Thin film used for hole sealing of porous interconnection dielectric surface and preparing method of thin film

A dielectric surface and thin film technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problem of the decrease in the adhesion of the cap layer, the increase in the effective dielectric constant of the interconnect dielectric layer, the mechanical properties and electrical properties. problems such as drop, to achieve the effects of excellent uniformity, excellent mechanical properties, and excellent insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

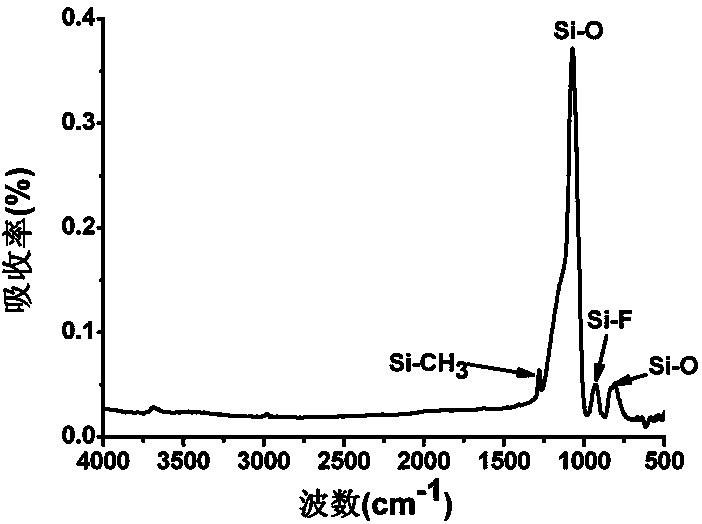

[0025] 1. Put a wafer covered with a low dielectric constant (k) porous interconnection medium on a tray in the reaction chamber of a plasma-enhanced chemical vapor deposition (PECVD) device. The porous material is a porous SiCOH film, or Porous SiO 2 film. Close the cavity, and then evacuate the cavity to 0.02-0.03 torr.

[0026] 2. Raise the temperature of the substrate to 200-400 °C, and then inject He gas to preheat the gas pipeline to prevent the incompletely vaporized liquid source from condensing on the tube wall.

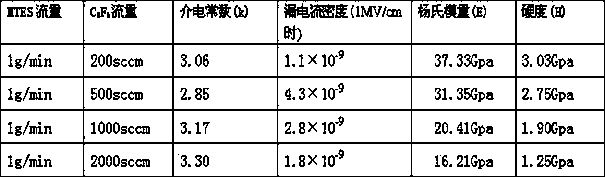

[0027] 3. Through the control of LFM, MTES is fed into the vaporizer at a fixed flow rate of 1g / min, and the vaporized MTES is loaded into the reaction chamber through He gas, and the flow rate of the carrier gas He is 5000 sccm.

[0028] 4. Another reaction gas C 2 f 6 It is controlled directly into the reaction chamber by a mass flow meter (MFC), and its flow rate is 200-2000 sccm.

[0029] 5. In the reaction chamber, C 2 f 6 Mix with vaporized MTES...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com