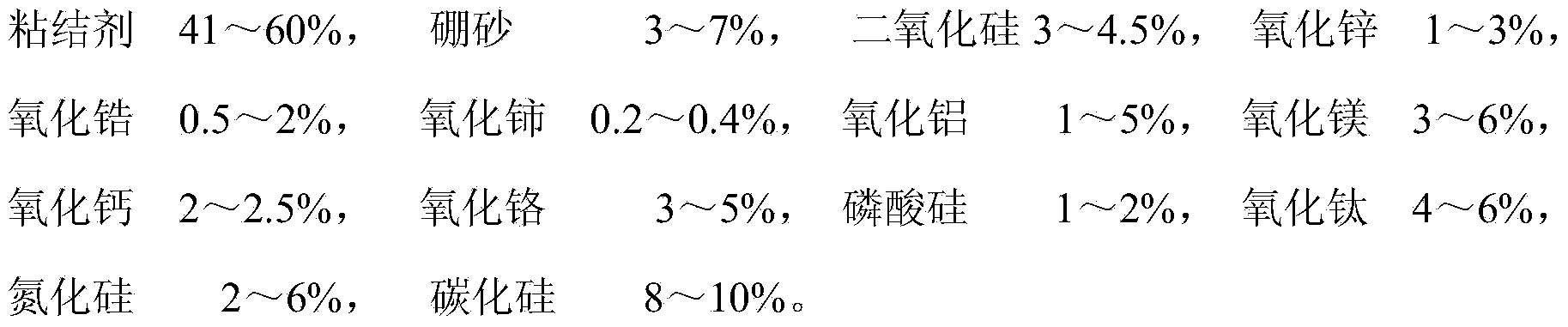

[0010] (1) Composition of nanocomposites

[0011]

[0012] Water glass is used as the adhesive in this embodiment, and water-soluble acrylic resin, styrene-acrylic emulsion or water-soluble silicone resin can also be used.

[0013] (2) Nano composite furnace tube

[0014] The preparation method is as follows: 1) treating the surface of the furnace tube to a certain roughness;

[0015] 2) According to the above proportioning ratio, the nanocomposite material is mixed evenly;

[0016] 3) The nanocomposite material is sprayed onto the surface of the furnace tube, and the thickness is checked with a thickness gauge, which is no more than 30-55 microns;

[0017] 4) Burning the sprayed furnace tube at 500° C. for 2-3 hours to obtain a furnace tube covered with nanocomposite material.

[0018] (3) Effect experiment

[0019] It is used in a heat-conducting oil furnace in a chemical plant. The furnace te...

Embodiment 2

[0020] Example 2 A nanocomposite material and nanocomposite furnace tube

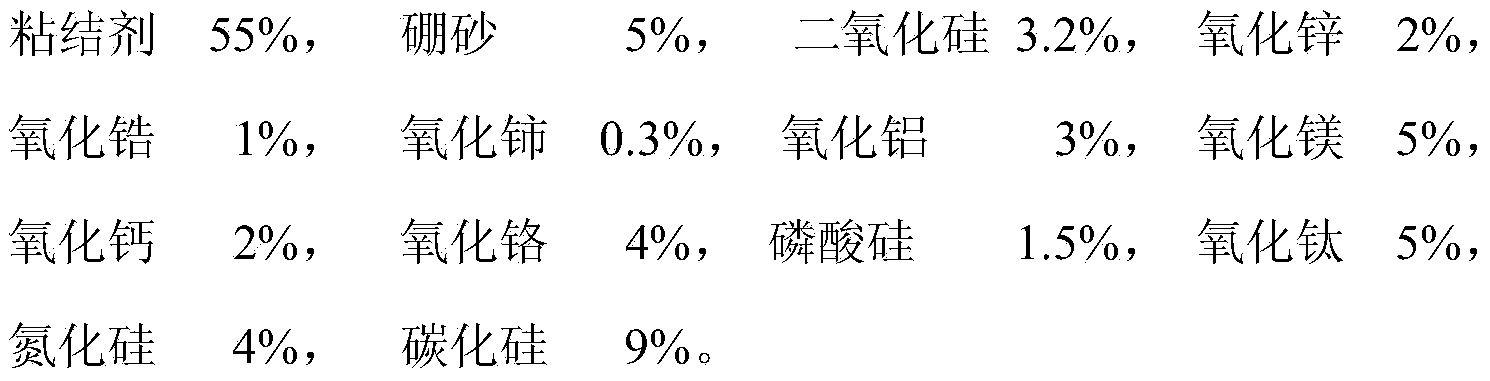

[0021] (1) Composition of nanocomposites

[0022]

[0023] In this embodiment, water-soluble acrylic resin is used as the adhesive, and water glass, styrene-acrylic emulsion or water-soluble silicone resin can also be used.

[0024] (2) Nano composite furnace tube

[0025] The preparation method is as follows: with embodiment 1.

[0026] (3) Effect experiment

[0027] In a power plant in Xinjiang, the units with ordinary furnace tubes suffered serious corrosion, serious contamination and slagging, and decreased energy efficiency and output. After adopting the nanocomposite material furnace tube of the present invention, the furnace temperature was 1300°C, the output was increased by 5%, and coal was saved by 3 %, after one year of operation, there is no contamination and slagging problem, which improves the operating safety of the unit.

Embodiment 3

[0028] Example 3 A nanocomposite material and nanocomposite furnace tube

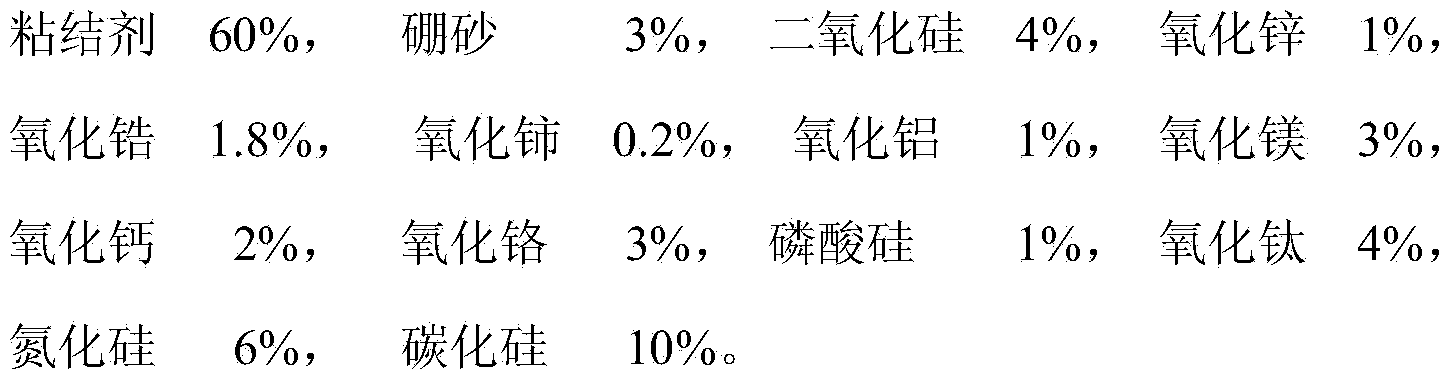

[0029] (1) Composition of nanocomposites

[0030]

[0031] In this embodiment, the adhesive is styrene-acrylic emulsion, and water glass, water-soluble acrylic resin or water-soluble silicone resin can also be used.

[0032] (2) Nano composite furnace tube

[0033] The preparation method is as follows: with embodiment 1.

[0034] (3) Effect experiment

[0035] The steam injection furnace of a special oil station in PetroChina, the unit with ordinary furnace tubes, has serious coking, increased thermal resistance, and decreased. After adopting the nanocomposite material furnace tube of the present invention, the furnace temperature is 1000 ° C, the output is increased, and the coal saving rate is 8.3%. , After 2 years of operation, no coking problem occurs, saving a lot of fuel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com