Imnetic algae strain Chlorella sorokiniana HN01 and application thereof

A CCTCCM2013608, microalgae technology, applied in the direction of single-cell algae, microorganisms, biochemical equipment and methods, etc., can solve problems such as difficult large-scale high-density cultivation, high energy consumption costs in the treatment process, water source pollution, etc., to ensure high density High-quality fermentation and the effect of enhancing international competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Prepare 500mL of BG-11 medium, and insert it into the microalgae seed liquid that has been expanded and cultivated according to the inoculation amount of 15v / v%. The initial pH is 4.0, the temperature is 28°C, the light-dark ratio is 12:12 (day: night), the light intensity is 15000lux, the amount of glucose added is 2g / L, and the sterile air of 0.2vvm is passed through, and cultivated for 14 days.

[0061] The algal cells were collected by centrifugation, dried in a vacuum freeze dryer, and the algal powder was weighed and the dry weight was calculated. The biomass concentration of algae powder is 700mg / L, the biomass yield is 50mg / L / d, and the oil content determined by the chloroform-methanol method is 22%. The protein content is more than 40%, and the linoleic acid and linolenic acid account for more than 40% of the total fatty acid composition. The HPLC spectrum of the fatty acid methyl ester composition is as follows Figure 4 shown.

[0062] Example 2

Embodiment 2

[0064] Prepare 500mL of BG-11 medium, and insert it into the expanded cell culture medium according to the inoculation amount of 5v / v%. The initial pH is 8.0, the temperature is 28°C, the light-dark ratio is 12:12 (day: night), the light intensity is 7500lux, the amount of glucose added is 15g / L, and the sterile air of 0.33vvm (CO2 content is 0.03% (v / v) ), cultivated for 9 days.

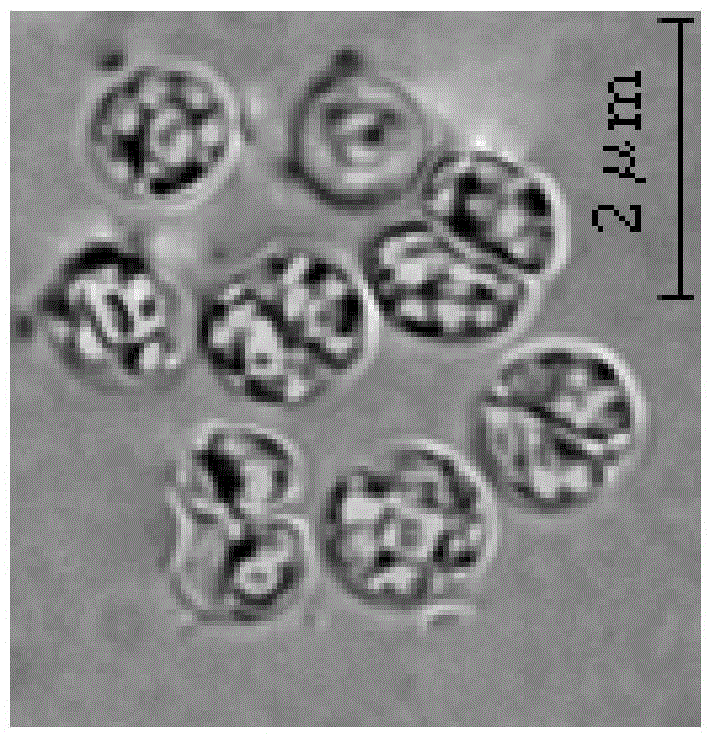

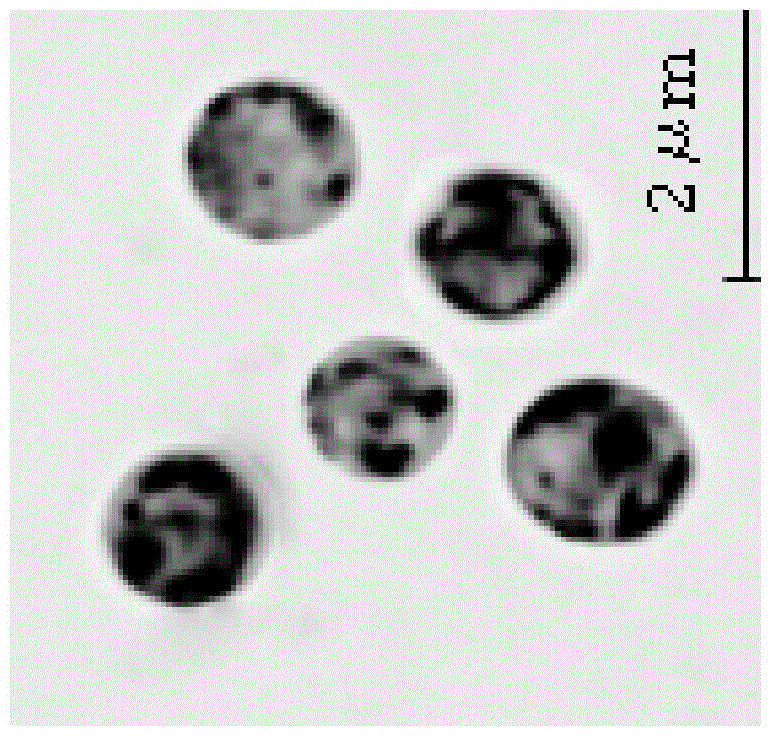

[0065] The algal cells were collected by centrifugation, dried in a vacuum freeze dryer, and the algal powder was weighed and the dry weight was calculated. The biomass concentration of algal powder was 6.2g / L, the biomass yield was 0.67g / L / d, and the oil content was 43% as determined by the chloroform-methanol method. The protein content is more than 38%, and linoleic acid and linolenic acid account for more than 20% of the total fatty acid composition. The scanning electron microscope photos, optical microscope photos, and fat droplet staining photos of microalgae cells are shown in Figure 1-3 ...

Embodiment 3

[0068] Prepare 500mL of BG-11 medium, and insert the expanded microalgae cells. The initial pH is 11.0, the temperature is 45°C, the light-to-dark ratio is 12:12 (day:night), the light intensity is 2500lux, the amount of glucose added is 15g / L, and the sterile air of 0.33vvm (CO2 content is 0.03% (v / v) ), cultured for 5 days.

[0069] The algal cells were collected by centrifugation, dried in a vacuum freeze dryer, and the algal powder was weighed and the dry weight was calculated. The biomass concentration of algae powder was 4.4g / L, the biomass yield was 0.49g / L / d, and the oil content was 31% as determined by the chloroform-methanol method. The protein content is more than 40%, and the linoleic acid and linolenic acid account for more than 20% of the total fatty acid composition.

[0070] Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com