Low-rank coal purification power generation system

A power generation system and low-rank coal technology, applied in the direction of machines/engines, combustion methods, lighting and heating equipment, etc., can solve the problems of large discharge volume of flue gas tail, high processing cost, low use efficiency, etc., and achieve safety and economy problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

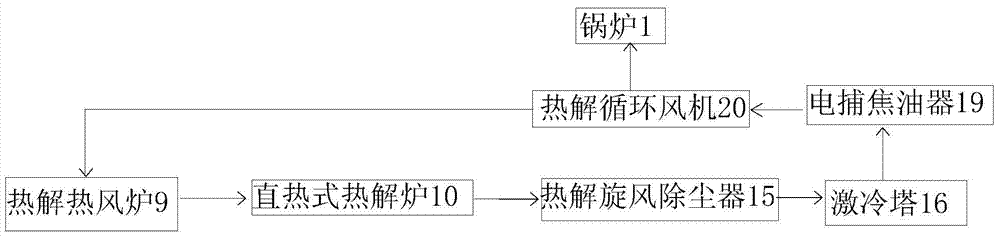

[0033] see Figure 1-Figure 2 , respectively are the schematic diagram of the low-rank coal purification power generation system and the low-rank coal drying and purification schematic diagram of the present invention. As shown in the figure, the medium and low-rank coal purification power generation system of the present invention includes a boiler 1 for burning fuel, a steam turbine 28 for power generation, and a power plant condenser 24 that can condense steam into water, wherein the steam exhaust port of the boiler 1 Connect the air inlet of the steam turbine 28, the exhaust port of the steam turbine 28 is connected to the air inlet of the condenser 24 of the power plant, and the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com