A kind of wood-plastic composite material and preparation method thereof

A wood-plastic composite material and thermoplastic technology, which is applied in the field of packaging materials, can solve the problems of poor moisture resistance, poor mechanical properties, and non-compliance with the application requirements of ammunition packaging box materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

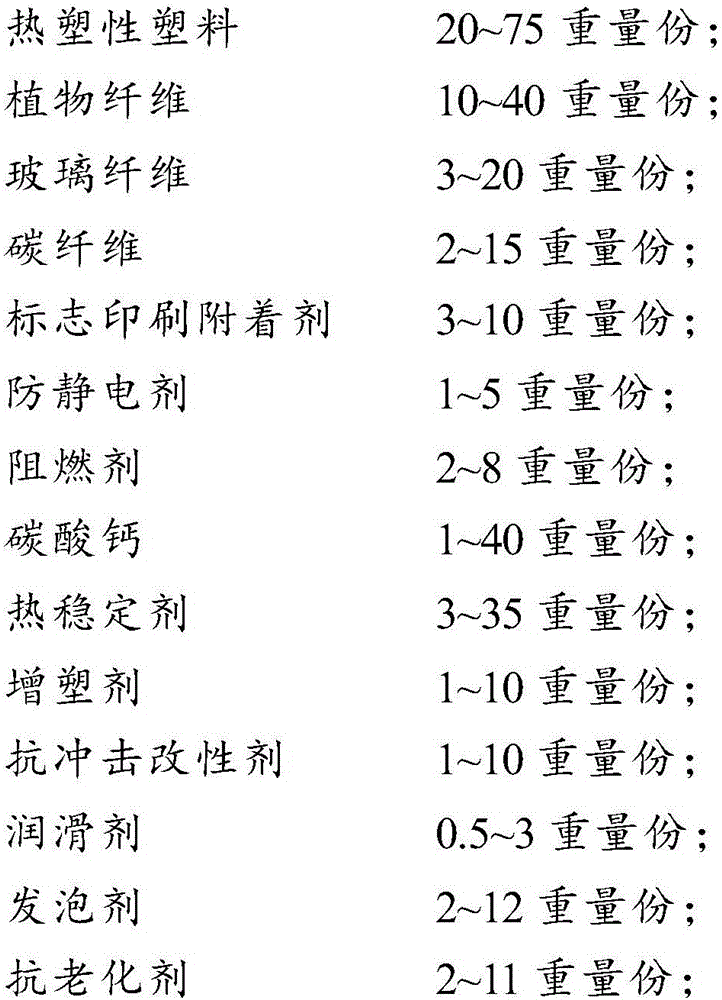

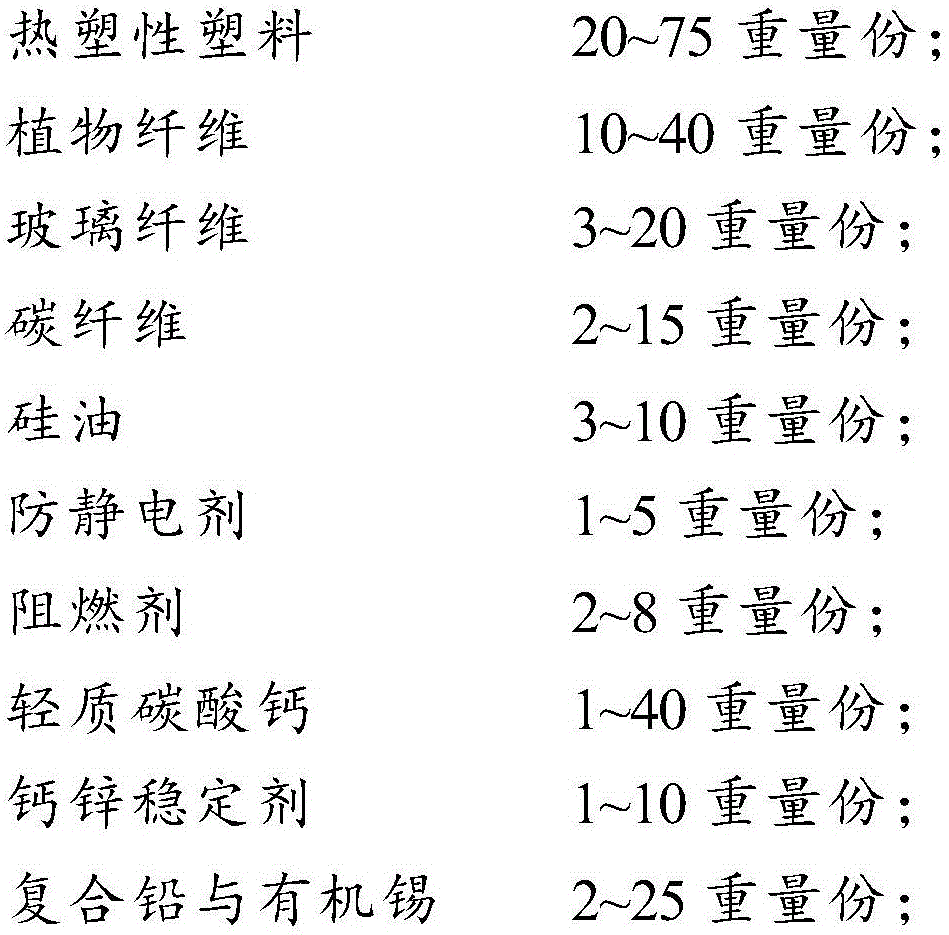

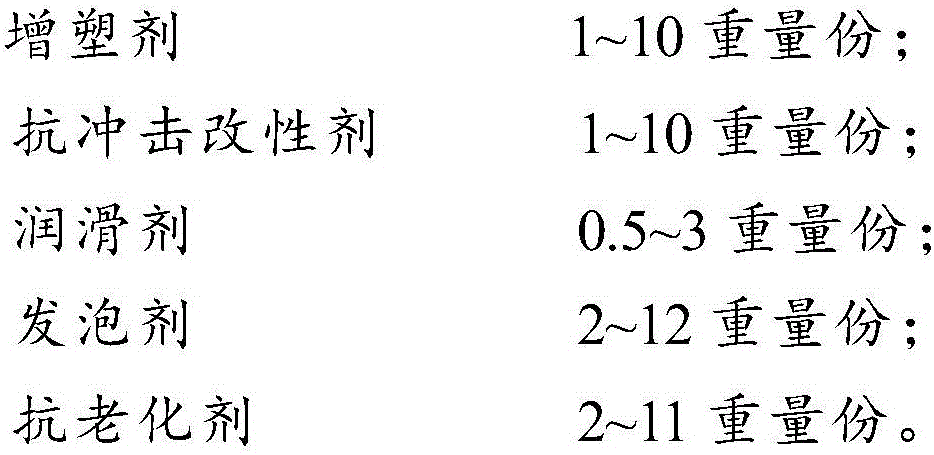

[0083] The present invention also provides a method for preparing the above wood-plastic composite material, comprising: mixing 20-75 parts by weight of thermoplastic, 10-40 parts by weight of plant fibers, 3-20 parts by weight of glass fibers, and 2-15 parts by weight of glass fibers. carbon fiber, 3-10 parts by weight of sign printing adhesive, 1-5 parts by weight of antistatic agent, 2-8 parts by weight of flame retardant, 10-40 parts by weight of calcium carbonate, 3-35 parts by weight of heat Stabilizer, 1-10 parts by weight of plasticizer, 2-12 parts by weight of foaming agent, 1-10 parts by weight of impact modifier, 0.5-3 parts by weight of lubricant and 2-11 parts by weight of The aging agent is mixed, heated and melted, and extruded to obtain a wood-plastic composite material.

[0084] Wherein, the raw materials are the same as above, and will not be repeated here.

[0085] The temperature of the heating and melting is preferably 90°C to 150°C, and more preferably 1...

Embodiment 1

[0092] 1.1 46 parts by weight of polyvinyl chloride, 19 parts by weight of bamboo fiber and wood fiber, 5 parts by weight of glass fiber, 3 parts by weight of carbon fiber, 2 parts by weight of antistatic agent (the mass ratio of copper, zinc and aluminum is 3:2:1), 3 parts by weight of antimony trioxide, 4 parts by weight of silicone oil, 3 parts by weight of light calcium carbonate, 1 part by weight of calcium zinc stabilizer, 2 parts by weight of composite lead and organotin ( The mass ratio of the two is 1:2), 2 parts by weight of epoxidized soybean oil, 2 parts by weight of chlorinated polyethylene, 2 parts by weight of azobisisobutyronitrile, 1 part by weight of zinc stearate, 1 part by weight of Parts of sodium benzoate, 2 parts by weight of UV powder and 2 parts by weight of titanium dioxide and phthalocyanine green were added to a high-speed mixer and mixed, heated to 120 ° C, mixed at a high temperature for 5 minutes, then cooled to 40 ° C, extruded to obtain extrusio...

Embodiment 2

[0099] 2.1 34 parts by weight of polyvinyl chloride, 13 parts by weight of bamboo fiber and wood fiber, 11 parts by weight of glass fiber, 8 parts by weight of carbon fiber, 1 part by weight of antistatic agent (the mass ratio of copper, zinc and aluminum is 3:2:1), 2 parts by weight of decabromodiphenylethane, 3 parts by weight of silicone oil, 10 parts by weight of light calcium carbonate, 1 part by weight of calcium zinc stabilizer, 3 parts by weight of composite lead and organic Tin (the mass ratio of the two is 1:2), 1 part by weight of epoxidized soybean oil, 1 part by weight of chlorinated polyethylene, 4 parts by weight of azobisisobutyronitrile, 1 part by weight of calcium stearate, 2 parts by weight of sodium benzoate, 3 parts by weight of UV powder and 2 parts by weight of titanium dioxide and phthalocyanine green are added into a high-speed mixer and mixed, heated to 120 ° C, mixed at high temperature for 5 minutes, then cooled to 40 ° C, extruded to obtain extruda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com