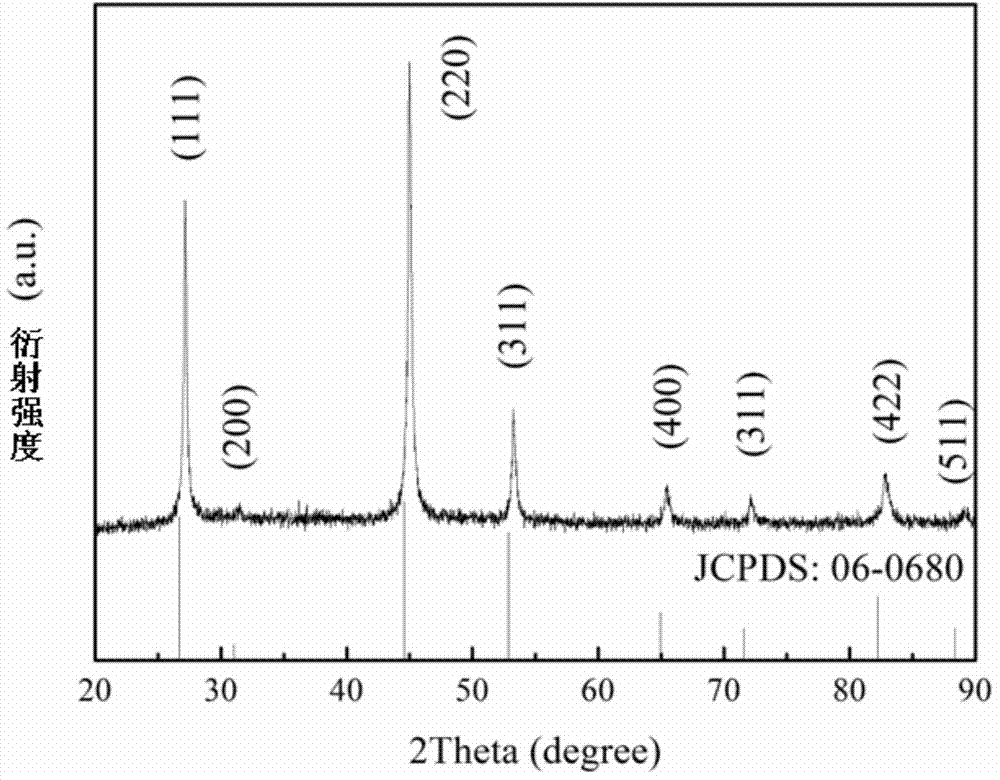

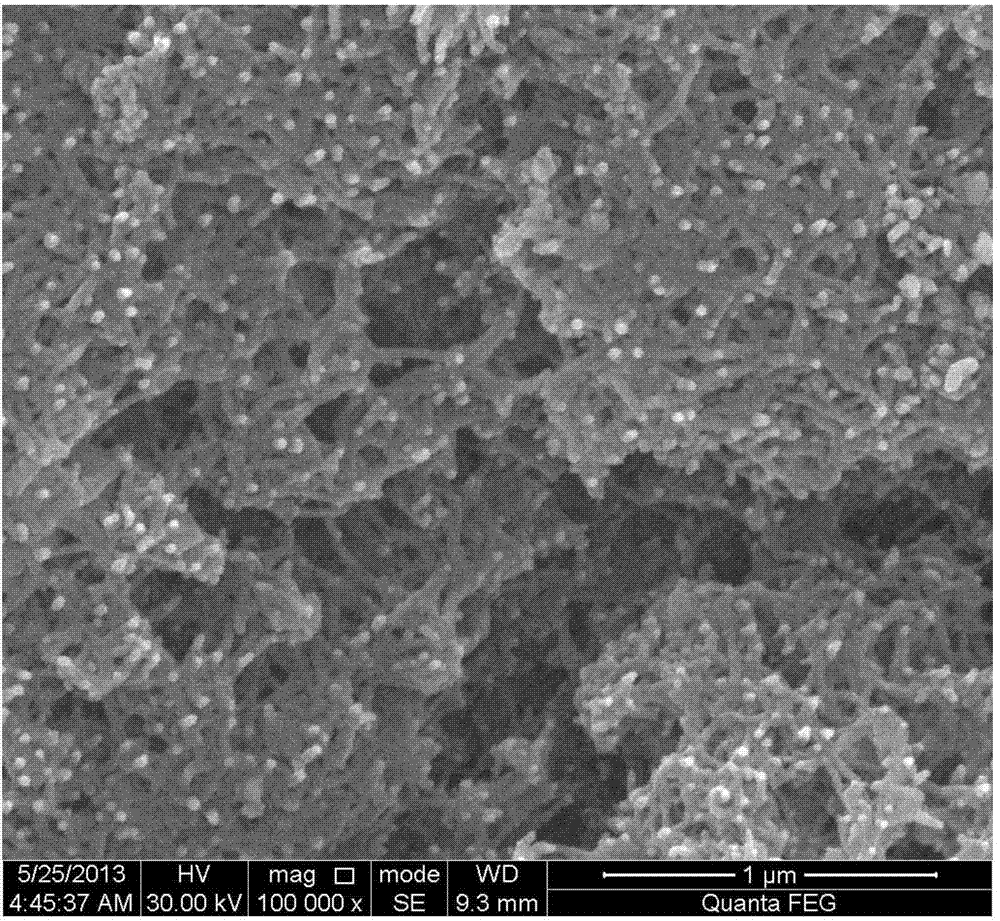

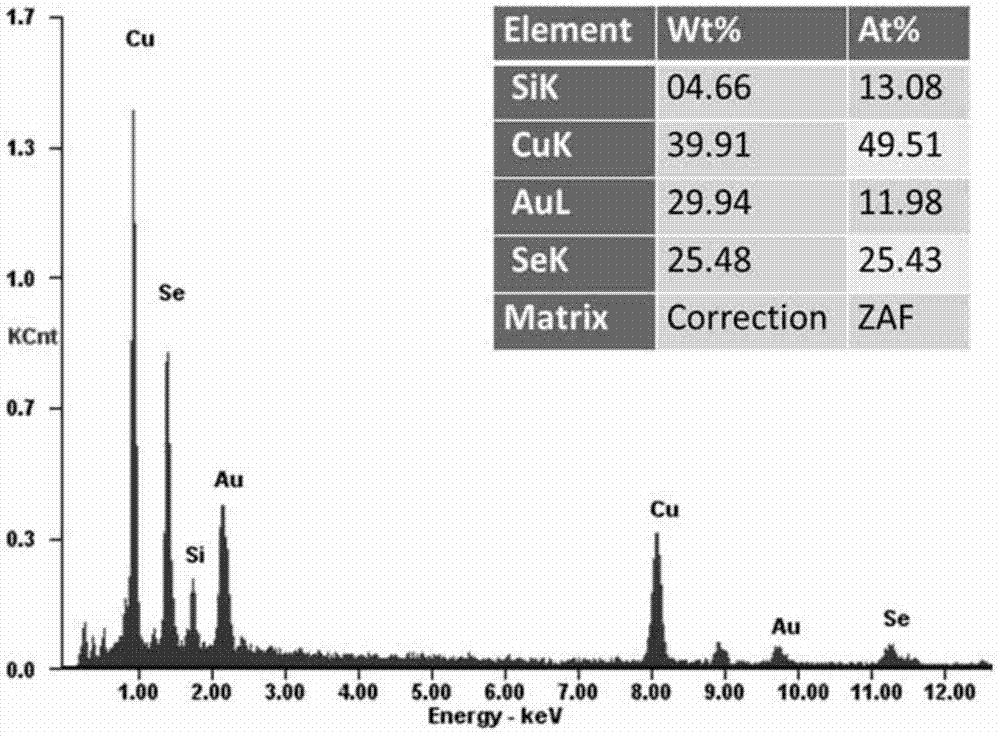

Method for preparing copper selenide nanowires by microwave-assisted method

A microwave-assisted, copper selenide technology, applied in the direction of nanotechnology, binary selenium/tellurium compounds, etc., can solve the problems of slow heating speed of copper selenide nanowires, unfavorable expansion of production, low heat utilization rate, etc., to achieve the preparation process Environmentally friendly and efficient, easy to promote, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: In this embodiment, a method for preparing copper selenide nanowires by a microwave-assisted method is realized according to the following steps:

[0022] 1. Put 0.16~0.20g of Cu(CH 3 COO) 2 ·H 2 O, 0.08-0.12g of Na 2 SeO 3 , 0.3-0.5g of sodium tartrate was dissolved in 40mL of formamide, and then placed on a magnetic stirrer and stirred at a stirring speed of 4000-8000r / min for 8-20min to obtain a mixed solution A;

[0023] 2. Add 0.3-1.0g of KOH into 10mL of formamide, stir until dissolved, and obtain solution B;

[0024] 3. Add solution B to mixed solution A, then add 0.2-2.0mL hydrazine hydrate dropwise and mix well to obtain mixed solution C;

[0025] 4. Add the mixed solution C into a three-necked flask, put it into a microwave reactor, and then treat it with microwave radiation at a temperature of 160-190°C for 10-20 minutes, and cool it naturally to room temperature to obtain Cu 2-x Se nanowire precursor;

[0026] Five, the Cu 2-...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, 0.18g of Cu(CH 3 COO) 2 ·H 2 O, 0.09g of Na 2 SeO 3 , 0.4g of sodium tartrate was dissolved in 40mL of formamide. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0032] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 1, it is placed on a magnetic stirrer and stirred at a stirring speed of 6000 r / min for 15 min. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com