Low-temperature flexible high-friction composite brake shoe

A synthetic brake shoe, low-temperature flexible technology, applied in friction linings, mechanical equipment, etc., can solve problems such as hidden dangers of driving safety, air pollution, poor thermal conductivity, etc., to achieve stable friction performance, solve air pollution, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

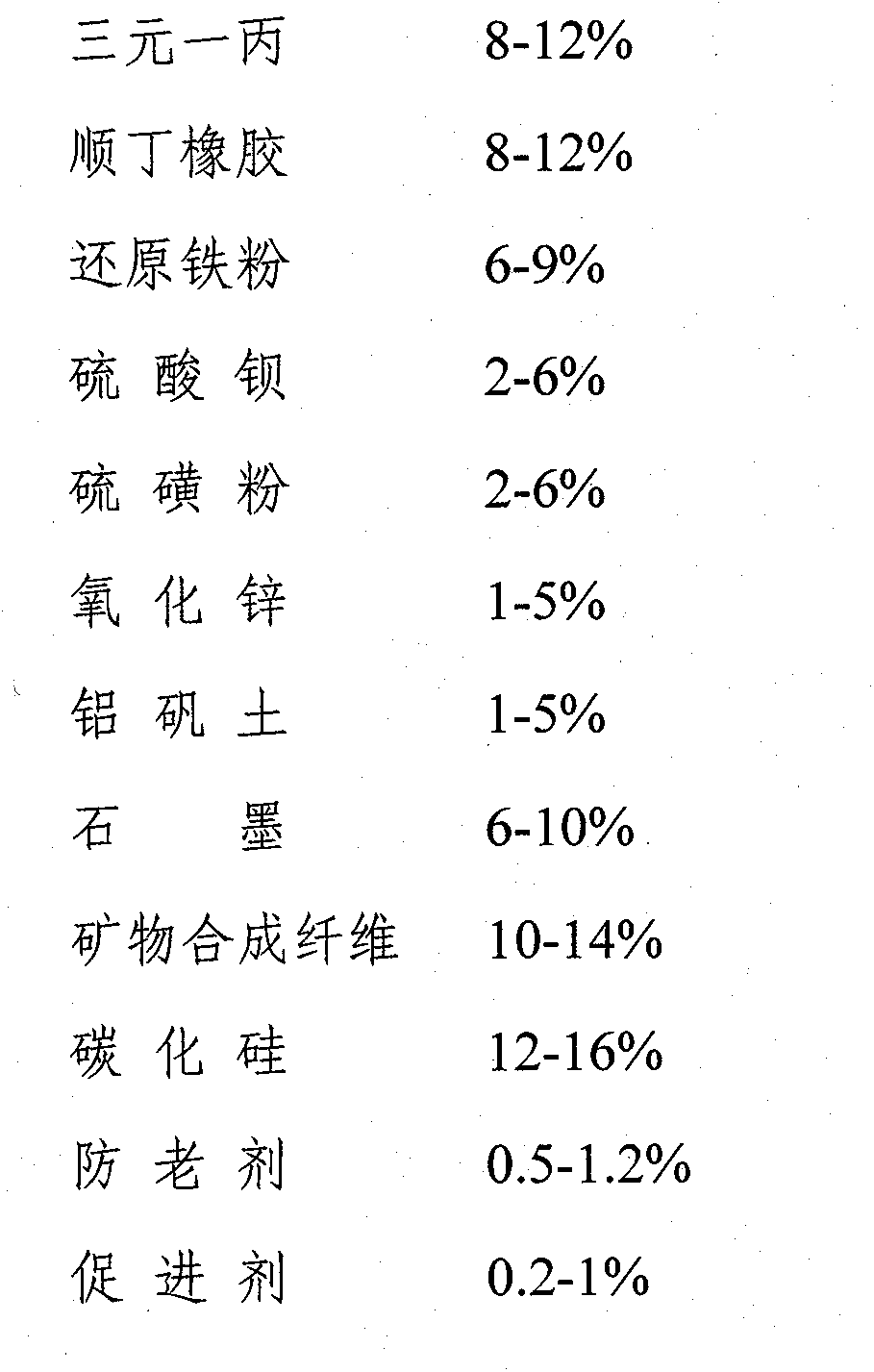

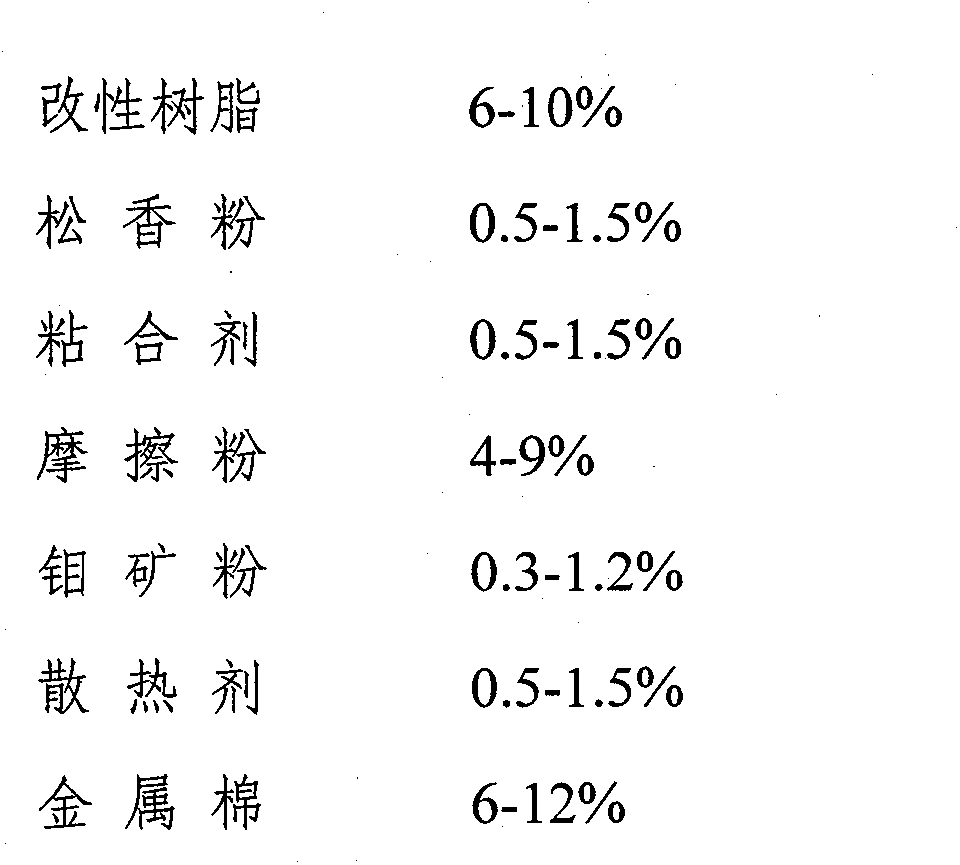

[0012] One of the low-temperature flexible high-friction synthetic brake shoe material formulas:

[0013]

[0014]

Embodiment 2

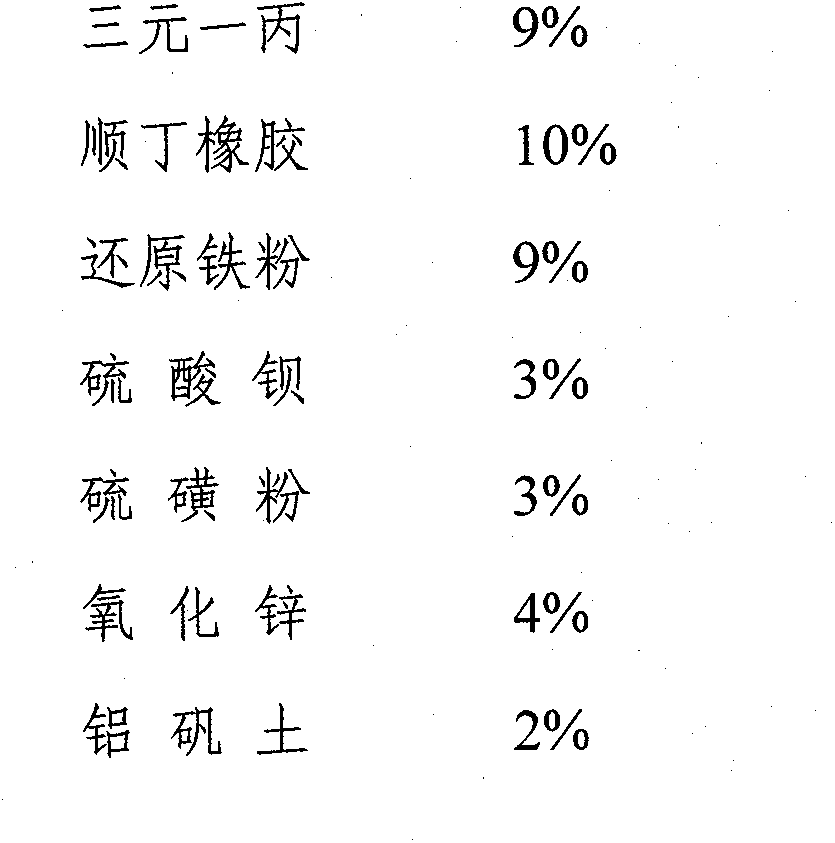

[0016] Low temperature flexible high friction synthetic brake shoe material formula 2:

[0017]

[0018]

Embodiment 3

[0020] The third formula of low temperature flexible high friction synthetic brake shoe material:

[0021]

[0022]

[0023] The low-temperature flexible high-friction synthetic brake shoe manufactured by the formula of the present invention has been tested by the Product Quality Supervision and Inspection Center of the Ministry of Railways, and its performance indicators are all better than the standards issued by the Ministry of Railways, and its wear and temperature rise indicators are particularly prominent. The wheel-rail impact of loading and running on American railways is small and stable. After many tests, the friction consumption of low-temperature flexible high-friction synthetic brake shoes is much lower than the Ministry of Railways standard, and the temperature rise of the tread is low, with a maximum temperature rise of 141 degrees Celsius. The technical conditions allow a temperature of 400 degrees Celsius. Therefore, it not only effectively ensures the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com