Epitaxial growth method with p-layer special doped structure

An epitaxial growth, special technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of difficult to generate high carrier concentration, growth conditions, reduce material quality and other problems, to reduce the self-compensation effect , Improve crystal quality, improve the effect of doping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

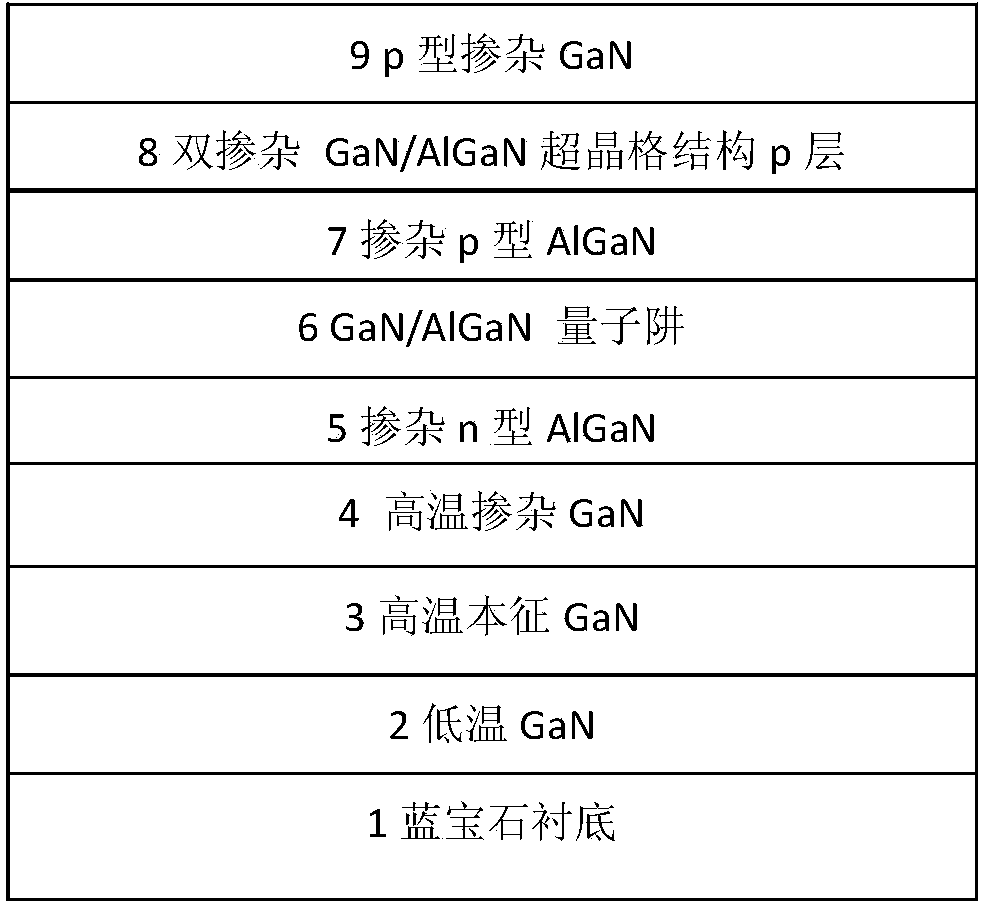

[0044] The present invention will be further elaborated below in conjunction with the accompanying drawings.

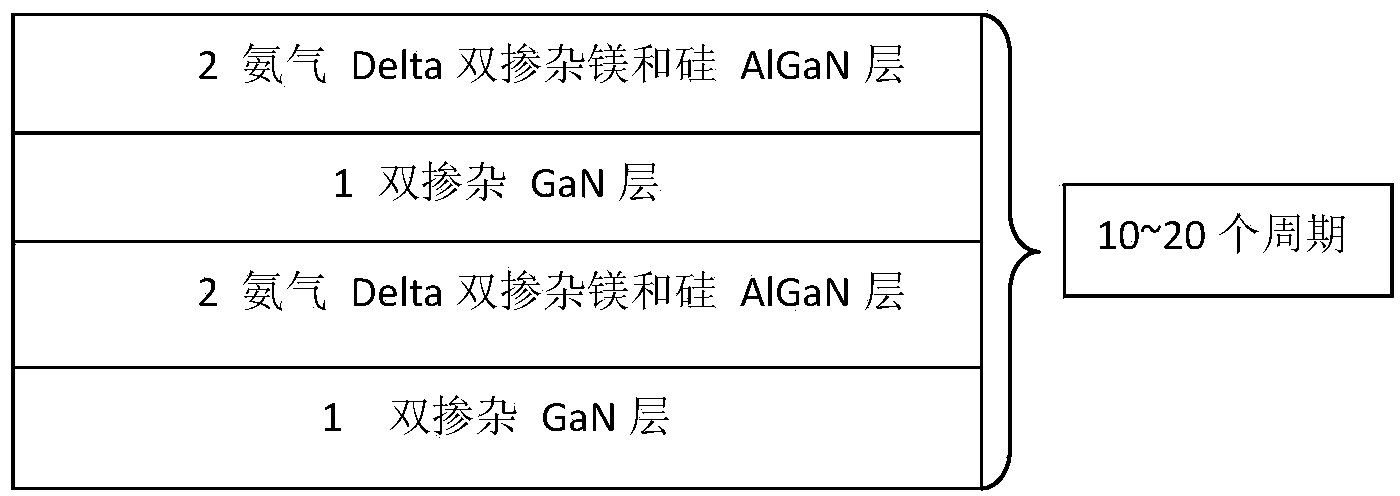

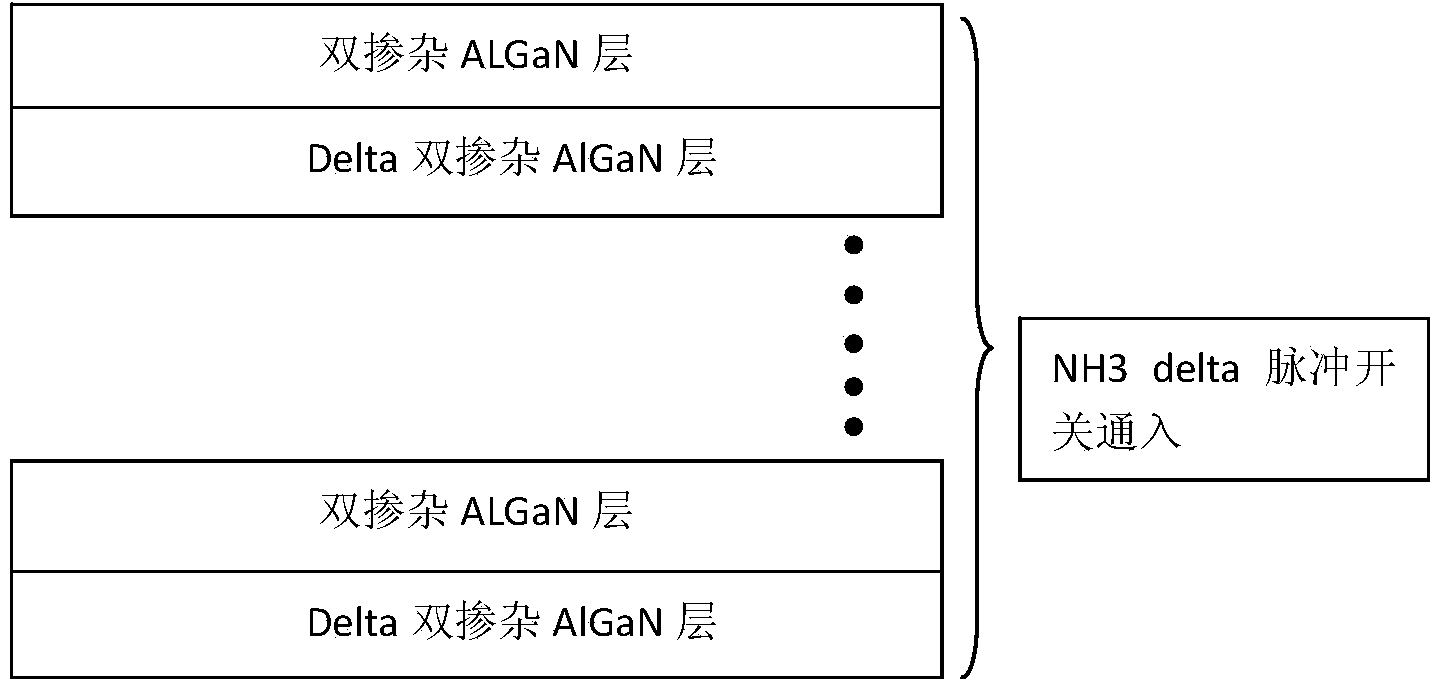

[0045] The present invention applies metal organic compound chemical vapor deposition (MOCVD) epitaxial growth technology, utilizes existing MOCVD technology equipment, uses trimethylgallium (TMGa), triethylgallium (TEGa), and trimethylindium (TMIn), Trimethylaluminum (TMAl) and ammonia (NH3) silane (SiH4) and dimagnesium (cp2Mg) respectively provide gallium source, indium source, aluminum source, and nitrogen source, magnesium source, silicon source required for growth, using NH3 pulsed delta doping is used to prepare p-layer superlattice structure with double element doping, which further combines the advantages of delta doping and double doping.

[0046] A specific example of the epitaxial growth method is as follows:

[0047] 1. After the sapphire substrate is specially cleaned, put it into the MOCVD equipment and bake it at 1100°C for 10 minutes.

[0048] 2. Lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com