A kind of degradable composite material prepreg and its preparation method and device

A composite material and prepreg technology, applied in textiles and papermaking, physical treatment, fiber treatment, etc., can solve the problems of unsuitable production of natural fiber reinforced PLA, inability to form reinforced prepreg tape, and degradation of PLA mechanical properties, and achieve Good self-extinguishing property, less environmental hazards, and the effect of ensuring safety and environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

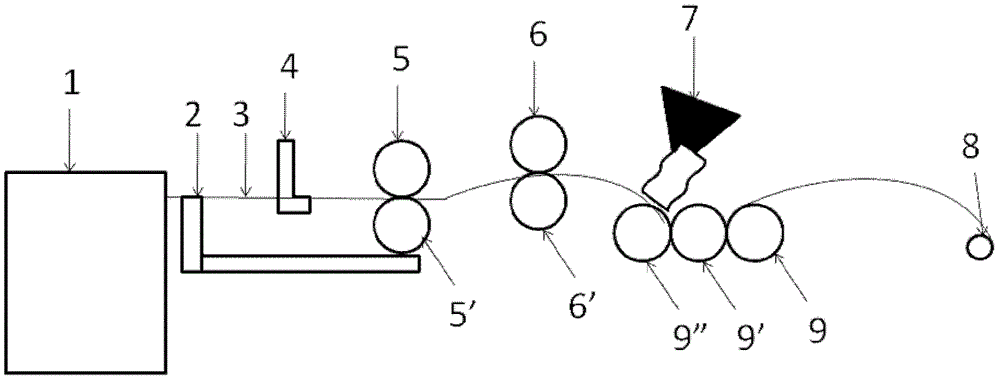

Method used

Image

Examples

Embodiment 1

[0056] A kind of preparation method of degradable composite material prepreg, this preparation method comprises the following steps:

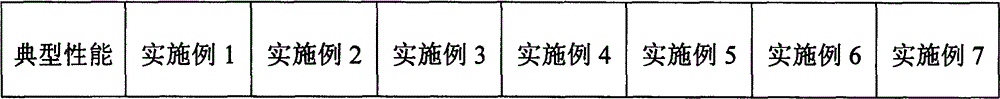

[0057] 70 parts of PLA resin, 5 parts of dilauryl thiodipropionate, 10 parts of polyhydroxyalkanoate, 3 parts of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate Parts, 5 parts of polyethylene glycol, 5 parts of zinc borate, 1 part of isooctyl 3-mercaptopropionate, 1 part of 4,4-dimethyl-2,4-diphenyl-1-butene in the mixer Mixed in medium for 7 minutes, fully mixed and then added to a twin-screw extruder to extrude and pelletize. The screw speed is 80r / min, and the extrusion temperature is 205°C to obtain a modified PLA resin; the performance test results are shown in Table 1.

[0058] With 120 rolls of jute fiber after plasma treatment, untwisting through untwisting machine, the form of loose expansion occurs, and the jute fiber after untwisting is processed through each step in embodiment 1, wherein in the coating extruder The extruded resin i...

Embodiment 2

[0060] A kind of preparation method of degradable composite material prepreg, this preparation method comprises the following steps:

[0061] Take 82 parts of PLA resin, 4 parts of phenylene diisodecyl phosphite, 7 parts of polyethylene glycol, 2 parts of 2-(2'-hydroxy-5'-)benzotriazole, 2 parts of aluminum hydroxide, 3 parts of magnesium were mixed in a mixer for 4 minutes, then added to a twin-screw extruder after mixing, extruded and granulated, the screw speed was 75r / min, and the extruder head temperature was 190°C.

[0062] 80 volumes of flax fibers after plasma treatment are untwisted by an untwisting machine, and a loose and expanded form appears, and the flax fibers after untwisting are processed through the steps in Example 1, wherein in the coating extruder The extruded resin is the above-mentioned modified PLA resin, and its extrusion temperature is 210°C. The natural fiber and PLA are impregnated on both sides, cooled, and rolled up to prepare a fully degradable ...

Embodiment 3

[0064] A kind of preparation method of degradable composite material prepreg, this preparation method comprises the following steps:

[0065] Get 85 parts of PLA resin, 1 part of dilauryl thiodipropionate, 2 parts of polyhydroxyalkanoate (PHA), 1 part of 2,4-dihydroxy-benzophenone, 2 parts of decabromodiphenylethane, 3 parts of hexabromocyclododecane, 5 parts of silicone oil, 1 part of 4-diphenyl-4-methyl-1-pentene, mixed in the raw material mixer for 6 minutes, mixed and added to the twin-screw extruder , extrusion granulation, the screw speed is 75r / min, and the extruder head temperature is 190°C. In the present embodiment, 150 rolls of jute fiber through alkali treatment are taken through the untwisting machine 1 to untwist, and the natural fiber 3 after untwisting, which is the jute fiber here, is placed on the natural fiber arrangement device 2 and passed through the natural fiber After the direction control 4, enter the natural fiber pressing roller 5, 5', then pass thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com