A thermocouple protection sleeve and its manufacturing method

A technology of protective sleeve and manufacturing method, which is applied in the direction of thermometers that are directly sensitive to heat/magnetic elements, measuring heat, and using electrical devices, etc., which can solve the problems of affecting normal process operation, increasing maintenance costs, and high corundum brittleness, etc. problems, to achieve the effect of improving service life, reducing maintenance costs, and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

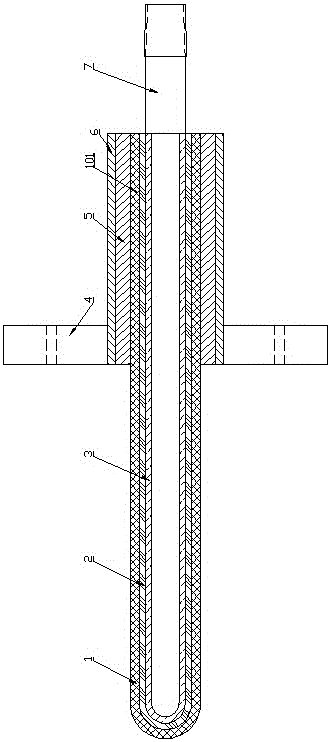

[0023] like figure 1 As shown, the thermocouple protection sleeve includes a white steel inner sleeve 3 with one end closed and a corundum outer sleeve 1, the corundum outer sleeve 1 is set on the white steel inner sleeve 3, the white steel inner sleeve 3 and the corundum outer sleeve 1 A titanium dioxide bonding layer 2 is filled between the outer casing 1, and the connecting section 101 at the rear of the corundum outer casing 1 is wound with an asbestos rope 5 and bonded with a connecting pipe 6, and the connecting section 101 of the corundum outer casing 1 is connected to the connecting pipe 6 have the same length, and the length is 100 mm to 150 mm. In this embodiment, the length is 100 mm as an example. The material of the connecting pipe 6 is white steel; the front end of the connecting pipe 6 is welded with a connecting flange 4, and the white steel The opening end of the inner casing 3 is welded with a wire head 7, the wall thickness of the white steel inner casing 3 ...

Embodiment 2

[0031] The structure of this thermocouple protection sleeve is with embodiment 1;

[0032] Its specific production steps are as follows:

[0033] (1), titanium dioxide and sodium silicate (Na 2 O nSiO 2 ) aqueous solution according to the mass-volume ratio of 2:1g / mL was mixed and stirred evenly to obtain a paste of titanium dioxide, and the concentration of the aqueous solution of sodium silicate was 210g / L;

[0034] (2) Take a corundum outer sleeve 1 and a white steel inner sleeve 3 that are the same length as the thermocouple core and have one end closed. The gap between the corundum outer sleeve 1 and the white steel inner sleeve 3 after insertion is 2mm. Pour the prepared titanium dioxide paste into the corundum outer sleeve 1 and fill it up to ensure that the air in the corundum outer sleeve 1 is completely discharged;

[0035] (3) After dipping the asbestos rope 5 in the titanium dioxide paste, wind the asbestos rope 5 dipped in the titanium dioxide paste on the conn...

Embodiment 3

[0039] The structure of this thermocouple protection sleeve is with embodiment 1;

[0040] Its specific production steps are as follows:

[0041] (1), titanium dioxide and sodium silicate (Na 2 O nSiO 2 ) aqueous solution according to the mass-volume ratio of 2:1g / mL was mixed and stirred evenly to obtain a paste of titanium dioxide, and the concentration of the aqueous solution of sodium silicate was 230 g / L;

[0042] (2) Take a corundum outer sleeve 1 and a white steel inner sleeve 3 that are the same length as the thermocouple core and have one end closed. The gap between the corundum outer sleeve 1 and the white steel inner sleeve 3 after insertion is 3mm. Pour the prepared titanium dioxide paste into the corundum outer sleeve 1 and fill it up to ensure that the air in the corundum outer sleeve 1 is completely discharged;

[0043](3) After dipping the asbestos rope 5 in the titanium dioxide paste, wind the asbestos rope 5 dipped in the titanium dioxide paste on the conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com