Water treatment method and equipment of photocatalytic composite membrane bioreactor

A technology of bioreactor and water treatment equipment, applied in the field of water treatment of photocatalysis-composite membrane bioreactor, to achieve the effect of strong sewage treatment capacity, less residual sludge and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

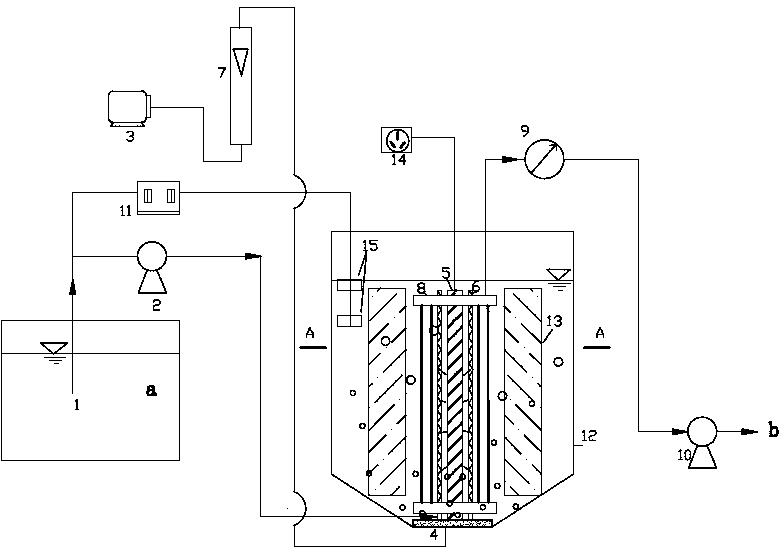

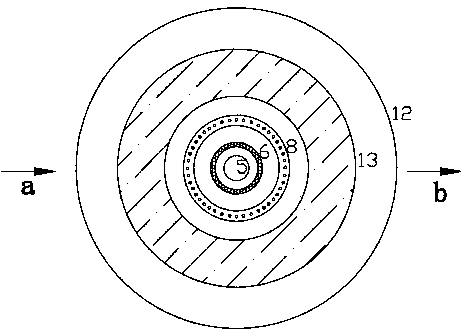

[0025] Embodiment 1: as figure 1 and figure 2 as shown,This device is mainly composed of aeration tank 12 and other auxiliary devices, including: water inlet tank 1, water inlet pump 2, air compressor 3, aeration disc 4, ultraviolet lamp 5, catalyst layer 6, gas flow meter 7, membrane module 8 , Vacuum pressure gauge 9, outlet pump 10, liquid level automatic control system 11, aeration tank 12, biofilm carrier 13, power supply 14 and float switch 15. Sewage containing trace pollutants enters between the ultraviolet lamp tube 5 and the catalyst carrier 6 from the bottom through the water inlet pool 1 . The bottom of the aeration tank 12 is provided with a microporous aeration disc 4 for aeration, and the dissolved oxygen concentration is kept at 4-6 mg / L. The center of the aeration tank 12 is vertically arranged with an ultraviolet lamp 5 surrounded by a titanium dioxide catalyst 6. The outer layer of the catalyst layer 6 surrounds the membrane module 8, and a biofilm ca...

Embodiment 2

[0027] Embodiment 2: Adopt the device described in embodiment 1, apply this device to the sewage containing tetracycline hydrochloride and carry out small-scale research. The operating parameters of the process are: the hydraulic retention time is 24h, the sludge age is 25 days, the sludge concentration is about 4000 mg / L, the influent flow rate is 0.25L / h, and the influent NH 4 + -N is about 90mg / L. The concentration of tetracycline hydrochloride is 400mg / L, and the light intensity is 360μW / cm 2 . When the light time was 120min, the removal rate of tetracycline hydrochloride reached 80%. 4 + -N removal rate reaches 95%, NH 4 + The average effluent concentrations of -N and tetracycline hydrochloride were 4.5 mg / L and 80 mg / L, respectively. After 24 hours of reaction time, the removal rate of tetracycline hydrochloride was 99.5%, and NH 4 + -N removal rate is 99%, NH 4 + -N and tetracycline hydrochloride average effluent concentrations are: 0.1mg / L and 2mg / L respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com