Halogen-free non-phosphorus flame-retarded resin composition

A technology of resin composition and flame-retardant resin, which is applied in the direction of synthetic resin layered products, film/sheet-like adhesives, layered products, etc., and can solve problems such as low moisture resistance, aquatic biological hazards, and poor heat resistance. , achieve good heat resistance and toughness, improve water absorption performance, and improve thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-limiting embodiment of the present invention is as follows:

[0073] In the examples and comparative examples, unless otherwise specified, the parts represent parts by weight, and the % represents "% by weight".

[0074] The formulations of the resin compositions provided in Examples 1-10 are shown in Table 1.

[0075] The formula of the resin composition that table 1 embodiment 1~10 provides

[0076]

[0077]

[0078] The formulations of the resin compositions provided in Comparative Examples 1-7 are shown in Table 2.

[0079] The formula of the resin composition that table 2 comparative example 1~7 provides

[0080]

[0081]

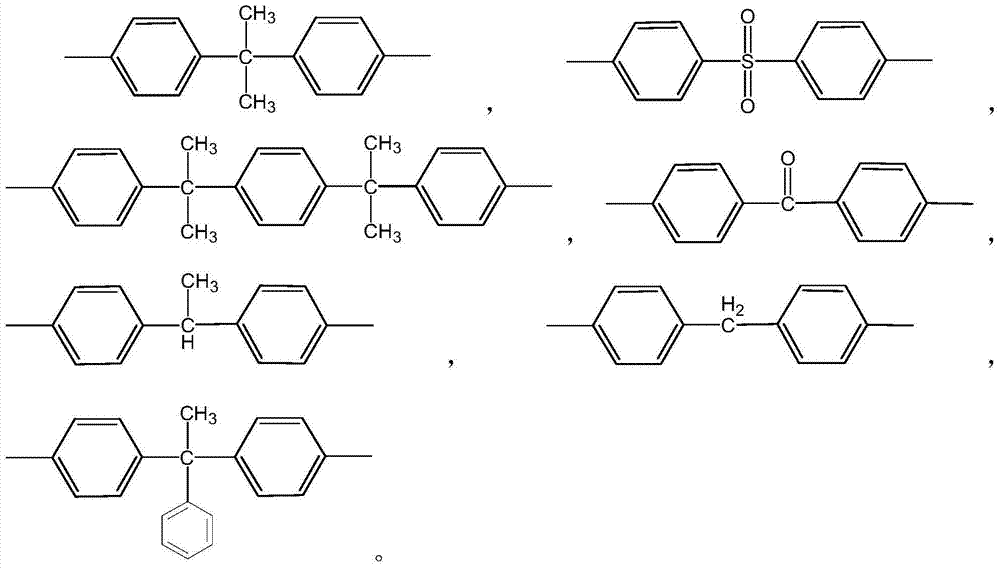

[0082] In Table 1 and Table 2, bisphenol A is bisphenol A type epoxy resin, 8093 of Haus Mai Huntsman, epoxy equivalent 480g / mol;

[0083] DCPD is dicyclopentadiene epoxy resin, HP-7200H from DIC in Ja...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com