Method of improving corrosion resistance of oil tube

A corrosion-resistant, oil-pipe technology, used in pipeline protection, overlay coating, pipeline anti-corrosion/rust protection, etc., can solve the problems of reduced mechanical properties, unattainable, high brittleness of oil pipes, etc., and achieves temperature resistance performance Good, high corrosion resistance, the effect of improving the corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

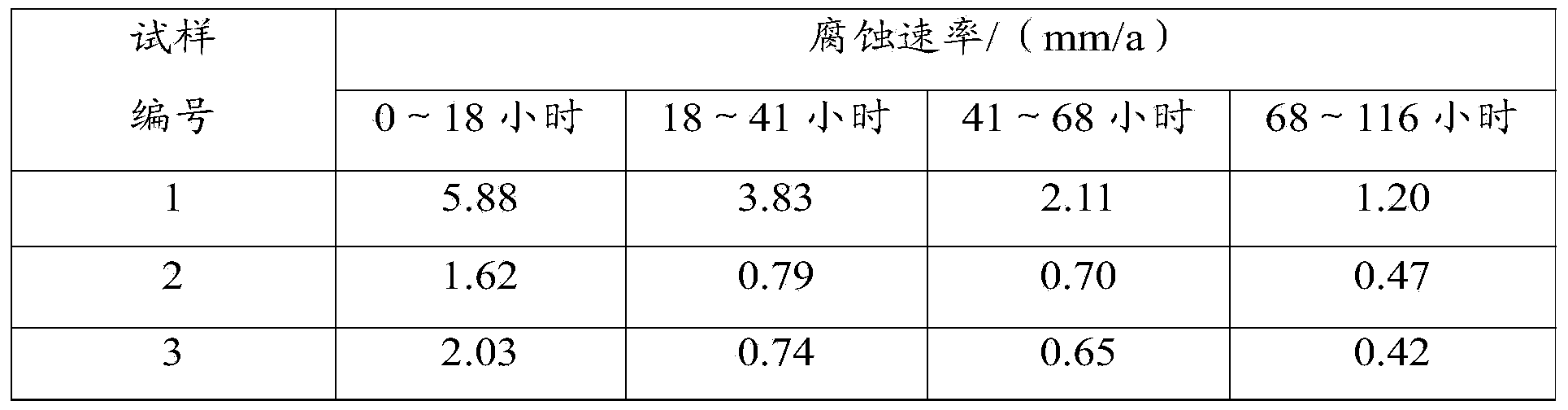

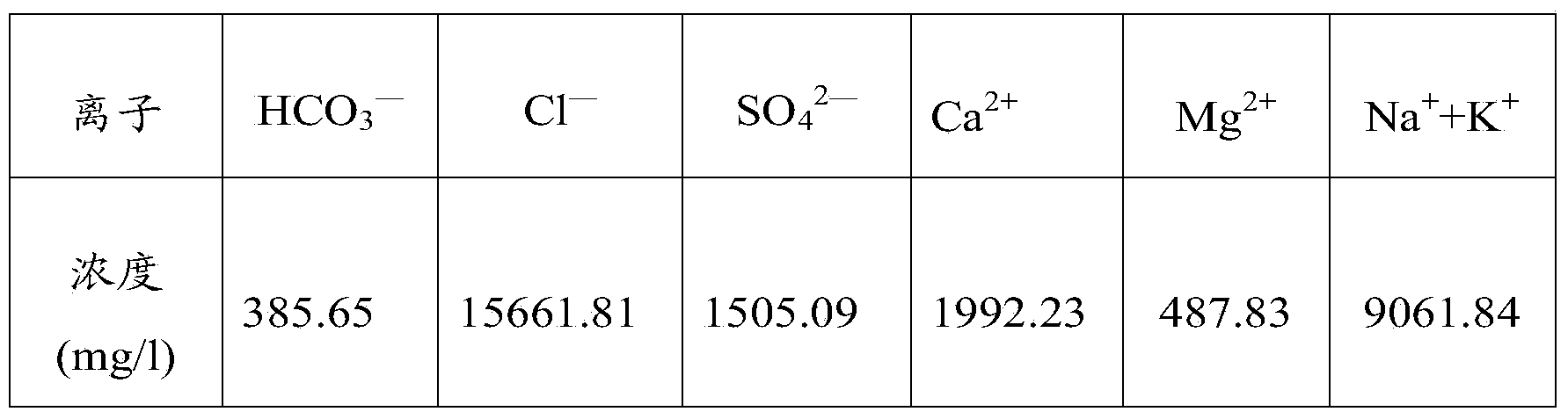

Embodiment 1

[0050] This embodiment provides a method for improving the corrosion resistance of oil pipelines, the method comprising the following steps:

[0051] 1) Pre-cleaning;

[0052] 2) Installing the card: install the oil pipeline into the tooling;

[0053] 3) Preheating: Preheat the X80 oil pipeline in an air heating furnace at a temperature of 375°C for 30 minutes;

[0054] 4) Nitride ion infiltration: the preheated oil pipeline enters the nitrogen carbon ion infiltration furnace, the temperature is 600 ° C, and the time is 75 minutes; the nitrogen carbon yttrium ion infiltration agent is composed of: Na 2 CO 3 11%, K 2 CO 3 15%, NaCl24%, CO(NH 2 ) 2 40%, K 2 SO 3 2%, CeCO 3 2%, LiOH5%, YCl 3 1%;

[0055] 5) Ion activation: The oil delivery pipe infiltrated by nitrogen carbon yttrium ions enters the ion activation furnace, the temperature is 500 ° C, and the time is 75 minutes; the ion activation penetration agent is composed of: Na 2 SO 4 7%, Na 2 CO 3 10%, K 2 CO...

Embodiment 2

[0062] This embodiment provides a method for improving the corrosion resistance of oil pipelines, the method comprising the following steps:

[0063] 1) Pre-cleaning;

[0064] 2) Installing the card: install the oil pipeline into the tooling;

[0065] 3) Preheating: Preheat the X80 oil pipeline in an air heating furnace at a temperature of 300°C for 40 minutes;

[0066] 4) Nitride ion infiltration: the preheated oil pipeline enters the nitrogen carbon ion infiltration furnace, the temperature is 550 ° C, and the time is 120 minutes; the nitrogen carbon yttrium ion infiltration agent is composed of: Na 2 CO 3 10%, K 2 CO 3 10%, NaCl23.97%, CO(NH 2 ) 2 40%, K 2 SO 3 3%, CeCO 3 3%, LiOH10%, YCl 3 0.03%;

[0067] 5) Ion activation: The oil delivery pipe infiltrated by nitrogen carbon yttrium ions enters the ion activation furnace at a temperature of 450°C for 120 minutes; the ion activation permeation agent is composed of: Na 2 SO 4 5%, Na 2 CO 3 12%, K 2 CO 3 12%...

Embodiment 3

[0074] This embodiment provides a method for improving the corrosion resistance of oil pipelines, the method comprising the following steps:

[0075] 1) Pre-cleaning;

[0076] 2) Installing the card: install the oil pipeline into the tooling;

[0077] 3) Preheating: Preheat the X80 oil pipeline in an air heating furnace at a temperature of 450°C for 20 minutes;

[0078] 4) Nitride ion infiltration: the preheated oil pipeline enters the nitrogen carbon ion infiltration furnace, the temperature is 660 ° C, and the time is 30 minutes; the nitrogen carbon yttrium ion infiltration agent is composed of: Na 2 CO 3 15%, K 2 CO 3 20%, NaCl25%, CO(NH 2 ) 2 31%, K 2 SO 3 2%, CeCO 3 1%, LiOH5%, YCl 3 1%;

[0079] 5) Ion activation: The oil delivery pipe infiltrated by nitrogen carbon yttrium ions enters the ion activation furnace at a temperature of 550°C for 120 minutes; the ion activation permeation agent is composed of: Na 2 SO 4 10%, Na 2 CO 3 10%, K 2 CO 3 10%, NaCl2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com