Hoop connector six-plate diversion vertical one-way valve made of titanium alloy

A technology of clamp joints and titanium alloys, applied in sliding valves, valve details, control valves, etc., can solve problems such as affecting oil well production, increasing energy consumption, and corrosion of pipeline systems, achieving direct and indirect benefits. Objective, The effect of prolonging the service life and avoiding unexpected failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention will be further described with embodiment:

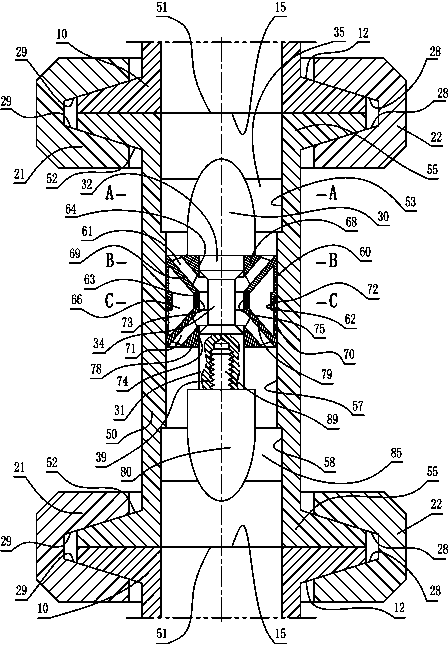

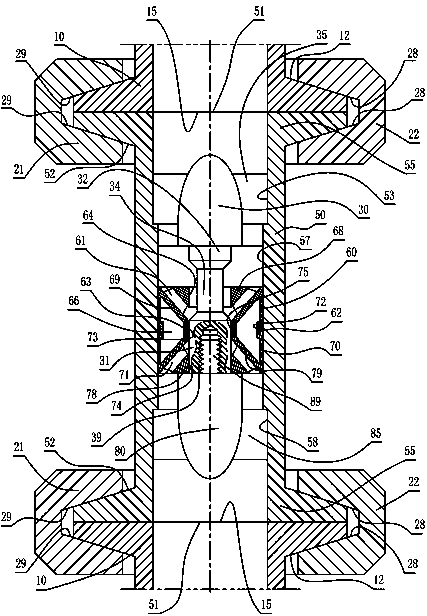

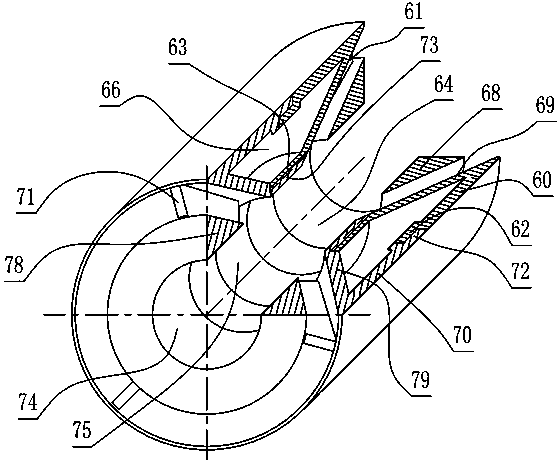

[0034] Figure l, figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Among them, a clamp joint six-plate guide titanium alloy vertical one-way valve includes a clamp joint valve body 50, an upper guide body 30, a lower guide body 80, an upper half spool 60 and a lower half spool 70. The lower end of the outer circle of the clamp joint valve body 50 has a lower pipe clamp head 59, and the lower end of the outer circle of the clamp joint valve body 50 has a pipe clamp head 54, and the outer circumference of the lower pipe clamp head 59 The end face has a valve lower pipe plane 91 and the inlet pipe plane 19 on the outer end surface of the system inlet pipe joint 18 in airtight contact, and the outer end surface of the outlet pipe clamp head 54 has a valve outlet pipe plane 41 and the outer end surface of the system outlet pipe joint 13 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com