Method for preparing calcium-magnesium acetate by utilizing steel slag

A technology of calcium magnesium acetate and steel slag, which is applied in the direction of carboxylate preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of endangering farmland, water sources and green belts, denudation damage, high price, etc., and achieves formula and simplicity , Simple production process, easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

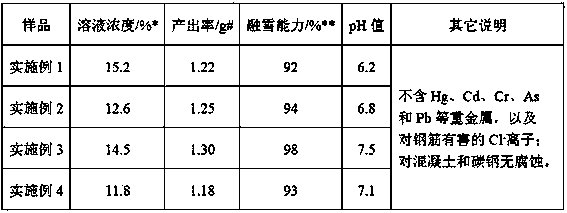

Examples

Embodiment 1

[0015] (1) Steel slag / acetic acid mass ratio=1.0:1;

[0016] (2) The concentration of acetic acid is 15%;

[0017] (3) Reaction conditions: temperature is 20°C; reaction time is 4h.

Embodiment 2

[0019] (1) Steel slag / acetic acid mass ratio=1.5:1;

[0020] (2) The concentration of acetic acid is 10%;

[0021] (3) Reaction conditions: temperature is 30°C; reaction time is 8h.

Embodiment 3

[0023] (1) Steel slag / acetic acid mass ratio=2:1;

[0024] (2) The concentration of acetic acid is 10%;

[0025] (3) Reaction conditions: temperature is 40°C; reaction time is 2h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com