Process for recycling chinlon from waste chinlon blended fabric and recycled product

A technology of blended fabrics and nylon, which is applied in the field of IPCD01G11/00, can solve the problems of inability to be recycled, low recovery rate of target textiles, difficulty in balancing fabric recovery rate and environmental protection of operation, and achieve high value-added utilization, dissolution Strong, low boiling point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a kind of technology that reclaims nylon from waste nylon blended fabric, comprises the following steps:

[0041] S1. Using an organic extractant to extract the waste nylon blended fabric to obtain an extract;

[0042] S2. reduce the temperature of the extract, and collect the precipitated solid during the cooling process;

[0043] S3. Purifying the collected solid to obtain a recycled nylon product.

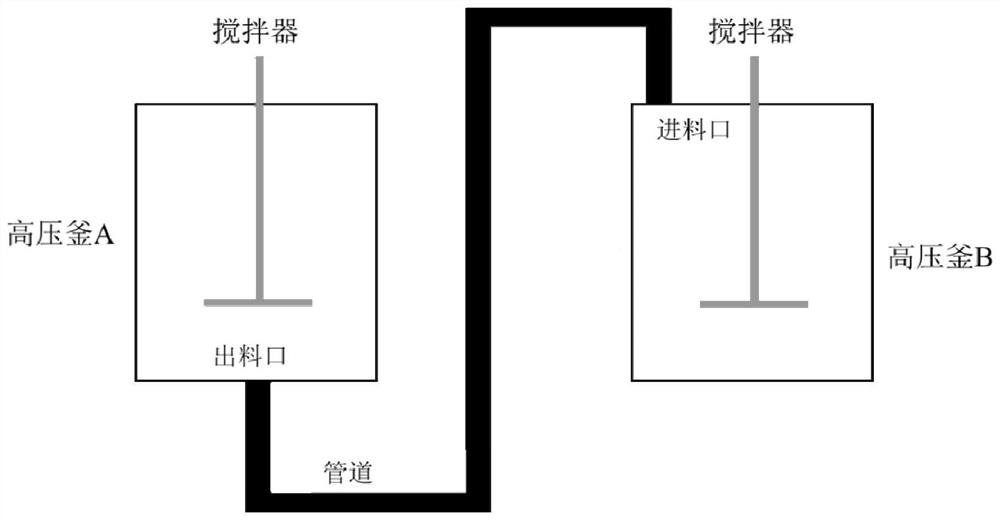

[0044] The S1 step is specifically to pretreat the waste nylon blended fabric, then transfer it to the autoclave A, add an organic extractant to the autoclave A, seal the autoclave A, and act at an extraction temperature of 135°C for 20-120min After the extraction is completed, an extract is obtained; at the same time, a non-nylon recovery product is obtained.

[0045] The pretreatment operation is to dry the waste nylon blended fabric at 80° C. for 6 hours.

[0046] The S2 step specifically includes transferring the extract to the autoclave B,...

Embodiment 2

[0057] This embodiment provides a process for recycling nylon from waste nylon blended fabrics. The specific implementation method is the same as in Example 1; the difference is that the waste nylon blended fabrics are polyester / spandex waste white cloth; The weight ratio of fiber and spandex fiber is 95:5.

Embodiment 3

[0059] This embodiment provides a process for recycling nylon from waste nylon blended fabrics. The specific implementation method is the same as in Example 1; the difference is that the waste nylon blended fabrics are polyester / cotton waste white cloth; The weight ratio of fiber and cotton fiber is 65:35.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com