Micro-nano intragranular multiphase granule and thermal explosion reaction synthetic method thereof

A thermal explosion reaction, micro-nano technology, applied in the field of micro-nano composite materials and their synthesis, micro-nano intracrystalline multi-phase particles and their thermal explosion reaction synthesis method, can solve the problems of poor toughness, high brittleness, etc., and achieve improved performance , Improve toughness and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

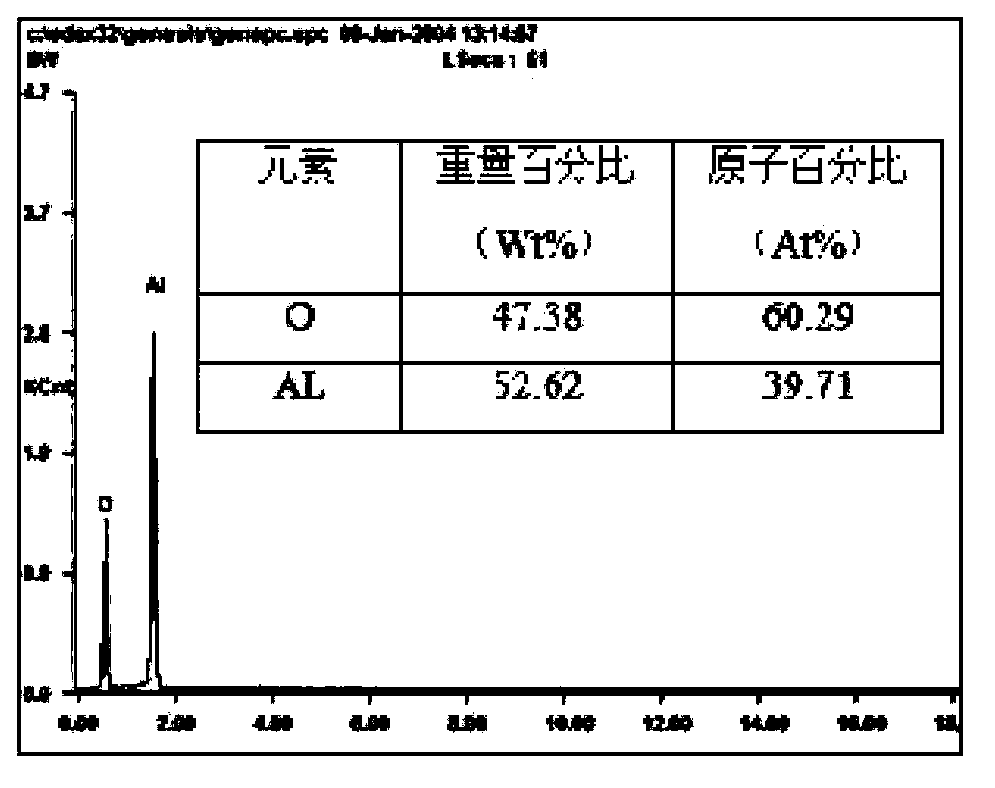

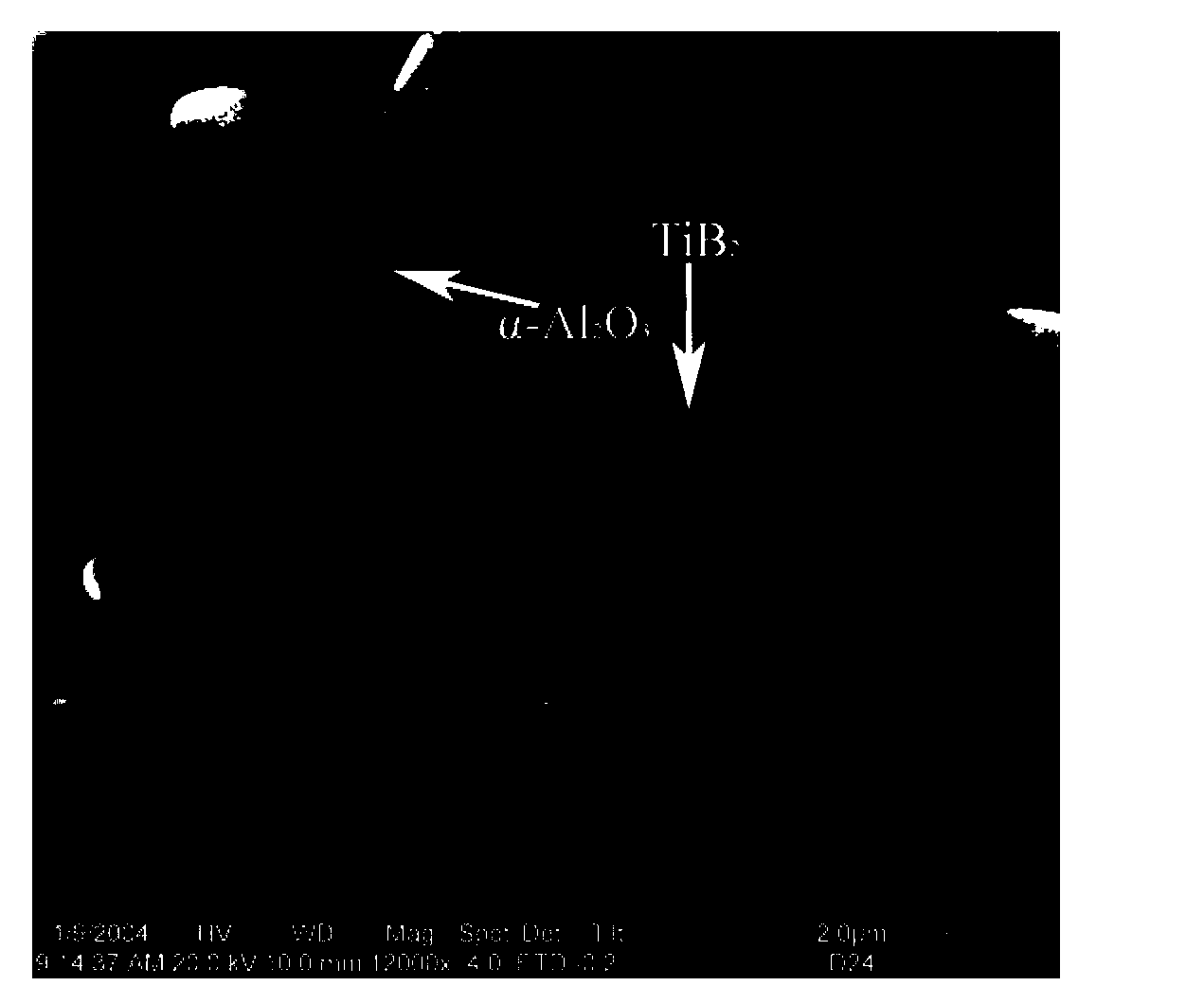

[0031] Example 1: Al-TiO 2 -B 2 o 3 reaction system

[0032] (1) Preparation of reaction samples Al powder, TiO 2 Powder and B 2 o 3 The molar ratio of the powder is 10:1:1, and then they are put into a ball mill tank, mixed with a ball-to-powder ratio of 5:1, and a speed of 300p.r.m, and then extruded into a billet with a pressure of 120MPa to make a compact. Sample;

[0033] (2) Loading and vacuuming the compacted sample into the vacuum reaction furnace, and vacuuming to 10 -4 -10 -3 Pa;

[0034] (3) Reaction synthesis Adjust the input power, the heating rate is 20K / min and the temperature rises to 900°C for the compacted sample to undergo a chemical reaction;

[0035] (4) Heat preservation Once the chemical reaction of the reaction sample occurs, the input power can be lowered, and the power input can be stopped after 30 minutes of heat preservation.

[0036] (5) Cool down and take out the furnace. When the furnace is cooled to room temperature, the furnace is o...

Embodiment 2

[0042] Example 2: Al-TiO 2 -B 2 o 3 reaction system

[0043] (1) Preparation of reaction samples Al powder, TiO 2 Powder and B 2 o 3 The molar ratio of the powder is 12:1:1, and then they are put into a ball mill tank, ball milled and mixed at a ball powder ratio of 4.5:1 at a speed of 280p.r.m, and then extruded into a billet with a pressure of 120MPa to make a compact. Sample;

[0044] (2) Loading and vacuuming the compacted sample into the vacuum reaction furnace, and vacuuming to 10 -4 -10 -3 Pa;

[0045] (3) Reaction synthesis Adjust the input power, raise the temperature at a heating rate of 18K / min, and the chemical reaction will occur in the compacted sample at 880°C;

[0046] (4) Heat preservation Once the chemical reaction of the reaction sample occurs, the input power can be lowered, and the power input can be stopped after 50 minutes of heat preservation.

[0047] (5) Cool down and take out the furnace. When the furnace is cooled to room temperature, th...

Embodiment 3

[0052] Example 3: Al-TiO 2 -B 2 o 3 reaction system

[0053] (1) Preparation of reaction samples Al powder, TiO 2 Powder and B 2 o 3 The molar ratio of the powder is 17:1:1, and then they are put into a ball mill tank, mixed with a ball powder ratio of 5:1, 300p.r.m speed of ball milling, and then extruded into a billet with a pressure of 120MPa to make a green compact. Sample;

[0054] (2) Loading and vacuuming the compacted sample into the vacuum reaction furnace, and vacuuming to 10 -4 -10 -3 Pa;

[0055] (3) Reaction synthesis Adjust the input power, heat up at a heating rate of 15K / min, and the compacted sample undergoes a chemical reaction at 860°C;

[0056] (4) Heat preservation Once the chemical reaction of the reaction sample occurs, the input power can be lowered, and the power input can be stopped after 60 minutes of heat preservation.

[0057] (5) Cool down and take out the furnace. When the furnace is cooled to room temperature, the furnace is opened f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com