Water-soluble compound corrosion inhibitor

A technology of water-soluble compound and corrosion inhibitor, which is applied in the direction of corrosion prevention during distillation, can solve the problems of affecting film formation and neutralization, and cannot achieve the comprehensive effect of anti-corrosion of the tower top system, and achieves strong corrosion resistance , strong neutralization ability and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

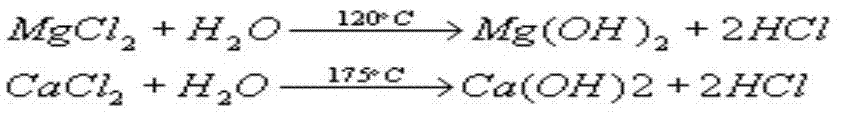

Problems solved by technology

Method used

Image

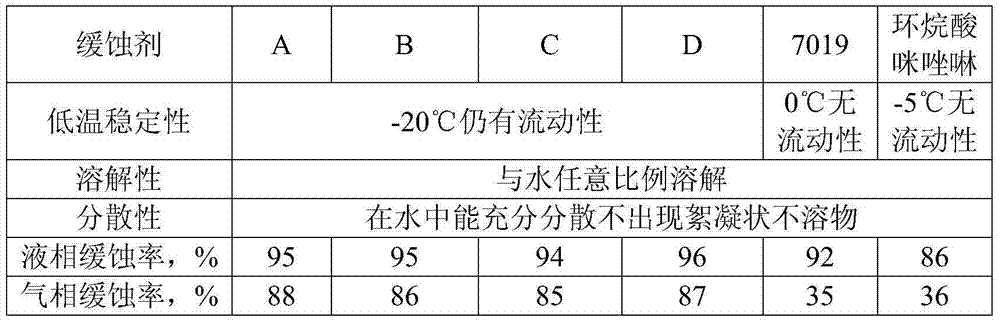

Examples

Embodiment 1

[0025] First add 140g of 3,5-lutidine quaternary ammonium salt into a three-necked flask, then add 100g of tolyltriazole, 180g of morpholine, and 180g of solvent (deionized water) in sequence, and stir at room temperature and pressure After 30 minutes, filter out impurities to obtain composite corrosion inhibitor A.

Embodiment 2

[0027] First add 120g of 2,3,5-lutidine quaternary ammonium salt into a three-necked flask, then add 80g of tolyltriazole, 180g of monoethanolamine, and 180g of solvent (propylene glycol) in sequence, and stir at room temperature and pressure After 30 minutes, filter out impurities to obtain composite corrosion inhibitor B.

Embodiment 3

[0029] First add 140g of 3,5-lutidine quaternary ammonium salt into the three-necked flask, then add 100g of 5-methylbenzotriazole, 160g of monoethanolamine, and 200g of solvent (deionized water: propylene glycol = 1:1), Stir at room temperature and pressure for 30 minutes, then filter to remove impurities to obtain composite corrosion inhibitor C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com