Natural fiber composite board, and manufacturing method and application thereof

A technology of natural fibers and composite materials, applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve the problems of difficult dispersion of natural fibers, poor impregnation effect of natural fibers and resins, etc. The effect of ensuring performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

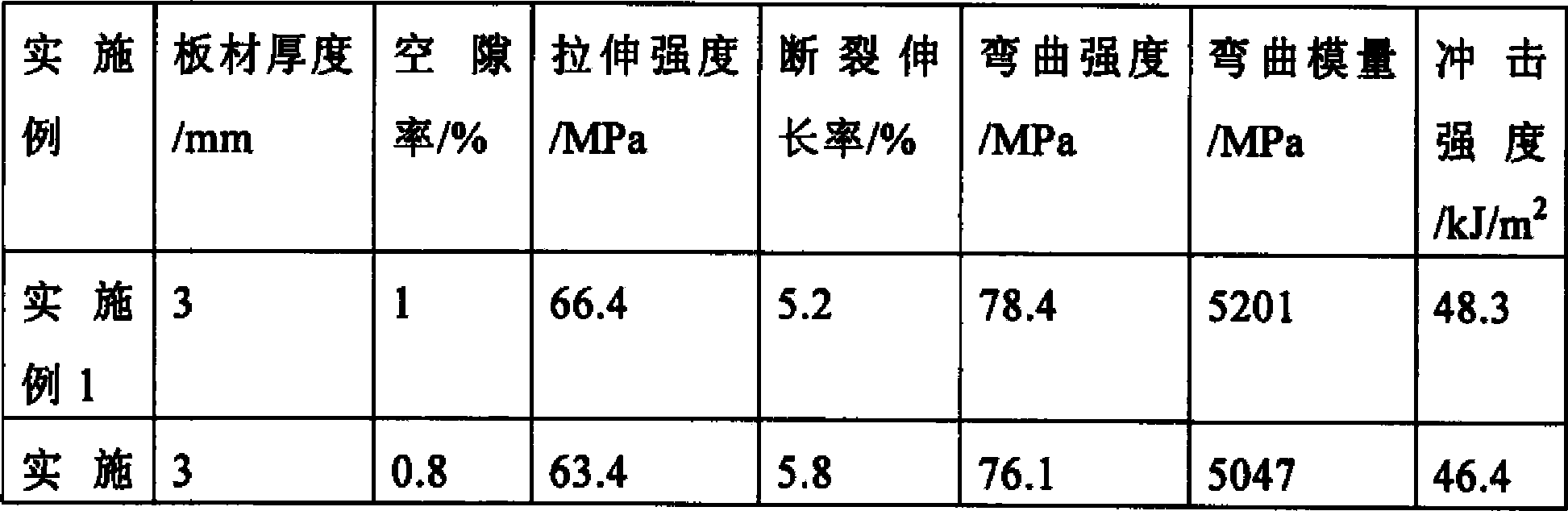

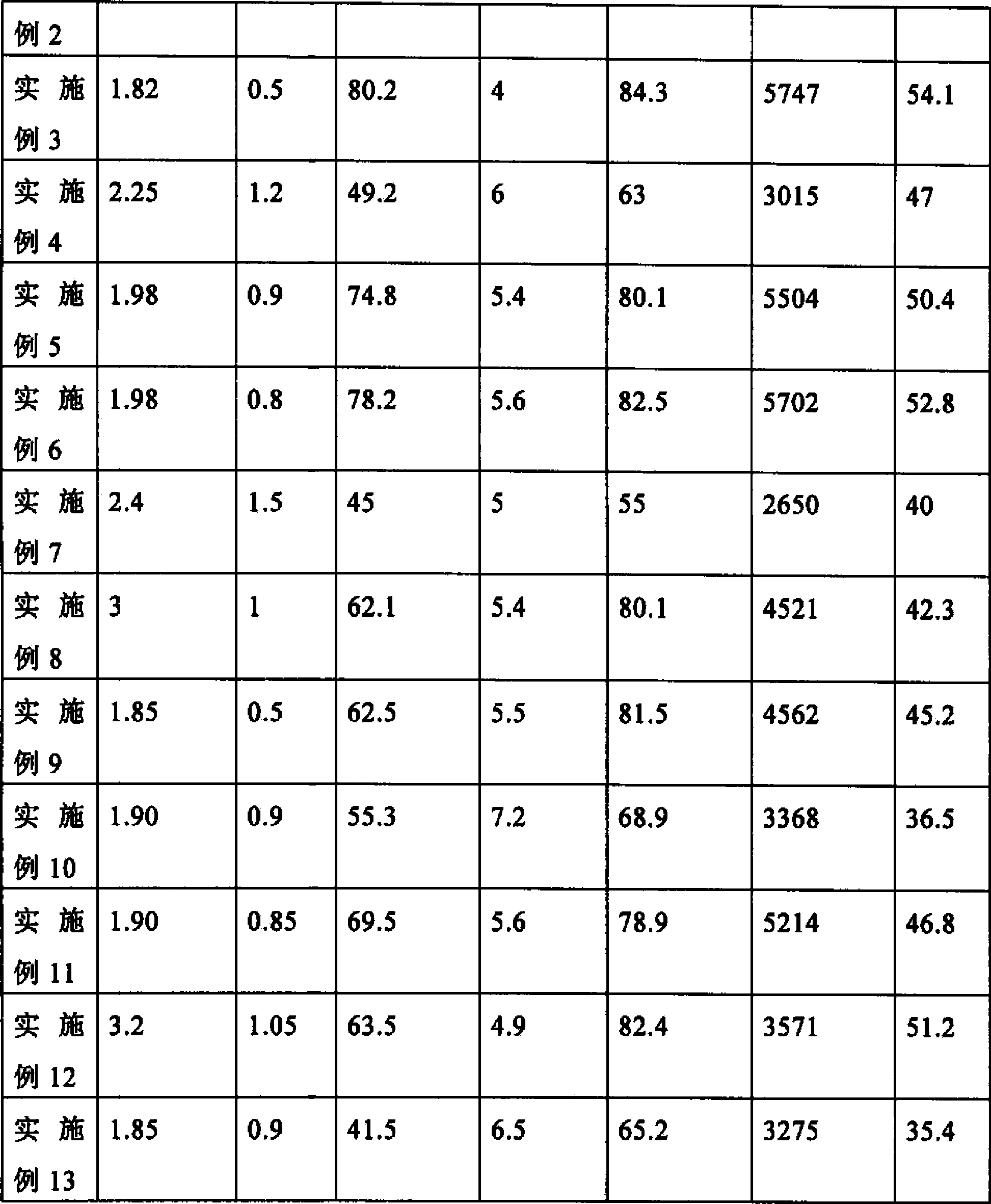

Embodiment 1

[0046] (1) Get maleic anhydride grafted polypropylene 2.5%, get polypropylene 48.5%, after mixing uniformly, prepare 1.5 deniers, the chopped fiber material that length is 38mm, this kind chopped fiber is processed, forms strip.

[0047] (2) get 48.5% hemp strip material and the chopped fiber strip material prepared after mixing the above-mentioned maleic anhydride graft and thermoplastic resin to draw, prepare and form roving, and carry out spinning process with roving, A mixed yarn with a fineness of 2 metric counts is prepared.

[0048] (3) Sizing the prepared blended yarn once.

[0049] (4) The yarn formed by sizing is processed into a plain weave fabric by a loom.

[0050] (5) Desizing the fabric once.

[0051] (6) Spray the fabric with vinyltrimethoxysilane to form a fabric treated with a coupling agent, and the content of the coupling agent used is 0.5% of the total weight ratio.

[0052](7) Take six layers of fabrics for lamination, and the lamination direction is 0...

Embodiment 2

[0054] (1) Take 50% polypropylene to prepare chopped fiber material with 3 deniers and a length of 76 mm, and process the chopped fiber to form strips.

[0055] (2) Get 50% flax strip material and above-mentioned chopped fiber strip material and carry out drawing, prepare and form roving, carry out spinning process with roving, prepare and form the mixed yarn that fineness is 1.5 metric counts.

[0056] (3) Sizing the prepared blended yarn once.

[0057] (4) The yarn formed by sizing is processed into a plain weave fabric by a loom.

[0058] (5) Desizing the fabric once.

[0059] (6) Take six layers of fabrics for lamination, and the lamination direction is 0 degree direction. The laminated fabrics are hot-pressed at a temperature of 190° C. and a molding pressure of 8 MPa to form a natural fiber reinforced thermoplastic resin sheet. The material properties are shown in Table 1.

Embodiment 3

[0061] (1) Take 45% polylactic acid, prepare 1 denier, chopped fiber material with a length of 76 mm, and process the chopped fiber to form strips.

[0062] (2) Get 55% ramie strip material and chopped fiber strip material and carry out drawing, prepare and form roving, carry out spinning process with roving, prepare and form the mixed yarn that fineness is 36 public counts.

[0063] (3) The yarn is processed into a twill fabric by a loom.

[0064] (4) Take 21 layers of fabrics and lay them up. The laying directions are 0 / 90 degrees and placed separately. The laminated fabrics are hot-pressed at a temperature of 185°C and a molding pressure of 4MPa to form a natural fiber reinforced thermoplastic resin. sheet. The material properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com