Method for preparing cadmium sulfide quantum dots

A technology of quantum dots and cadmium sulfide, which is applied in the field of semiconductor nanomaterial preparation, can solve the problems of strong toxicity, high risk and aging of organic cadmium, and achieves good monodispersity and stability, wide adjustable spectrum range and fast reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] First, a cadmium oleate solution is prepared. Take 0.3mmol (0.0384g) of cadmium oxide powder, 0.61mmol (0.213mL) of oleic acid, and 3.787mL of octadecene, heat to 250°C under nitrogen protection until the cadmium oxide powder dissolves, cool to 80°C, and prepare Into cadmium oleate solution, which is light yellow transparent solution.

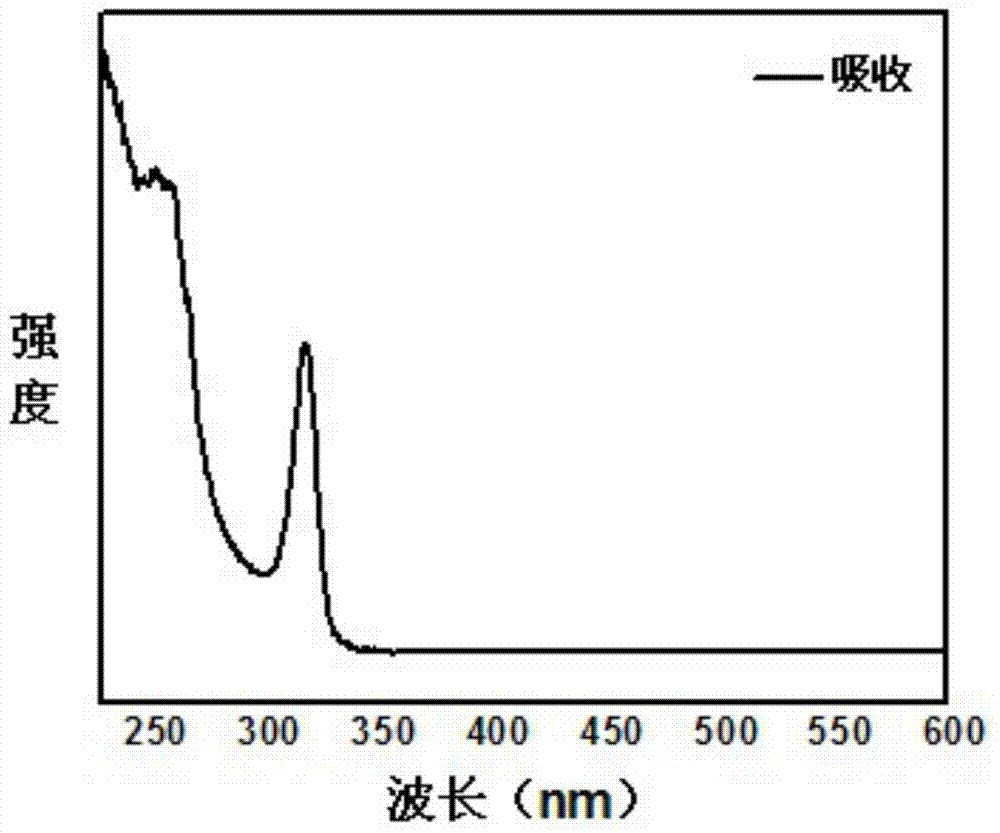

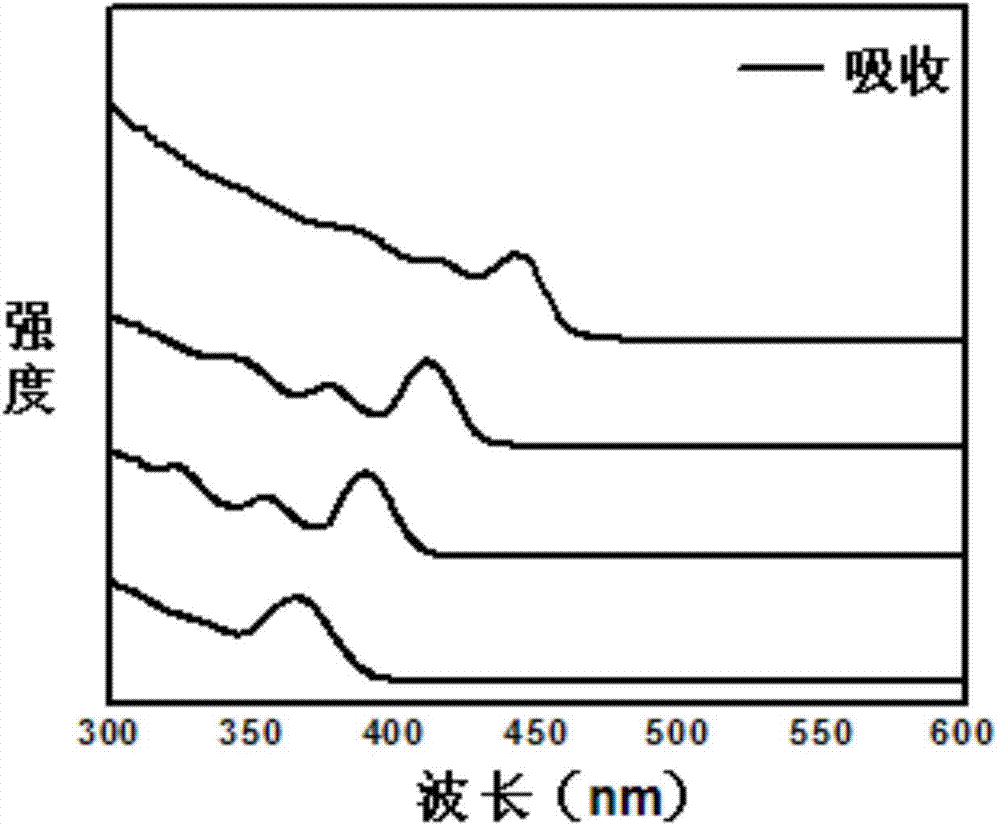

[0027] Then take 0.5mL concentration of 0.1 mol / L (TMS) 2 The octadecene solution of S was injected into the above-mentioned cadmium oleate solution at 80° C., and reacted for 5 minutes to obtain CdS nanoclusters. Its UV-visible absorption peaks are sharp and symmetrical, showing a good size distribution.

Embodiment 2

[0029] First, a cadmium myristate solution is prepared. Take 10mmol (1.28g) of cadmium oxide powder, 21mmol (4.79g) of myristic acid, and 15mL of octadecene, heat to 250°C under nitrogen protection, and cool to 120°C to prepare a cadmium myristate solution. It is a colorless transparent solution.

[0030] Then take 2 mL of (TMS) with a concentration of 0.5 mol / L 2 The octadecene solution of S was injected into the above-mentioned cadmium myristate solution at 120° C., and reacted for 5 minutes to obtain CdS nanoclusters. The concentration of the product increased slightly, but the UV-visible absorption peaks remained sharp and symmetrical.

Embodiment 3

[0032] First, a cadmium myristate solution is prepared. Get 80mmol (10.24g) of cadmium oxide powder, 170mmol (38.82g) of myristic acid, and 130mL of octadecene, heat to 250°C under nitrogen protection conditions, cool to 100°C, and prepare a cadmium myristate solution. It is a colorless transparent solution.

[0033] Then take 10 mL of (TMS) with a concentration of 1 mol / L 2 The octadecene solution of S was injected into the above-mentioned cadmium myristate solution at 100° C., and reacted for 10 minutes to obtain CdS nanoclusters. After increasing the concentration, the UV-visible absorption peaks remained sharp and symmetrical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com