R-t-b sintered magnet

A R-T-B, sintered magnet technology, applied in the direction of magnetic objects, magnetic materials, inorganic material magnetism, etc., can solve the problems of low thermal stability, reduced coercive force, temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

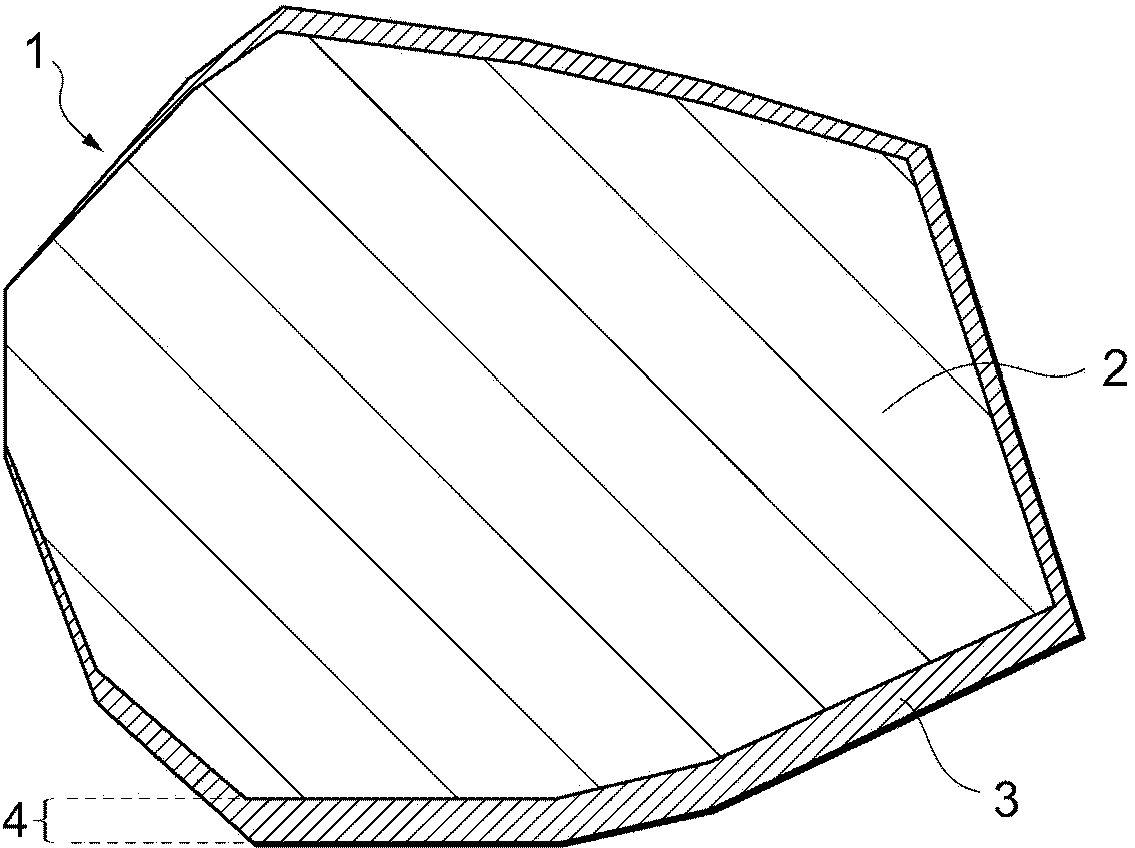

Image

Examples

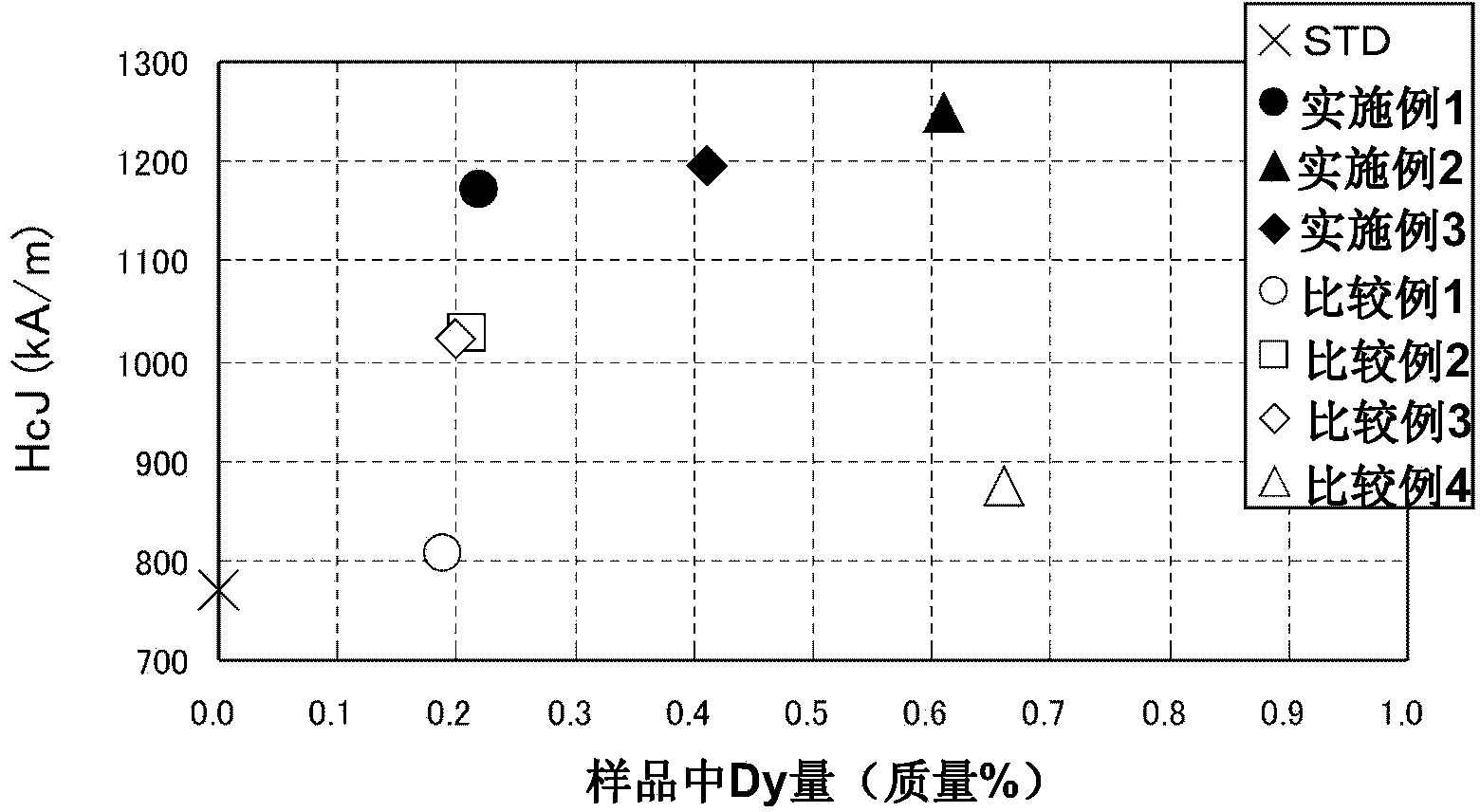

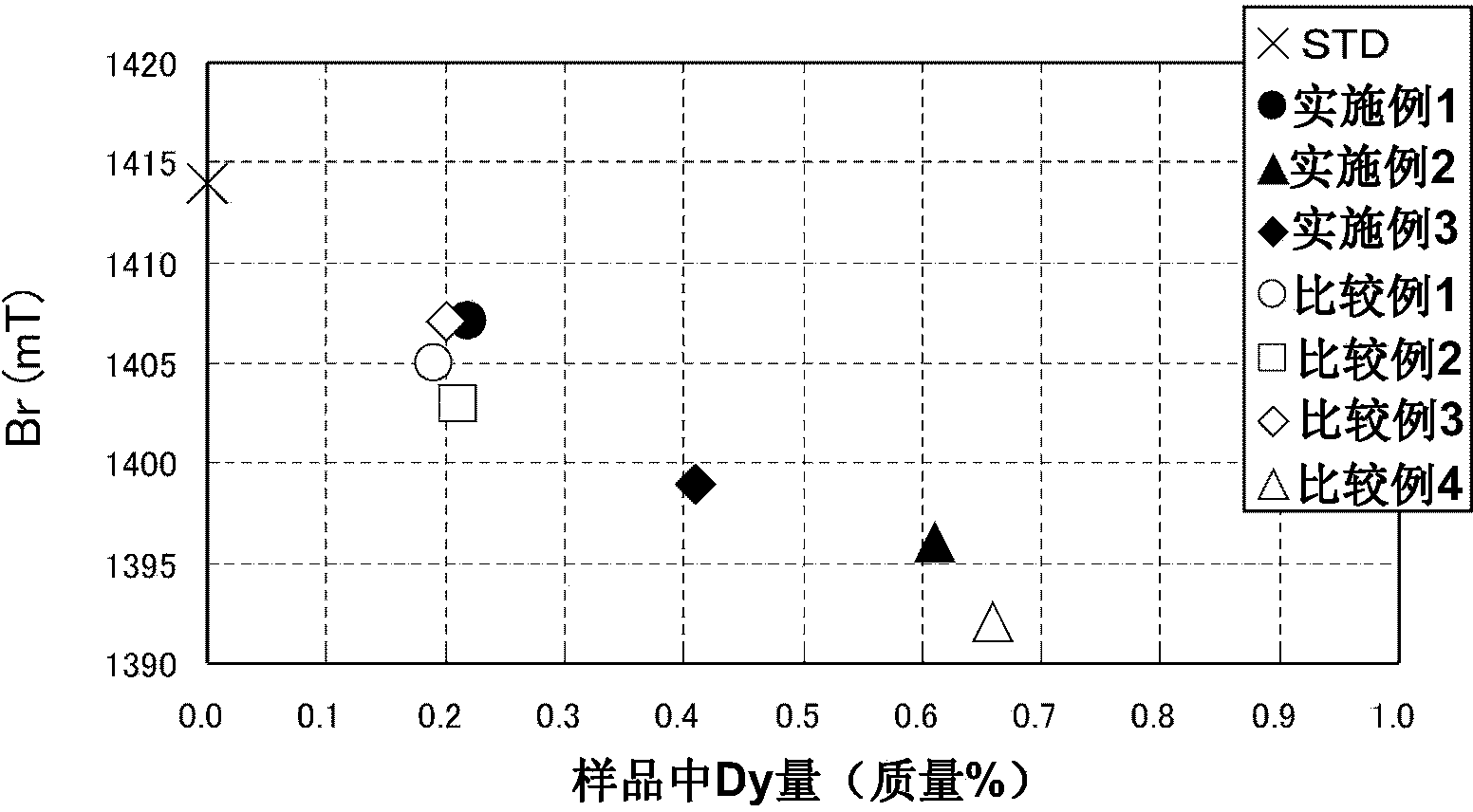

Embodiment 1

[0058] Raw material alloys having compositions A and D in Table 1 were produced by strip continuous casting.

[0059] The prepared raw material alloy A and raw material alloy D were mixed at a mixing ratio of 0.95 / 0.05, and hydrogen storage was performed at room temperature for 90 minutes, followed by dehydrogenation treatment at 650° C. for 60 minutes in an argon atmosphere and coarse pulverization.

[0060] 0.10% by mass of oleic acid amide was added as a grinding aid to the coarsely ground powder of the raw material alloy. Thereafter, it was finely pulverized by a jet mill using high-pressure nitrogen to obtain a finely pulverized powder with an average particle diameter of 4.0 μm.

[0061] [Table 1]

[0062]

[0063] An ingot corresponding to the composition of G was high-frequency melted, and the molten metal was rapidly cooled by a roll to form a thin strip of a Dy alloy compound including the composition of G in Table 1. The produced ribbon is pulverized by a dry m...

Embodiment 2

[0070] The raw material alloy with the composition of A and D in Table 1 was finely pulverized in the same manner as in Example 1, and the compound of the alloy containing Dy in the composition of G in Table 1 was prepared in the same manner as in Example 1, with a concentration of 0.80% by mass. It was added to the finely pulverized powder of the raw material alloy, and an evaluation sample was produced in the same manner as in Example 1.

Embodiment 3

[0072] Evaluation samples were prepared in the same manner as in Example 1 except that the raw material alloys having the compositions B and D in Table 1 were used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com