A kind of tapered array flexible electrode and preparation method thereof

A flexible electrode and tapered technology, applied in the field of biomedical engineering, can solve the problems of easy disconnection of the conductive layer, shedding, and affecting the efficiency of electrode stimulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A tapered array flexible electrode comprises a flexible polymer substrate and a metal conductive layer attached to the substrate. The material of the flexible polymer base is polyethylene terephthalate, and the surface of one side of the flexible polymer base has a nano-conical array structure, the height of the cone is 560nm, the diameter of the bottom is 290nm, and the outer circumference of the cone is The surface is a rough surface, the material of the metal conductive layer is gold, and the thickness of the metal conductive layer is 180nm.

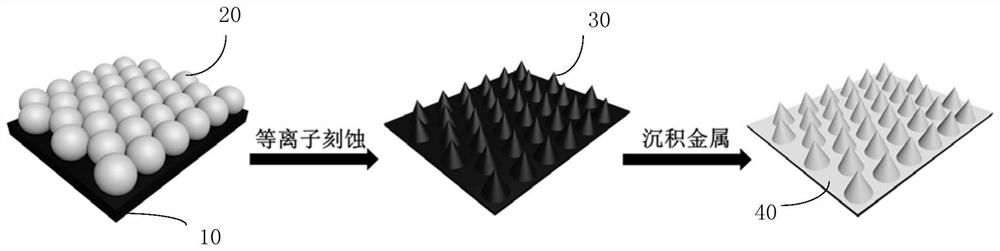

[0052] Such as figure 1 Shown, the preparation method of this tapered array flexible electrode comprises the following steps:

[0053] (1) Take the polyethylene terephthalate flexible substrate 10, clean its surface to remove surface dust and impurities, and dry it with nitrogen gas for later use;

[0054] (2) Carry out oxygen plasma treatment to the surface of polyethylene terephthalate 10 to make its surface hydrophilic, an...

Embodiment 2

[0058] The difference between the tapered array flexible electrode of this embodiment 2 and the embodiment 1 is that the tapered height of the nano tapered array structure on the surface of the flexible polymer substrate is 600nm, the bottom diameter is 240nm, and the thickness of the metal conductive layer is 55nm.

[0059] The preparation method of the conical array flexible electrode of this embodiment is basically the same as that of Embodiment 1, the only difference is that this embodiment uses polystyrene microspheres with a diameter of 1 μm as a template, and the specific parameters of plasma etching and magnetron sputtering The process parameters of injection are different.

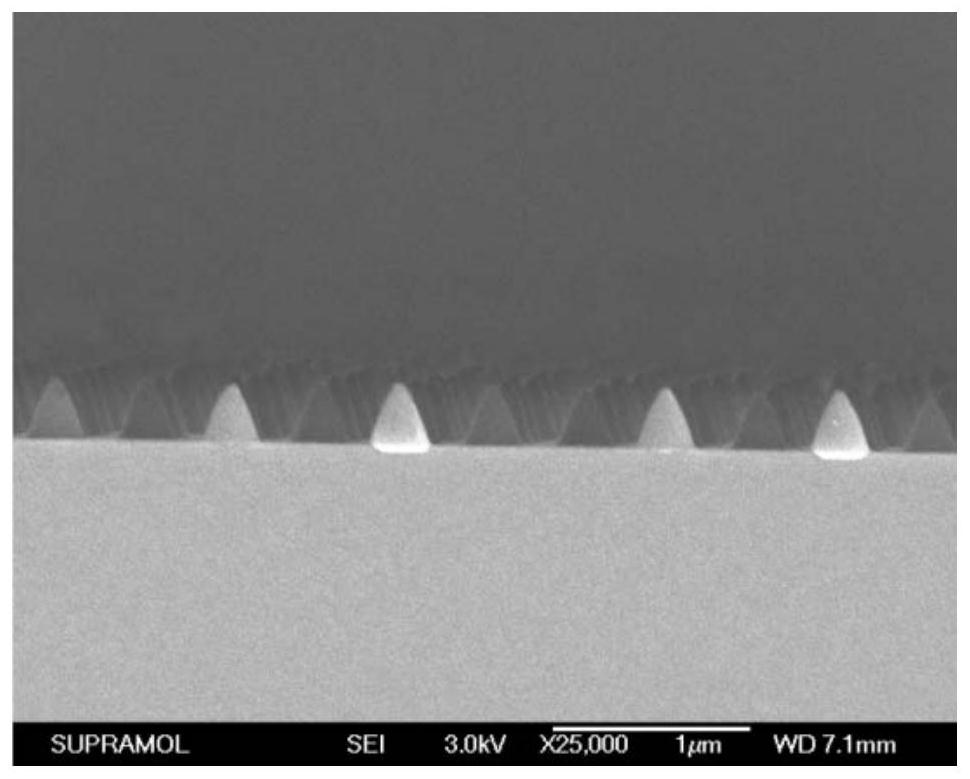

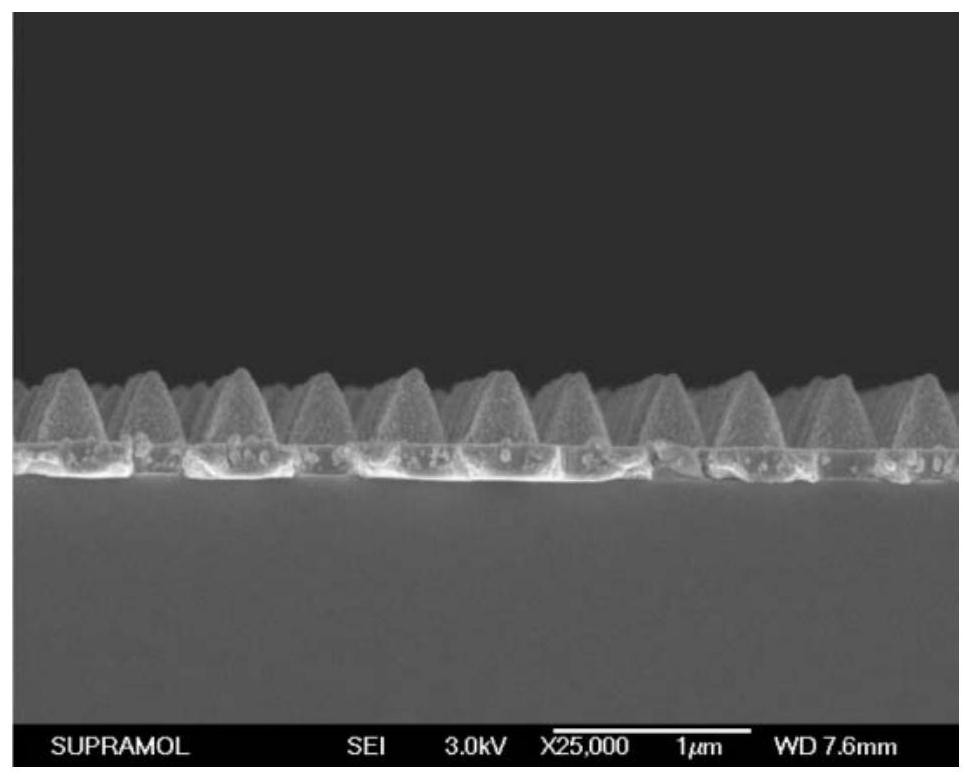

[0060] The electron microscope image of the nano-conical array structure on the surface of the flexible polymer substrate prepared in this example is as follows Figure 3a As shown, the electron microscope image of the final tapered array flexible electrode is as follows Figure 3b shown.

Embodiment 3

[0062] A tapered array flexible electrode comprises a flexible polymer substrate and a metal conductive layer attached to the substrate. The material of the flexible polymer base is polyethylene terephthalate, and the surface of one side of the flexible polymer base has a nano-conical array structure, the height of the cone is 690nm, the diameter of the bottom is 380nm, and the outer circumference of the cone is The surface is a rough surface, the material of the metal conductive layer is platinum, and the thickness of the metal conductive layer is 160nm.

[0063] The preparation method of the tapered array flexible electrode in this example is basically the same as that in Example 1, the only difference is that this example uses polystyrene microspheres with a diameter of 1 μm as a template, and the target material for sputtering to prepare a metal conductive layer is a platinum target materials, and the specific parameters of plasma etching are different from those of magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com