Double-sided tape and production method thereof

A double-sided tape and adhesive technology, applied in the direction of adhesive, epoxy glue, adhesive type, etc., can solve problems such as difficult to remove for replacement or storage, poor wall adhesion performance, and no type selection. , to achieve the effect of performance improvement, recovery of bond strength, bond strength and peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

[0037] Embodiment 6, a double-sided adhesive tape, differs from Embodiment 3 in that the tackifying resin is rosin resin.

Embodiment 7

[0038] Embodiment 7, a double-sided adhesive tape, differs from Embodiment 3 in that the tackifying resin is a 1:1 compound of rosin resin and petroleum hydrogenated resin.

Embodiment 8

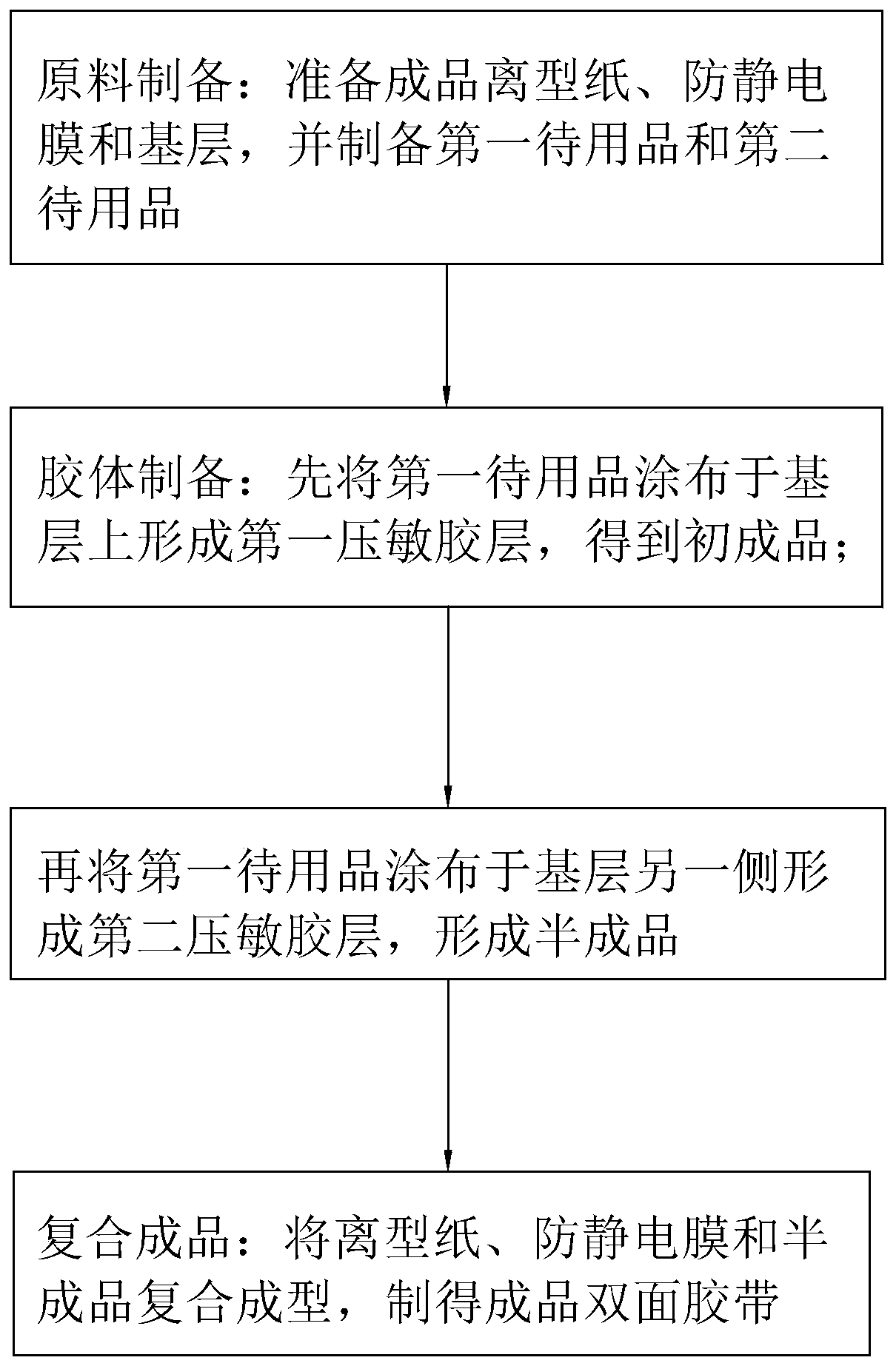

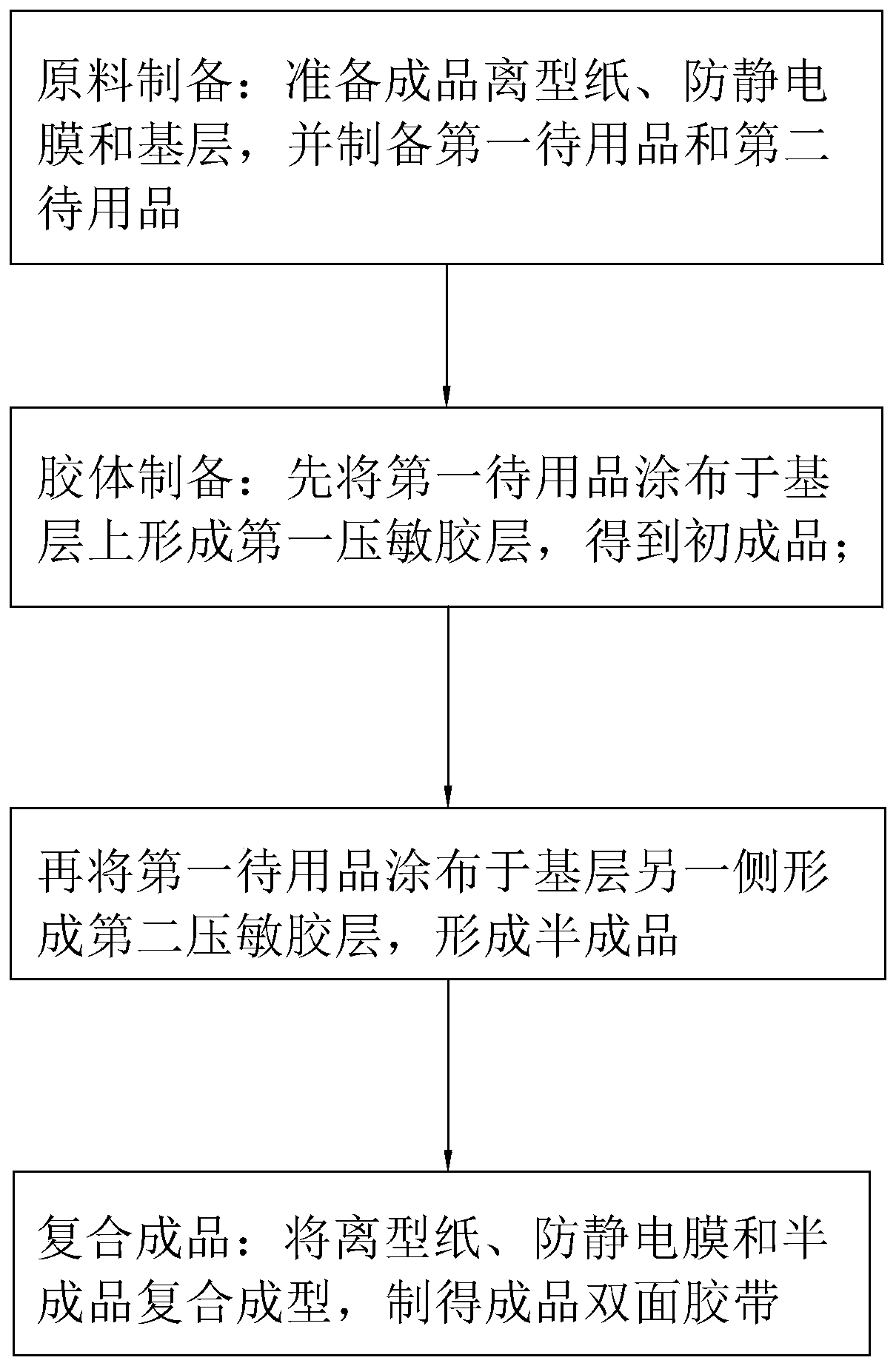

[0039] Embodiment 8, a production method of double-sided adhesive tape, the components used are all the components in Embodiment 3, and the content and corresponding process steps are as follows:

[0040] S1, raw material preparation, preparing the base layer composed of finished release paper, polyester antistatic film layer and biaxially stretched colorless and transparent polyethylene terephthalate and polyimide;

[0041] At the same time, get 11 parts of epoxy resin adhesive, 0.1 part of coupling agent, 0.3 part of leveling agent, 0.2 part of defoamer, 0.5 part of accelerator, and 1 part of talcum powder to mix and heat fully to obtain The first ready-to-use product for preparing the first pressure-sensitive adhesive layer and the second pressure-sensitive adhesive layer;

[0042] At the same time, take 18 parts of acrylate, 16 parts of thermoplastic elastomer, 4 parts of microcrystalline wax, 12 parts of synthetic wax, 32 parts of tackifying resin, 5 parts of curing agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com