Flame-retardant adhesive tape capable of being used for wrapping lithium ion battery and preparation method of flame-retardant adhesive tape

A technology for lithium-ion batteries and flame-retardant tapes, which is applied in sustainable manufacturing/processing, adhesives, and final product manufacturing, and can solve problems such as lithium-ion batteries spontaneously igniting, poor printability, and high haze of tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

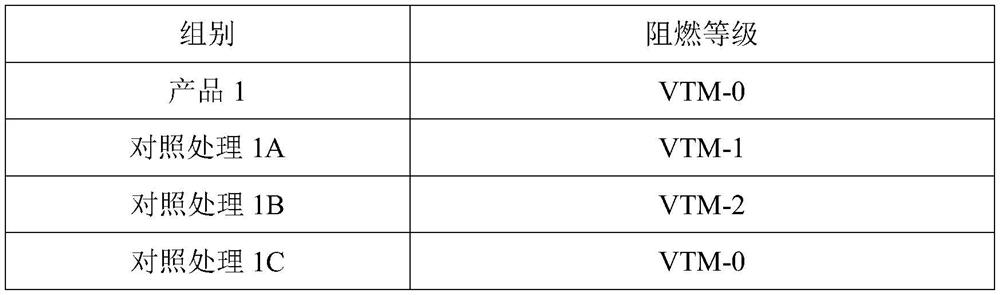

Examples

Embodiment 1

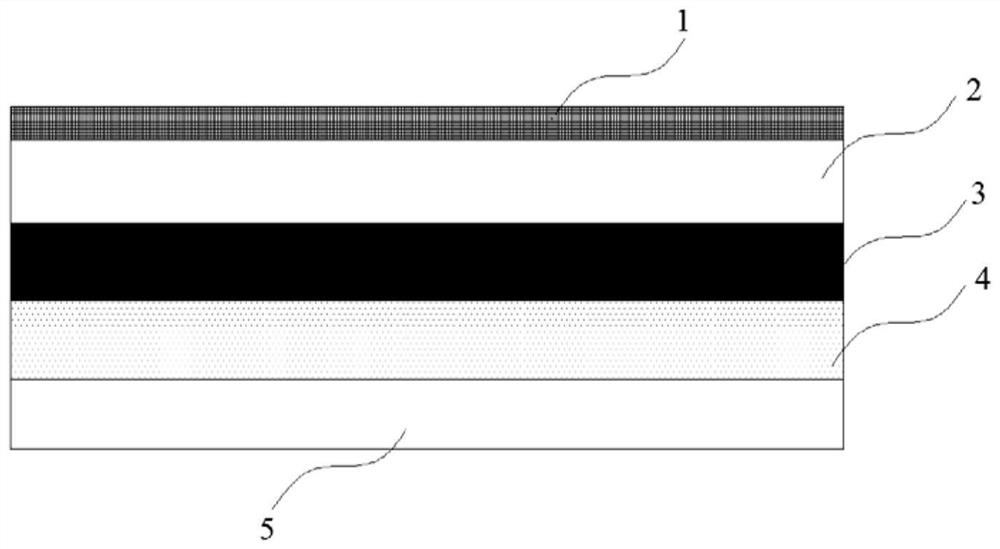

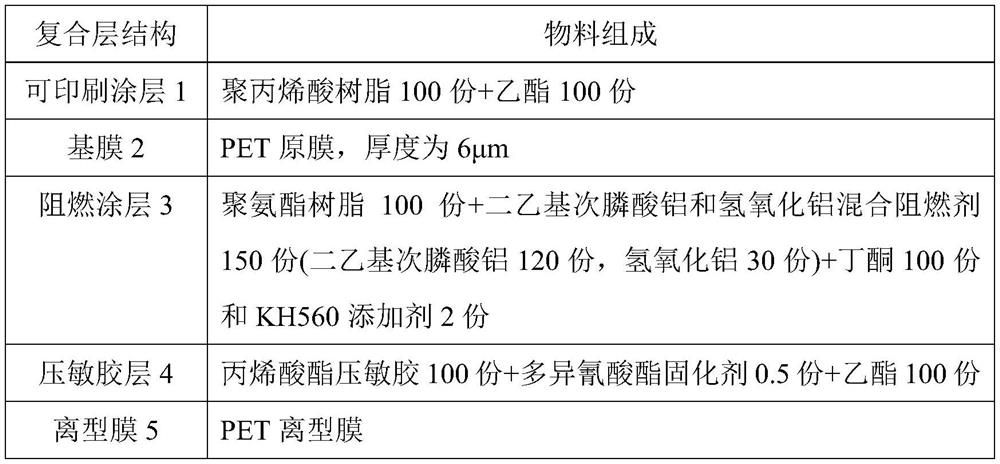

[0024] The materials used to prepare the composite layers of the flame-retardant adhesive tape in this example are shown in Table 1. According to Table 1, the required materials were weighed, and the slurries for coating and preparing the composite layers were prepared respectively.

[0025] Table 1 The raw material composition of each composite layer in the flame-retardant adhesive tape of this embodiment

[0026]

[0027] Prepare the flame retardant adhesive tape of this implementation according to the following steps:

[0028] Step 1: the base film 2 includes two sides facing away from each other, and the material for preparing the printable coating 1 is applied to one side of the base film 2 by using a coating machine to form a printable coating 1, by The thickness of the formed printable coating 1 is about 1 μm;

[0029] Step 2: Use a coating machine to coat the material used to prepare the flame-retardant coating 3 on the other side of the base film 2 to form a flame...

Embodiment 2

[0038] The materials used to prepare the composite layers of the flame-retardant adhesive tape in this embodiment are shown in Table 3. The required materials were weighed according to Table 3, and the slurries for coating and preparing the composite layers were prepared respectively.

[0039] Table 3 The raw material composition of each composite layer in the flame-retardant adhesive tape of this embodiment

[0040]

[0041] Prepare the flame retardant adhesive tape of this implementation according to the following steps:

[0042] Step 1: the base film 2 includes two sides facing away from each other, and the material for preparing the printable coating 1 is applied to one side of the base film 2 by using a coating machine to form a printable coating 1, by The thickness of the formed printable coating 1 is about 1 μm;

[0043] Step 2: Use a coating machine to coat the material used to prepare the flame-retardant coating 3 on the other side of the base film 2 to form a fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com