Sample preparation method for electron back scattering diffraction analysis of thin steel and iron material

A technology of electron backscattering and iron and steel materials, which is applied in the field of sample preparation for EBSD analysis of thin-gauge steel and iron materials, and achieves the effects of simple and fast operation, high observation effect, high quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The thin-gauge steel material used in the examples is 0.5 mm bainitic steel, and the equipment used for electron backscatter diffraction analysis is a FEI Quanta400 scanning electron microscope equipped with an Oxford EBSD accessory.

[0031] A sample preparation method for electron backscattered diffraction analysis of thin-gauge iron and steel materials, comprising the steps of:

[0032] (1) Use a precision cutting machine to cut bainite steel into small pieces with a plate size of 1.5cm×1.5cm as a sample, and use sandpaper to grind one side of the sample plate surface. The grinding plane is the B side;

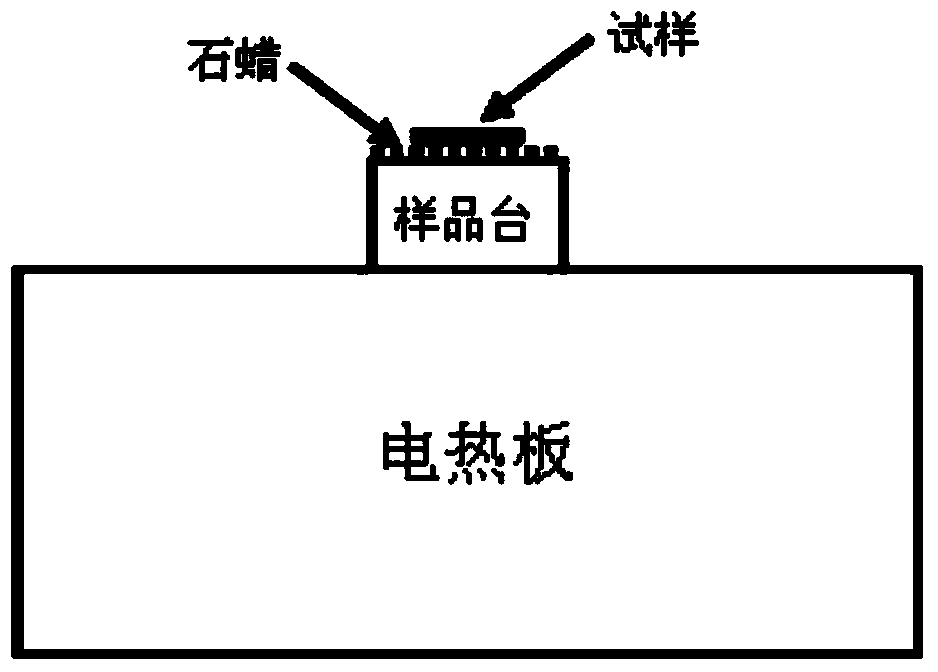

[0033] (2) Select a stainless steel cylinder with a height of 2cm and a diameter of 3cm as the sample stage, place the sample stage on a heating plate and heat it to 60°C, melt an appropriate amount of paraffin evenly on the sample stage, and then sample B The side A sticks to the molten paraffin, and the A side does not touch the paraffin until the paraffin solidif...

Embodiment 2

[0045] The thin-gauge steel material used in the examples is 0.3 mm low-carbon alloy steel, and the equipment used for electron backscatter diffraction analysis is a FEI Quanta400 scanning electron microscope equipped with an Oxford EBSD accessory.

[0046] A sample preparation method for electron backscattered diffraction analysis of thin-gauge iron and steel materials, comprising the steps of:

[0047] (1) Use a precision cutting machine to cut low-carbon alloy steel into small pieces with a plate size of 1.2cm×1.0cm as a sample, and use sandpaper to grind one side of the sample plate. The grinding plane is the B side;

[0048] (2) Select a stainless steel cylinder with a height of 2cm and a diameter of 3cm as the sample stage, place the sample stage on a heating plate and heat it to 70°C, melt an appropriate amount of paraffin evenly on the sample stage, and then sample B The side A sticks to the molten paraffin, and the A side does not touch the paraffin until the paraffi...

Embodiment 3

[0053] The thin-gauge steel material used in the examples is 0.2 mm low-carbon ferritic steel, and the equipment used for electron backscatter diffraction analysis is a FEI Quanta400 scanning electron microscope equipped with Oxford EBSD accessories.

[0054] A sample preparation method for electron backscattered diffraction analysis of thin-gauge iron and steel materials, comprising the steps of:

[0055] (1) Use a precision cutting machine to cut low-carbon ferritic steel into small pieces with a plate size of 1.0cm×1.0cm as samples, and use sandpaper to smooth one side of the sample plate, and the ground surface is the A surface , the unground surface is the B surface;

[0056] (2) Select a stainless steel cylinder with a height of 2cm and a diameter of 3cm as the sample stage, place the sample stage on a heating plate and heat it to 65°C, melt an appropriate amount of paraffin evenly on the sample stage, and then sample B The side A sticks to the molten paraffin, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com