Preparation method of wide-temperature, high-pressure-resistant and high-energy-density ceramic dielectric material

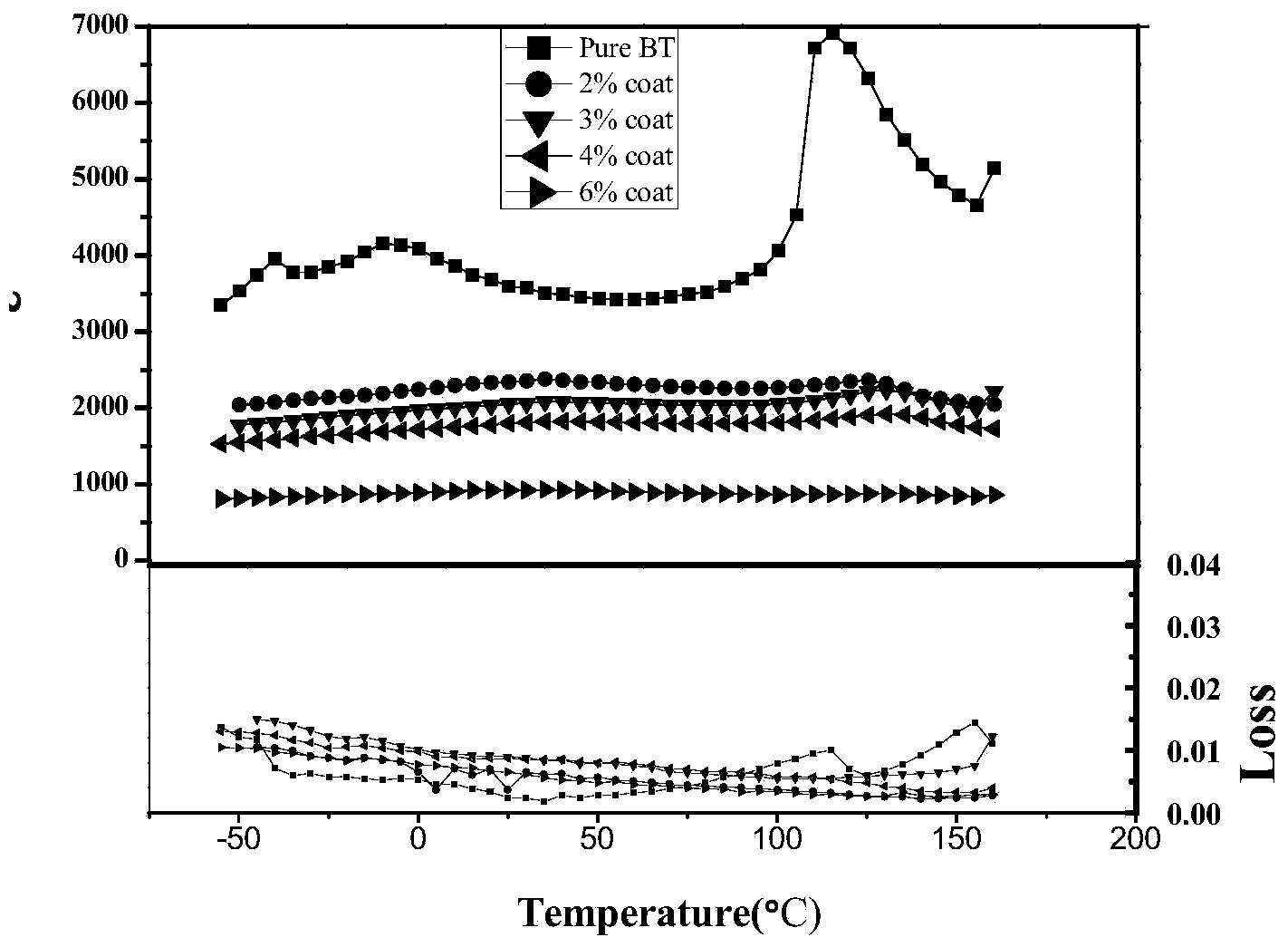

A technology of high energy storage density and ceramic medium, which is applied in the preparation of BaTiO3-based ceramic dielectric materials and energy storage medium materials, can solve the problems of unstable dielectric constant and low energy storage density, and achieve low cost, Good repeatability and the effect of improving the withstand voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Wide temperature and high pressure resistant high energy storage density material: 100wt% BaTiO 3 -2wt%SiO 2

[0029] 1) 20g300nmBaTiO 3 Place the ceramic powder in solution A (a mixture of ethanol and glacial acetic acid) at pH=4, stir in a water bath at 40-80°C for 40-90 minutes, and ultrasonically disperse at 40-50°C for 40-55 minutes to obtain a suspension B;

[0030] 2) Add 1.4085g tetraethyl orthosilicate with a purity greater than 99.9% to the B suspension, and mark it as C suspension;

[0031] 3) Stir the C suspension for 30-50 minutes, so that the tetraethyl orthosilicate is evenly distributed in the ethanol and the surface of the powder, and obtain the D suspension;

[0032] 4) Stir the D suspension and add ammonia water dropwise at a rate of about 3 s / d. The metal alkoxide is hydrolyzed by adding ammonia water, and the pH is controlled at about 9 to obtain a viscous E slurry;

[0033] 5) After stirring the slurry E for 10-12 hours, wash it with deionized ...

Embodiment 2

[0039] Wide temperature and high pressure resistant high energy storage density material: 100wt% BaTiO 3 -3wt%SiO 2

[0040] 1) 20g300nmBaTiO 3 Place ceramic powder in A solution (a mixture of ethanol and glacial acetic acid) with pH=4, stir in a water bath at 40-80°C for 40-90 minutes, and ultrasonically disperse at 40-80°C for 40-90 minutes to obtain B suspension;

[0041]2) Add 2.1127g of tetraethyl orthosilicate with a purity greater than 99.9% to B suspension, and mark it as C suspension;

[0042] 3) Stir the C suspension for 50-60 minutes, so that the tetraethyl orthosilicate is evenly distributed in the ethanol and the surface of the powder, and obtain the D suspension;

[0043] 4) Stir the D suspension and add ammonia water dropwise at a rate of about 5 s / d. The metal alkoxide is hydrolyzed by adding ammonia water, and the pH is controlled at about 9 to obtain a viscous E slurry;

[0044] 5) After stirring the E slurry for 11-12 hours, wash it with deionized water ...

Embodiment 3

[0050] Wide temperature and high pressure resistant high energy storage density material: 100wt% BaTiO 3 -4wt%SiO 2

[0051] 1) 20g300nmBaTiO 3 Place ceramic powder in A solution (a mixture of ethanol and glacial acetic acid) with pH=4, stir in a water bath at 40-80°C for 60 minutes, and ultrasonically disperse at 60°C for 60 minutes to obtain B suspension;

[0052] 2) Add 2.8169g of tetraethyl orthosilicate with a purity greater than 99.9% to B suspension, and mark it as C suspension;

[0053] 3) Stir the C suspension for 60 minutes, so that the tetraethyl orthosilicate is evenly distributed in the ethanol and the surface of the powder, and obtain the D suspension;

[0054] 4) Stir the D suspension and add ammonia water dropwise at a rate of about 7 / d. The metal alkoxide is hydrolyzed by adding ammonia water, and the pH is controlled at about 9 to obtain a viscous E slurry;

[0055] 5) After stirring the slurry E for 10-14 hours, wash it with deionized water or absolute e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com