Method for melting titanium scraps and pure titanium wastes of thin titanium plates by electron beam cold hearth melting furnace

An electron beam cooling bed furnace and electron beam cooling bed technology, which is applied in the field of melting titanium scraps and thin titanium plate pure titanium waste by electron beam cooling bed melting furnace cold bed smelting technology, can solve the problem of reducing the recycling quality and use ratio of titanium waste Limitations, low utilization rate of titanium waste, etc., to avoid violent fluctuations in chemical composition, improve quality, and remove high and low density inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Example 1: Common TA1 smelting

[0070] Raw materials: Grade 0 titanium sponge + 17% TA1 crushed titanium shavings

[0071] Equipment: EBCHR 6 / 200 / 3600 electron beam cooling hearth furnace.

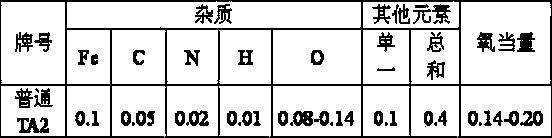

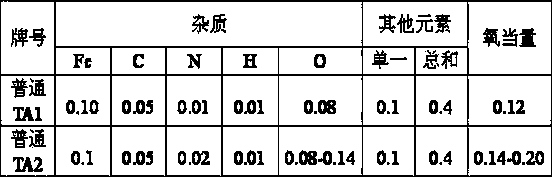

[0072] The chemical composition of the slabs is defined as shown in Table 2.

[0073] Table 2

[0074]

[0075] Actual smelting process:

[0076] A. Raw material preparation: TA1 pure titanium and titanium chips are crushed with a pulverizer (the inner wall of the pulverizer is made of stainless steel to prevent rust pollution).

[0077] B. Ingredients: Select 2 barrels of grade 0 titanium sponge (250kg) and 1 barrel of TA1 crushed titanium scraps (100kg / barrel), and put them into the mixer for mixing in turn. Pour out after mixing for 5 minutes, and seal the barrel for later use. Continue to mix 66 barrels according to the above method.

[0078] C. Deflate the drum, and put 10 barrels of mixed materials into the drum through the feeding trolley and vacuumize. Afterwards...

Embodiment 2

[0095] Embodiment 2: ordinary TA2 smelting

[0096] Raw materials: 29% crushed recycled materials + grade 0 titanium sponge + titanium dioxide.

[0097] Equipment: EBCHR 6 / 200 / 3600 electron beam cooling hearth furnace.

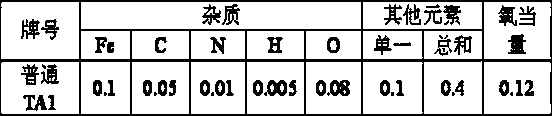

[0098] The chemical composition of the slab is defined in Table 4.

[0099] Table 4

[0100]

[0101] Actual smelting process:

[0102] A. Raw material preparation: Use hydraulic shears to crush TA2 block materials with a thickness of ≤4.5mm.

[0103] B. Ingredients: Select 1 barrel of grade 0 titanium sponge (250kg) and 1 barrel of TA2 crushed material (100kg / barrel), and configure titanium dioxide material bags, and put them into the mixer for mixing in turn. Pour out after mixing for 5 minutes, and seal the barrel for later use. Continue to mix 76 barrels according to the above method.

[0104] C. Deflate the drum, and put 10 barrels of mixed materials into the drum through the feeding trolley and vacuumize. Afterwards, every time you feed, you ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com