In-situ upgraded treatment method for realizing zero discharge of refinery and chemical wastewater and biological stuffing used in in-situ upgraded treatment method

A technology for in-situ upgrading and refining sewage, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of reducing the treatment effect of oil refining sewage below 5mg/L Difficulty in showing, gathering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The modified polyurethane fluidized filler in Comparative Example 1 was replaced with the activated carbon modified polypropylene cylindrical hollow three-dimensional filler of the present invention. Activated carbon (specific surface area 1300m 2 / g, particle size 300-400 mesh) accounts for 3% of the mass percentage of polypropylene, and 0.1% of 1-3mm acrylic fiber is added. The filler after molding is a hollow cylindrical structure with two layers inside and outside, and the diameter of the inner cylinder is 1.2 cm, the diameter of the outer cylinder is 2.5cm, the inner and outer cylinders are connected by 8 edges, and the density of the hollow cylindrical filler is 0.98g / cm 3 , the specific surface area is about 800m 2 / m 3 . Place the hollow three-dimensional filler in a rectangular stainless steel mesh cage with a specification of 950mm×1400mm×2500mm. The mesh of the stainless steel mesh cage is 1cm×1cm, and the filler dosage accounts for 30% of the cage volume....

Embodiment 2

[0087] The three-dimensional hollow filler cage in embodiment 1 is changed into alternately discharged hollow filler cage and modified polyurethane filler cage (polyurethane foam filler, hollow filler are respectively identical with aforementioned comparative example 2 and embodiment 1), that is, each The biochemical pool discharges fillers in the following order: modified polyurethane filler cage - three-dimensional hollow filler cage - modified polyurethane filler cage - three-dimensional hollow filler cage. The packing amount of each mesh cage is 30% of the mesh cage volume, and the size and specifications of the mesh cage and other operating parameters etc. are all the same as in Example 1.

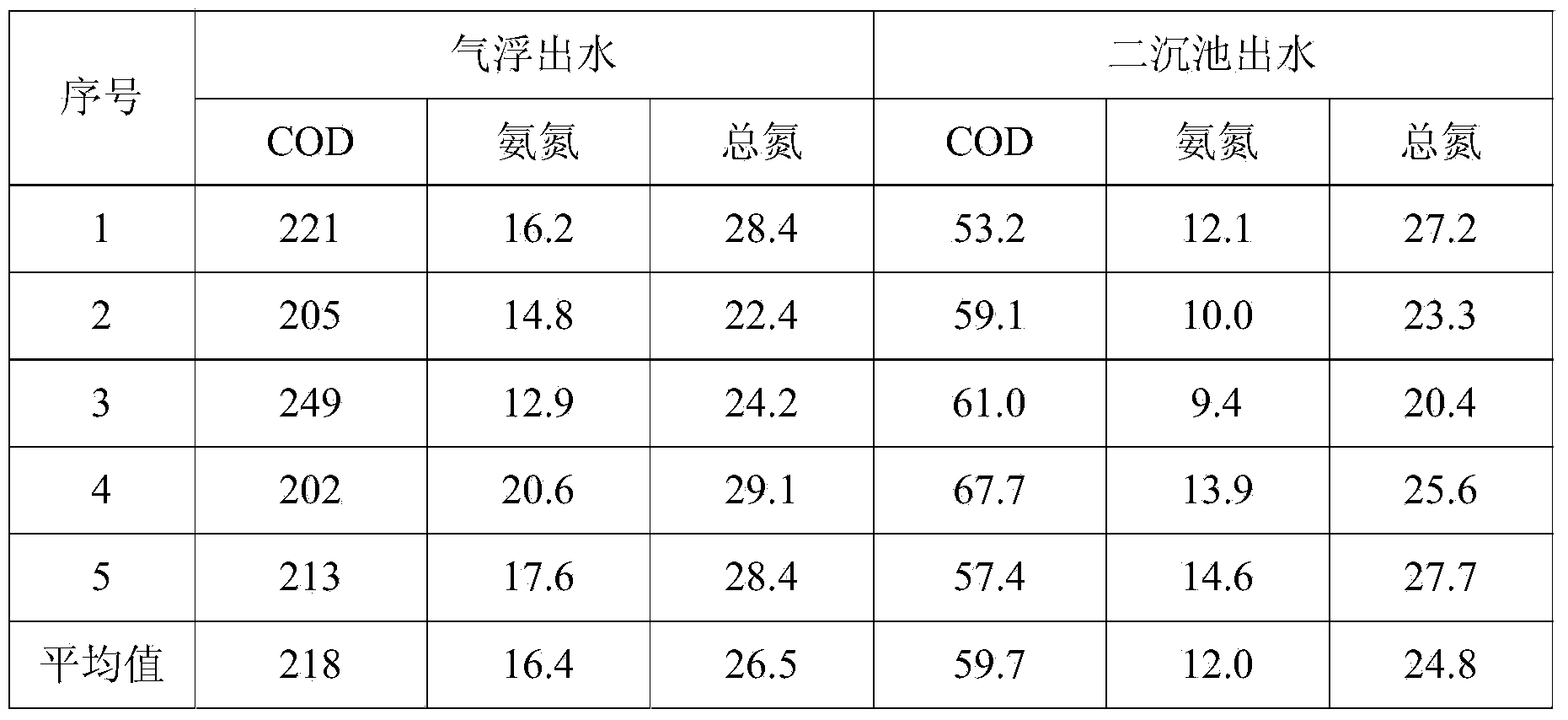

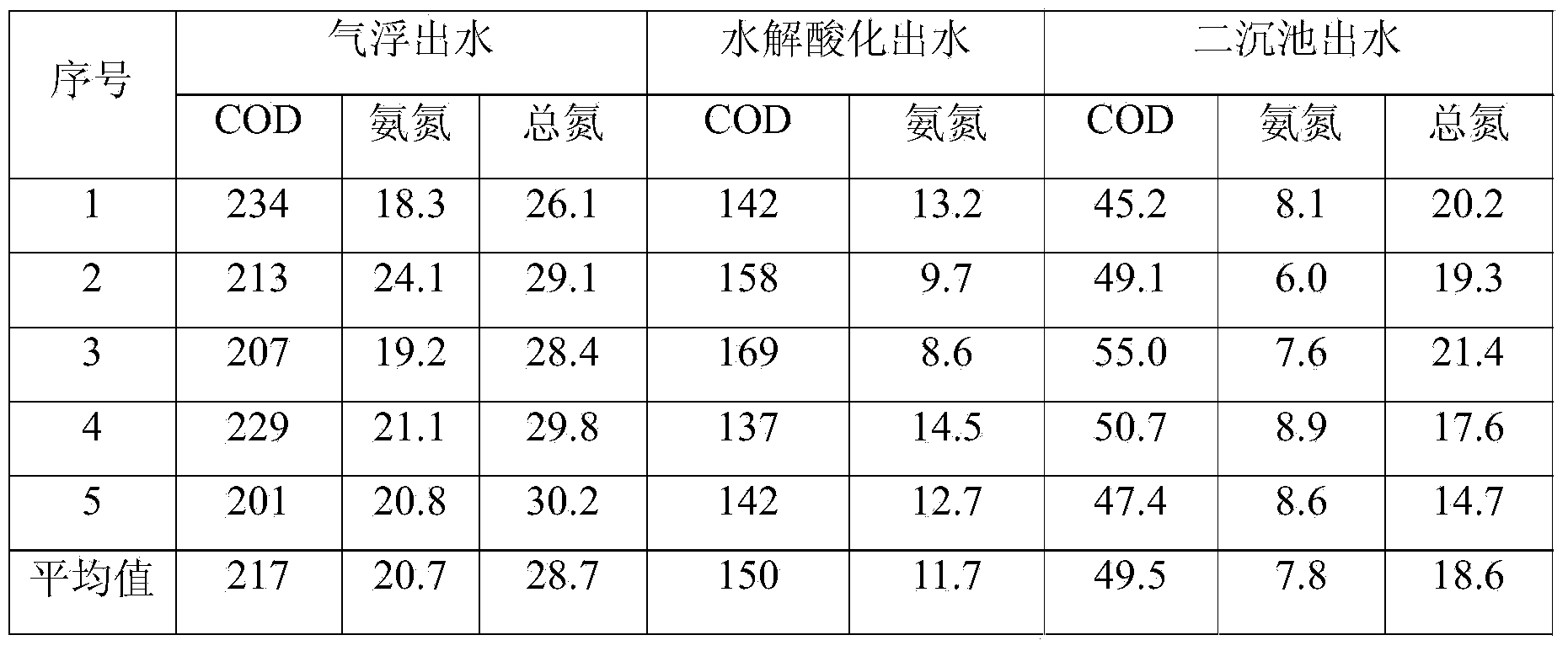

[0088] After stable operation, the effluent water quality indicators of each process section are shown in Table 4. It can be seen that after adopting the above two kinds of modified biological fillers and uniform fluidized distribution of fillers, the COD, ammonia nitrogen and total n...

Embodiment 3

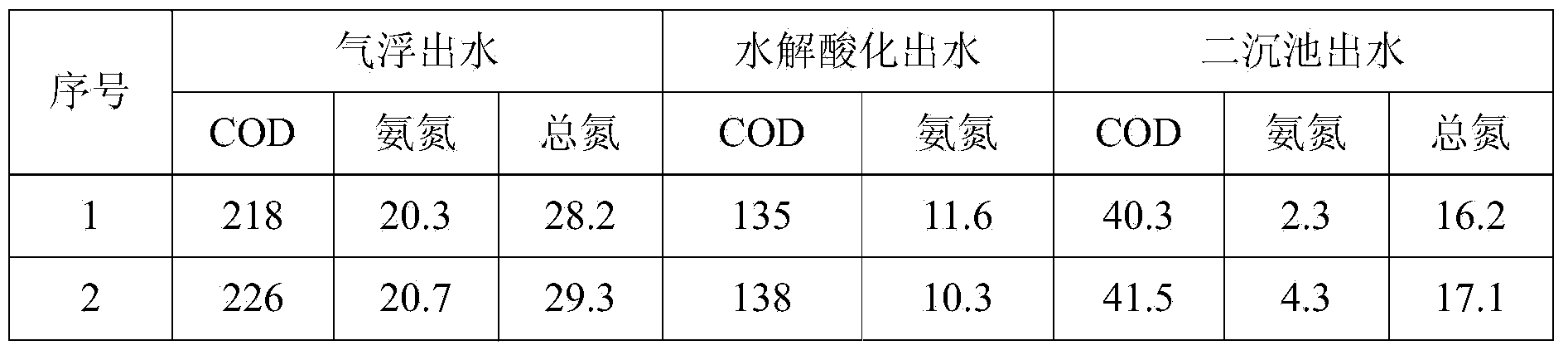

[0092] The fillers of the filler cages in Example 2 are increased by 10%, that is, the filler dosage is about 40% of the water volume of the biochemical tank, the reflux ratio of the mixed liquid in the aeration tank is 200%, and the sludge reflux ratio is 40%. Other conditions and implementation The same as Example 2, the effluent water quality indicators of each process section after stable operation are shown in Table 5. It can be seen that after the filler is increased from 30% to 40%, the control of effluent COD and ammonia nitrogen is further improved, but the effect is not obvious.

[0093] Table 5 Concentration of pollutants in each stage of in-situ upgrading treatment process of oil refinery wastewater (mg / L)

[0094]

[0095] Through the above method for treating oil refining sewage of the present invention, without changing the original structure of the sewage treatment plant, by changing the operating process, and adopting the modified biological filler of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com