Preparation of linear amino modified graphene oxide adsorption material

An adsorption material, graphene technology, applied in adsorption water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of low removal rate, high cost, secondary pollution, etc., to improve regeneration capacity, increase The effect of adsorption capacity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] First, dissolve graphene oxide in ethanol at room temperature, sonicate it for 1 hour to make it uniform, add it to a 500ml three-necked flask, and add a certain amount of ethanol-soluble ethylenediamine. The mass ratio of the reactants is graphene oxide : Ethylenediamine: Ethanol=1:1~10:10~120. During the process of adding ethylenediamine, it can be found that the two react violently, indicating that it is reacting and the ethylenediamine is quickly dissolved. The whole reaction was continuously stirred mechanically in a water bath at 80°C. After the reaction was carried out for 24 hours, the material obtained from the reaction was filtered under reduced pressure and washed with ethanol three times. After being dried at 80°C for 12 hours, a carboxyl and amino group was obtained. Graphene oxide-ethylenediamine adsorption material. In order to ensure the completion of the reaction and improve the ability of the adsorbent to adsorb heavy metal ions, the ethylenediamine was...

experiment example 2

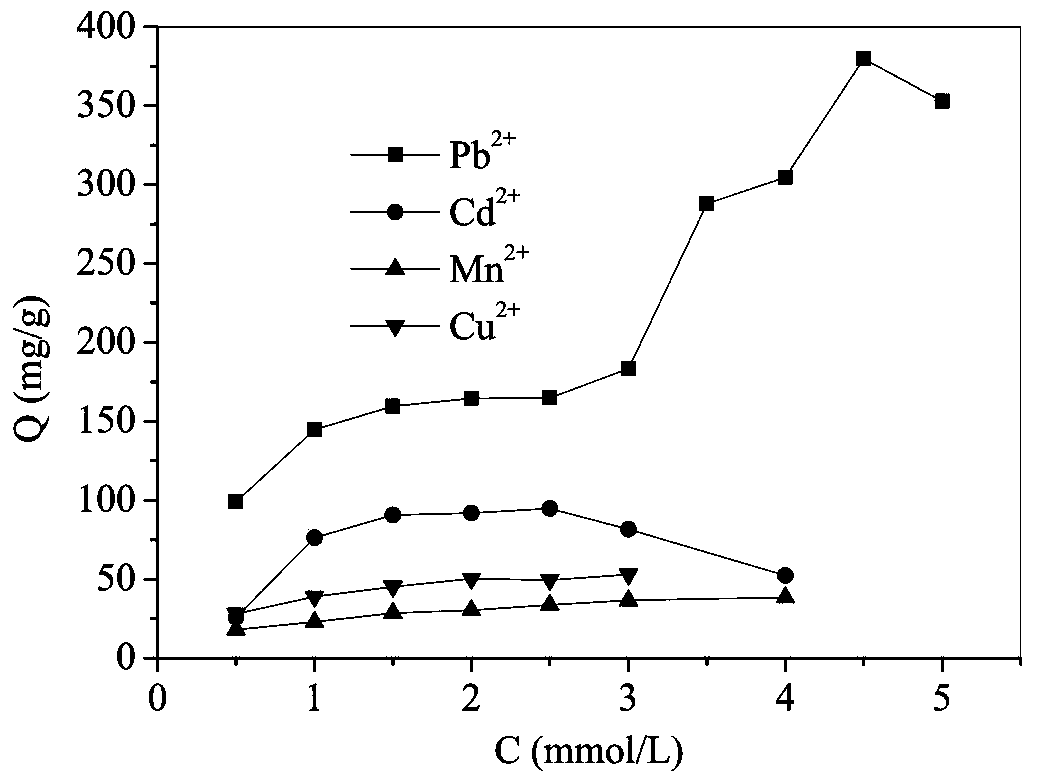

[0021] Weigh 0.1g of the adsorbent prepared in Experimental Example 1 and place them in a 250ml dry round-bottomed flask, and add 100ml of the initial concentration of pH=4.5, concentration C 0 =0.5,1,1.5,2.0,2.5,3.0,3.5,4,4.5 and 5mmol / L Pb(NO 3 ) 2 The solution was oscillated ultrasonically for 1 hour to make the adsorbent dispersed well in the solution, then placed in a constant temperature water bath at 25°C, sealed a round bottom flask, stirred at constant temperature, after 3 hours, take the adsorbed solution and filter it with a funnel, and use atomic absorption spectroscopy The photometer measures the concentration of lead ions remaining in the filtrate, and then calculates the adsorption capacity of the adsorbent according to (1).

[0022] The experimental results show that the adsorbent prepared in Experimental Example 1 has an adsorption capacity of 379.62 mg / g for lead ions under the conditions of a temperature of 25°C and a pH of 4.5.

experiment example 3

[0024] Weigh 0.1g of the adsorbent prepared in Experimental Example 1 and place them in a 250ml dry round-bottomed flask. Add 100ml with an initial concentration of 2mmol / L and pH=2.0,2.5,3.0,3.5,4.0,4.5 and 5.0. Cd(NO 3 ) 2 The solution was oscillated ultrasonically for 1 hour to disperse the adsorbent in the solution well, and then placed in a constant temperature water bath at 25°C. The round bottom flask was sealed and stirred at constant temperature. After 3 hours, the adsorbed solution was taken out and filtered with a funnel, and then filtered by atomic absorption spectroscopy. The photometer measures the concentration of residual cadmium ions in the filtrate, and then calculates the adsorption capacity of the adsorbent according to (1).

[0025] The experimental results show that the adsorption capacity of cadmium ions at pH=2.0,2.5,3.0,3.5,4.0,4.5 and 5.0 is 14.56~113.6mg / g under the temperature condition of 25℃. Among them, under the condition of pH=5.0, experimental exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com