High-temperature resistant radio-frequency cable

A radio frequency cable, high temperature resistant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor chemical resistance, unsatisfactory use, and weak firmness, etc., to reduce weight, enhance firmness, and increase flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

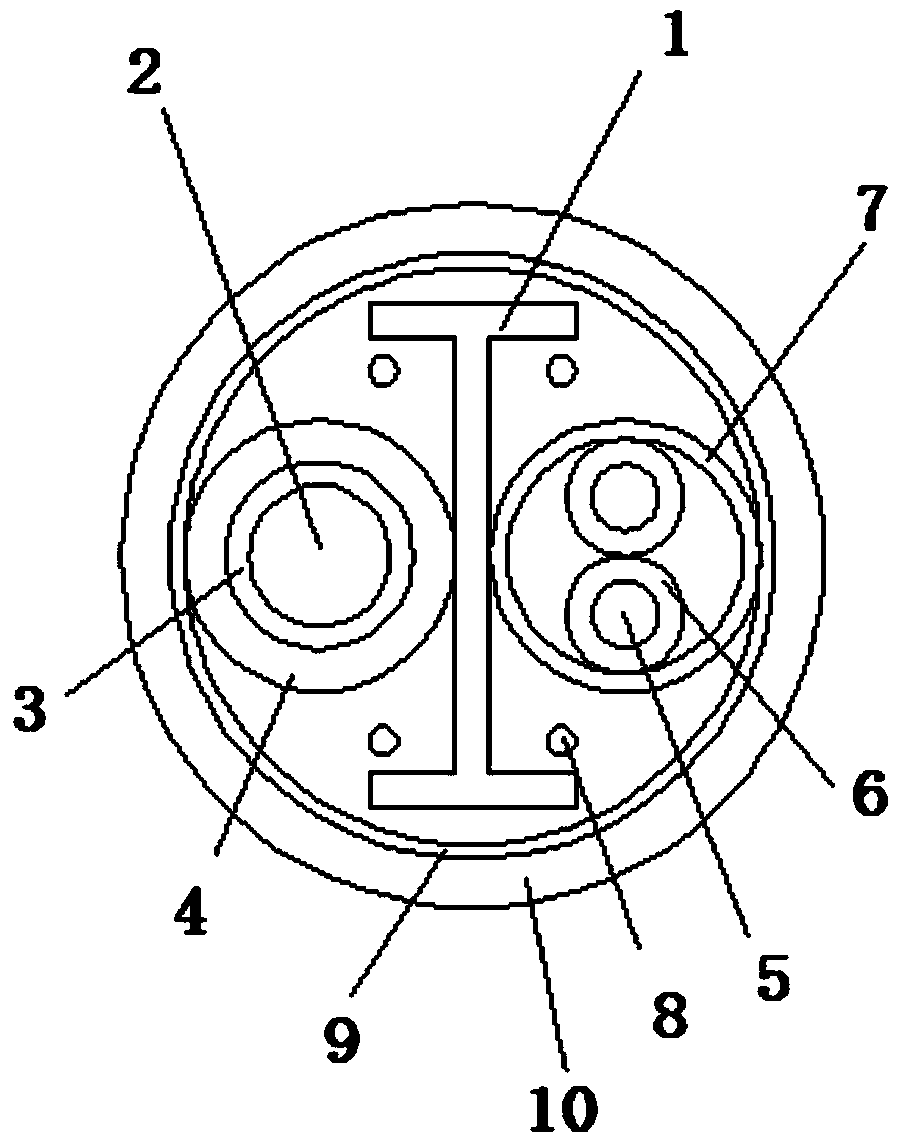

[0016] Such as figure 1 As shown, the high temperature resistant radio frequency cable includes an I-shaped nylon frame 1, a main core is provided on the left side of the nylon frame 1, a control core is provided on the right side of the nylon frame 1, and a main core includes a thermoplastic Elastomer 3, the main conductor 2 of the copper wire braided shielding layer 4, the control wire core includes two control conductors 5 wrapped with a silicone rubber insulating layer 6, and the outer side of the two control conductors 5 is twisted and wrapped with a copper tape braided shielding layer 7. The main wire core, the control wire core, the nylon skeleton 1 and several tensile steel wires 8 are twisted to form a cable core, and the cable core is wrapped with an aluminum alloy wire braided armor layer 9 and a sheath layer 10 in sequence. The material of the sheath layer 10 is made of the following raw materials in parts by weight: linear low density polyethylene 60, tetrafluoroe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com