Silicon wafer phosphorus and aluminum combined temperature varying and impurity suction method for preparing solar cells

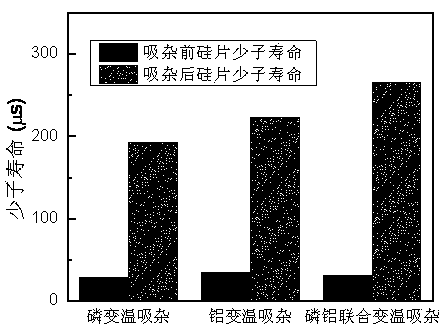

A silicon wafer phosphor-aluminum, solar cell technology, applied in circuits, photovoltaic power generation, electrical components and other directions, can solve the problems of long process cycle, weak gettering effect, affecting the gettering effect, etc., and achieves obvious gettering effect and minority carrier life. Improve and satisfy the effect of gettering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A silicon wafer phosphorus-aluminum temperature-variable gettering method for preparing solar cells, comprising the following steps:

[0023] 1) De-damage layer: Prepare a NaOH solution with a concentration of 10wt%, and use a water bath to heat the solution at a constant temperature of 80°C. Put the monocrystalline silicon wafer into the solution for 8 minutes to remove the silicon damage caused by the wire saw cutting the silicon wafer. layer, take out the monocrystalline silicon wafer and wash it with deionized water for 3 minutes;

[0024] 2) Cleaning: Put the above-mentioned single crystal silicon wafer with the damaged layer into the acetone solution at 25°C for ultrasonic cleaning for 5 minutes, take it out and clean it with deionized water for 3 minutes, and then put the sample in absolute ethanol at 25°C for ultrasonic cleaning 5min, take it out, wash it with deionized water for 3min, and blow it dry with nitrogen for later use;

[0025] 3) Coating phosphorus ...

Embodiment 2

[0032] A silicon wafer phosphorus-aluminum temperature-variable gettering method for preparing solar cells, comprising the following steps:

[0033] 1) De-damage layer: Prepare a NaOH solution with a concentration of 15wt%, keep the solution at a constant temperature of 80°C by heating in a water bath, and put the monocrystalline silicon wafer into the solution for 10 minutes to remove the silicon damage caused by wire saw cutting the silicon wafer layer, take out the monocrystalline silicon wafer and wash it with deionized water for 3 minutes;

[0034] 2) Cleaning: Put the above-mentioned single crystal silicon wafer with the damaged layer into the acetone solution at 25°C for ultrasonic cleaning for 5 minutes, take it out and clean it with deionized water for 3 minutes, and then put the sample in absolute ethanol at 25°C for ultrasonic cleaning 5min, take it out, wash it with deionized water for 3min, and blow it dry with nitrogen for later use;

Embodiment 3

[0042]A silicon wafer phosphorus-aluminum temperature-variable gettering method for preparing solar cells, comprising the following steps:

[0043] 1) Remove the damaged layer: Prepare a NaOH solution with a concentration of 10wt%, and use a water bath to heat the solution at a constant temperature of 80°C. Put the polysilicon wafer in the solution for 15 minutes to remove the silicon damaged layer caused by the wire saw cutting the silicon wafer. After taking out the polysilicon wafer, wash it with deionized water for 3 minutes;

[0044] 2) Cleaning: Put the polysilicon wafer with the above-mentioned damaged layer into the acetone solution at 25°C for ultrasonic cleaning for 5 minutes, take it out and wash it with deionized water for 3 minutes, and then put the sample in absolute ethanol at 25°C for ultrasonic cleaning for 5 minutes. After taking it out, wash it with deionized water for 3 minutes, and dry it with nitrogen gas for later use;

[0045] 3) Coating phosphorus sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com