Technology for producing metallized furnace charge from iron-containing dust and high-silicon iron concentrate

A high-silicon ferrosilicon and metallization technology, which is applied in the field of iron and steel metallurgy, can solve the problems of complex equipment process, high production cost, and large amount of dust to be processed, and achieve the effects of simple process flow, energy saving, and rational use of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

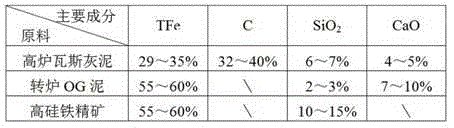

[0024] (1) Mixing of materials: Blast furnace gas mortar with a water content of 8%, converter OG mud, high-silicon iron concentrate and bentonite are mixed in a weight ratio of 100:20:70:2 and stirred evenly to make become a mixed material.

[0025] Moisturizing, briquetting and drying of materials: transport the mixed material into the hopper of the briquetting machine, and wet the mixed material by spraying water, and at the same time, the material is pressed into briquettes by the mechanical force of the briquetting machine, and qualified briquettes are obtained from Take it out of the briquetting machine. The size of the briquette is controlled to be 53×115×230mm, and the moisture content is controlled at 5-7%. Qualified briquettes are sent to the drying kiln for drying. The heat source of the drying kiln is the flue gas at 200-400 °C discharged from the tunnel kiln. The drying time is controlled at 5 hours, and the flow rate of the flue gas in the drying kiln is control...

Embodiment 2

[0030] (1) Mixing of materials: Blast furnace gas mortar with a water content of 6%, converter OG mud, high silicon iron concentrate and bentonite are mixed according to a weight ratio of 100:30:60:2 and stirred evenly to make become a mixed material.

[0031] Moisturizing, briquetting and drying of materials: transport the mixed material into the hopper of the briquetting machine, and wet the mixed material by spraying water, and at the same time, the material is pressed into briquettes by the mechanical force of the briquetting machine, and qualified briquettes are obtained from Take it out of the briquetting machine. The size of the compact is controlled to be 53×115×230mm, and the moisture content is 5%. Qualified briquettes are sent to the drying kiln for drying. The heat source of the drying kiln is the flue gas at 200-400 °C discharged from the tunnel kiln. The drying time is controlled at 4 hours, and the flow rate of the flue gas in the drying kiln is controlled at 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com