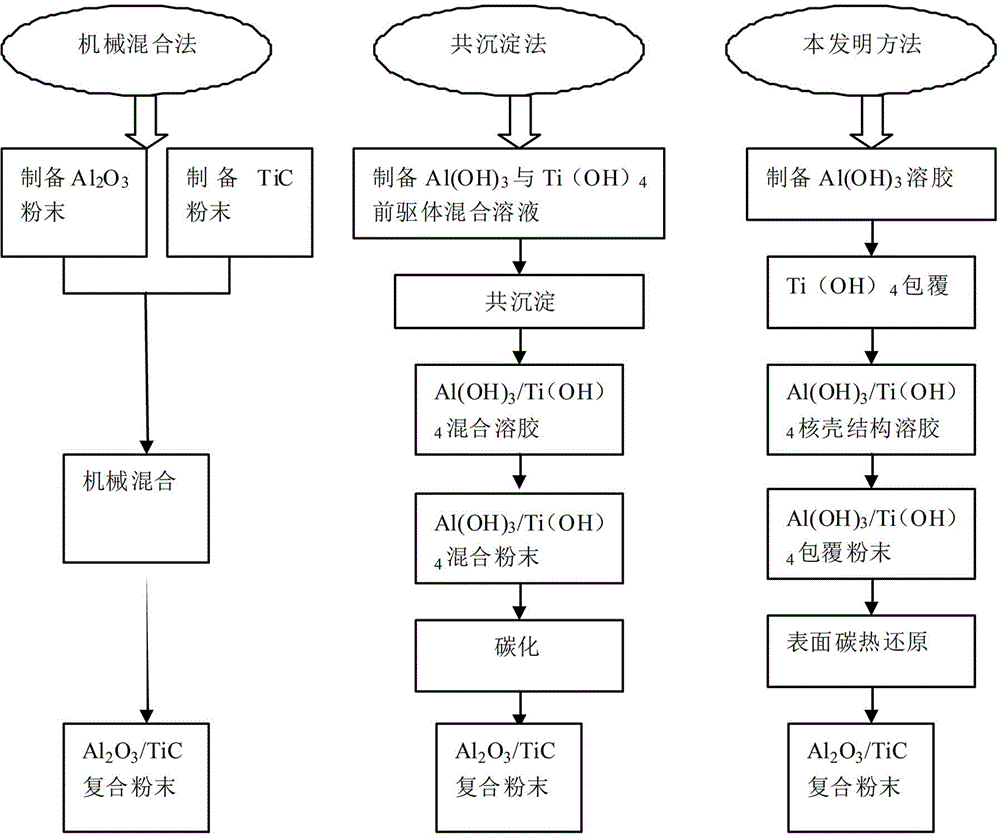

Alumina/titanium carbide composite powder preparation method

A technology of composite powder and coated powder, which is applied in the field of powder metallurgy, can solve the problems of complex process and unfavorable TiC modification effect, and achieve the effect of simple preparation process and controllable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Example 1: First, put C 9 h 21 AlO 3 Add it into deionized water to make a solution with a volume percentage concentration of 0.6%, add ammonia water to adjust the pH value of the solution to 8.5, stir at 28°C for 1.5h with a magnetic stirrer at a stirring speed of 35r / min, and then place it for 4h to form Al(OH) 3 Sol. Then, the TiCl 4 Add Al(OH) 3 sol, make TiCl 4 The volume concentration is 0.15%, which is equivalent to C9 h 21 AlO 3 The volume concentration percentage is 25%, add ammonia water to adjust the pH value of the solution to 8.5, stir with a magnetic stirrer at 70°C for 2h, the stirring speed is 20r / min, and then leave it for 5h, the generated Ti(OH) 4 in Al(OH) 3 Surface coating forms Al(OH) 3 / Ti(OH) 4 Core / shell structure sol. C used 9 h 21 AlO 3 、TiCl 4 and ammonia were of analytical grade. Al(OH) 3 / Ti(OH) 4 The core / shell structure sol was dried in a vacuum drying oven at a drying temperature of 110 °C, a heating rate of 5 °C / min, ...

example 2

[0019] Example 2: First, put C 9 h 21 AlO 3 Add it into deionized water to make a solution with a concentration of 1.7% by volume, add ammonia water to adjust the pH value of the solution to 8, stir with a magnetic stirrer at 25°C for 2h at a stirring speed of 30r / min, and then place it for 3h to form Al (OH) 3 Sol. Then, the TiCl 4 Add Al(OH) 3 sol, make TiCl 4 The volume concentration is 0.68%, which is equivalent to C 9 h 21 AlO 3 The volume concentration percentage is 40%, add ammonia water to adjust the pH value of the solution to 9, stir with a magnetic stirrer at 70°C for 3h, the stirring speed is 40r / min, and then leave it for 6h, the generated Ti(OH) 4 in Al(OH) 3 Surface coating forms Al(OH) 3 / Ti(OH) 4 Core / shell structure sol. C used 9 h 21 AlO 3 、TiCl 4 and ammonia were of analytical grade. Al(OH) 3 / Ti(OH) 4 The core / shell structure sol was dried in a vacuum drying oven at a drying temperature of 95 °C, a heating rate of 6 °C / min, a holding ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com