Preparation method of carbon fiber surface antioxidation coating

An anti-oxidation coating and carbon fiber technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of uneven coating, exhaust gas polluting the air, high processing temperature, etc., and achieve simple process, easy raw materials, and curing temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

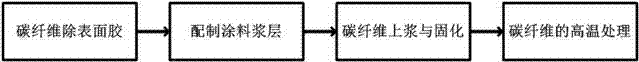

Method used

Image

Examples

Embodiment 1

[0023] In the first step, using acetone as a solvent, the carbon fiber is processed by Soxhlet extraction method to remove the glue layer and other attachments on the surface of the carbon fiber bundle 6;

[0024] In the second step, take 1 part of silane coupling agent A151 as a precursor in parts by weight, join 98 parts of hydroalcoholic solutions composed of 75wt% ethanol and 25wt% distilled water to form a mixed solution, then add glacial acetic acid to make the mixed solution Adjust the pH value to 0.1-0.3, stir thoroughly for 60 minutes, then add 5 parts of silicon carbide powder as reinforcing particles, and stir thoroughly for 60 minutes to form a coating slurry;

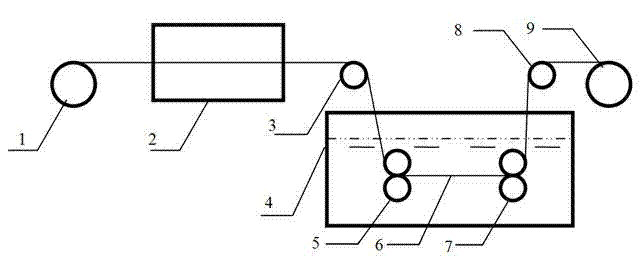

[0025] In the third step, the coating slurry is injected into the dipping tank 4, and the carbon fiber bundle 6 after the degumming is arranged on the pay-off wheel 9 above the dipping tank 4, and then passes through the introduction wheel 8 and is arranged in the dipping tank 4 successively. The second pai...

Embodiment 2

[0028]The first step is to use ethanol as a solvent to treat the carbon fiber cloth through the Soxhlet extraction method to remove the adhesive layer and other attachments on the surface of the carbon fiber cloth;

[0029] In the second step, 2 parts of silane coupling agent K570 are taken as a precursor, and added to 100 parts of a hydroalcoholic solution composed of 95wt% ethanol and 5wt% distilled water to form a mixed solution, then adding glacial acetic acid to adjust the pH value of the mixed solution to 0.1-0.3, fully stirred for 80 minutes, then added 4 parts of boron nitride powder as reinforcing particles, fully stirred for 80 minutes to form a coating slurry;

[0030] The third step is to inject the coating slurry into the dipping tank, put the degummed carbon fiber cloth into the dipping tank, and then ultrasonically treat it for 30 minutes, so that the slurry is fully immersed in the carbon fiber cloth; take it out, and use a glass rod on the surface of the carbon...

Embodiment 3

[0033] In the first step, using chloroform as a solvent, the three-dimensional woven carbon fiber prefabricated body is treated by Soxhlet extraction method, and the glue layer and other attachments on the surface of the three-dimensional woven carbon fiber prefabricated body are removed;

[0034] In the second step, take 2 parts of silane coupling agent K550 as a precursor, add it to 95 parts of a hydroalcoholic solution composed of 95wt% isopropanol and 5wt% distilled water to form a mixed solution, stir thoroughly for 50 minutes, and then add 6 parts of silicon carbide The powder is used as reinforcing particles, and stirred for another 50 minutes to form a coating slurry;

[0035] The third step is to inject the coating slurry into the dipping tank, put the three-dimensional braided carbon fiber prefabricated body after degumming into the dipping tank, and then ultrasonically treat it for 30 minutes, so that the slurry is fully immersed in the three-dimensional braided carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com