Method for manufacturing heat-storage forging heating furnace by utilizing quartzitic sandstone

A forging heating and regenerative technology, used in lighting and heating equipment, furnaces, furnace components, etc., can solve the problems of poor high temperature corrosion resistance, high maintenance frequency, short service life, etc., to achieve high refractoriness, obvious pores Low rate, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

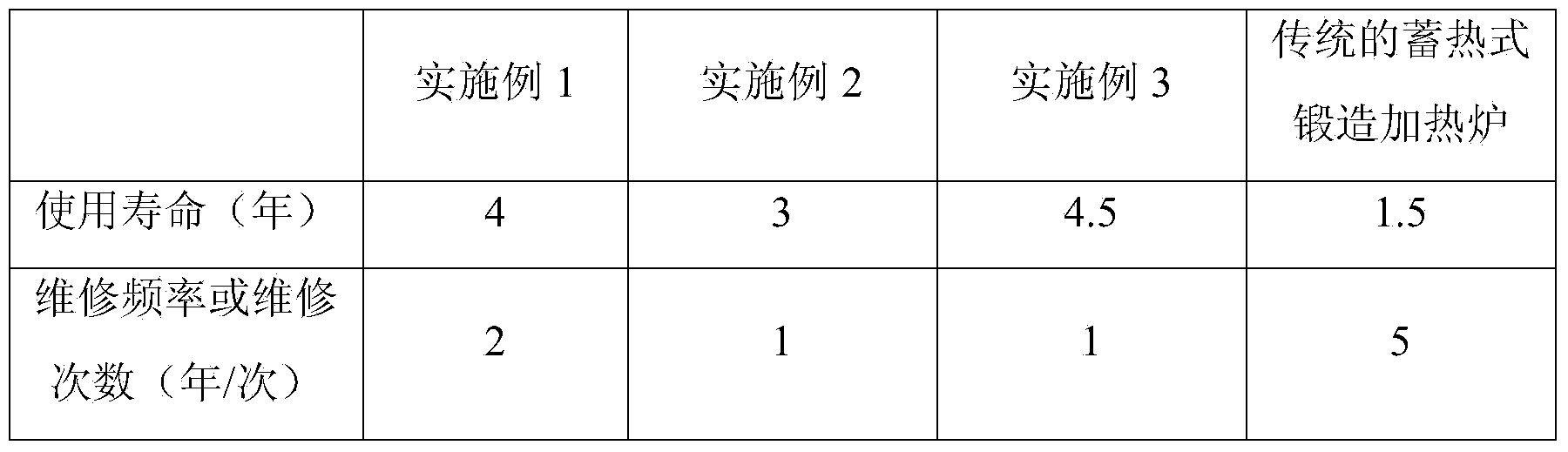

Examples

Embodiment 1

[0025] First, design the furnace body structure of the regenerative forging heating furnace, then design the corresponding furnace scheme according to the gas source of the manufacturer, prepare and repair the refractory white foam stone bricks according to the needs, and finally use white foam bricks according to the furnace structure diagram Foam stone bricks are used as the refractory layer of the furnace wall and roof to create a regenerative forging furnace. After the furnace is formed, it is baked according to the furnace plan. The oven plan is: raise the furnace body from room temperature to 120°C at a rate of 5°C / h, heat preservation for 60 hours; then raise the temperature to 280°C at a speed of 5°C / h, and maintain heat preservation for 60 hours; Raise the temperature to 600°C at a speed of 10°C / h, heat preservation and maintenance for 40 hours; raise the temperature to 800°C at a speed of 10°C / h, heat preservation and maintenance for 20 hours; then raise the temperat...

Embodiment 2

[0027] First, design the furnace body structure of the regenerative forging heating furnace, then design the corresponding furnace scheme according to the gas source of the manufacturer, prepare and repair the refractory white foam stone bricks according to the needs, and finally use white foam bricks according to the furnace structure diagram Foam stone bricks are used as the refractory layer of the furnace wall and roof to create a regenerative forging furnace. After the furnace is formed, it is baked according to the furnace plan. The oven program is as follows: raise the furnace body from room temperature to 110°C at a rate of 10°C / h, heat preservation and maintenance for 70 hours; Raise the temperature to 620°C at a speed of 15°C / h, heat preservation and maintenance for 40 hours; raise the temperature to 820°C at a speed of 15°C / h, and heat preservation and maintenance for 20 hours; then raise the temperature to 1200°C at a speed of 20°C / h, and heat preservation and maint...

Embodiment 3

[0029] First, design the furnace body structure of the regenerative forging heating furnace, then design the corresponding furnace scheme according to the gas source of the manufacturer, prepare and repair the refractory white foam stone bricks according to the needs, and finally use white foam bricks according to the furnace structure diagram Foam stone bricks are used as the refractory layer of the furnace wall and roof to create a regenerative forging furnace. After the furnace is formed, it is baked according to the furnace plan. The oven plan is: raise the furnace body from room temperature to 130°C at a rate of 5°C / h, heat preservation and maintenance for 80 hours; The temperature is raised to 630°C at a speed of h, and the heat preservation is maintained for 45 hours; the temperature is raised to 830°C at a speed of 10°C / h, and the heat preservation is maintained for 20 hours;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com