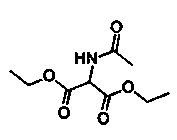

Method for preparing intermediate diethyl acetamidomalonate through organic synthesis

A technology for producing diethyl acetamidomalonate and diethyl oximinomalonate is applied in the field of preparation of important organic synthesis intermediate diethyl acetamidomalonate, achieving low cost, high product purity, The effect of little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment one: a kind of preparation method of organic synthesis intermediate acetamidomalonate diethyl ester

[0020] In a 500 mL four-necked flask equipped with a thermometer, add 69 g of water, 80 g of diethyl malonate, 69 g of sodium nitrite, and 0.3 g of tetrabutylammonium bromide as a phase transfer catalyst. 58.3 ml of acetic acid was added dropwise, and the dropwise addition was completed in about 1 h. After the dropwise addition was completed, the reaction was carried out at 30-40 °C for 4 h. Add 50 ml of water and 300 ml of dichloromethane for extraction, combine the organic phases, add anhydrous sodium sulfate and dry overnight. The precipitate was filtered off, and the filtrate was added to a 1000ml four-neck flask.

[0021] A condenser tube was added to a 1000ml four-necked flask, and the solvent was distilled off under reduced pressure. Then add 130kg of acetic anhydride, 300ml of glacial acetic acid, and slowly add 110g of zinc powder at room temperat...

Embodiment 2

[0022] Embodiment 2: a kind of preparation method of organic synthesis intermediate acetamidomalonate diethyl ester

[0023] In the enamel reaction kettle of 1000L equipped with tail gas absorption system, add water 200kg, open stirring, add diethyl malonate 160kg, sodium nitrite 140kg, phase transfer catalyst tetrabutylammonium bromide 1kg successively, cool to 5 ℃, 120L of acetic acid was added dropwise, and the dropwise addition was completed in about 3h. After the dropwise addition, the reaction was carried out at 35~40°C for 4h. Add 60kg of water and dichloromethane to extract twice, each time 300L of dichloroethane, the organic phases are combined and dried with anhydrous sodium sulfate for 6 hours.

[0024] After drying, the filtration was completed, and the filtrate was added to a 2000L enamel reaction kettle, and the solvent was distilled off under reduced pressure. Then add 260kg of acetic anhydride, 600kg of acetic acid, and slowly add 220kg of zinc powder at norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com