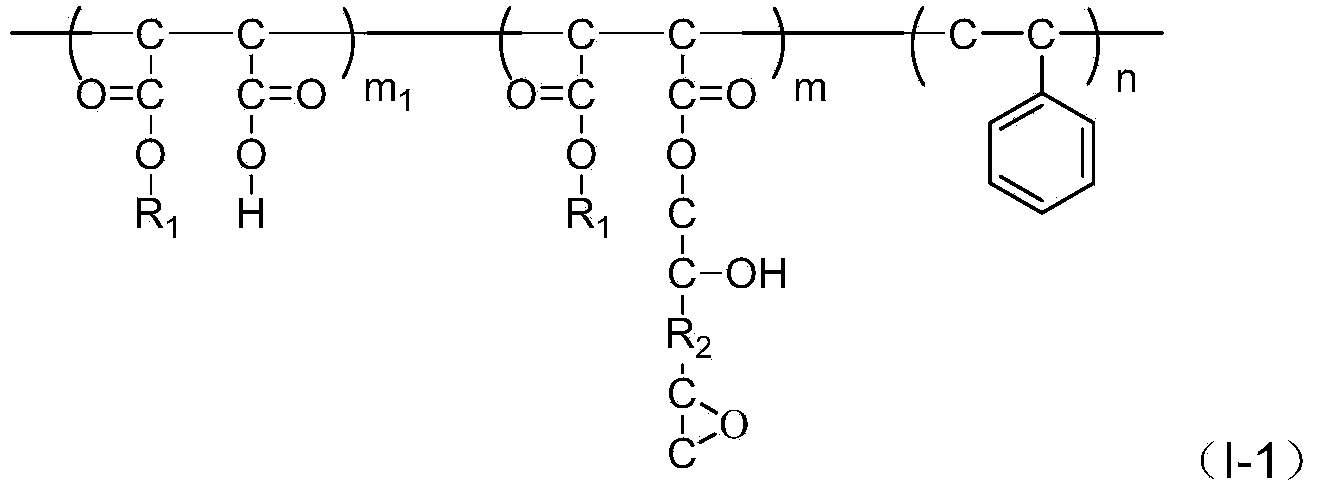

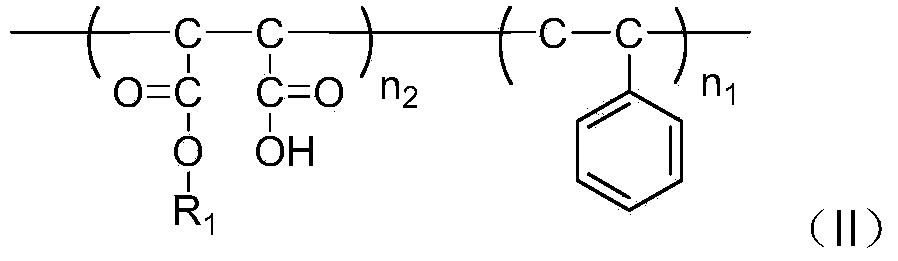

Epoxy modified maleic anhydride copolymer prepolymer, its resin composition, preparation method and application

A resin composition, maleic anhydride technology, applied in chemical instruments and methods, synthetic resin layered products, circuit substrate materials, etc., can solve the problem of low glass transition temperature, little contribution to heat resistance and electrical performance, Poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] 1) Preparation of maleic anhydride copolymer prepolymer solution:

[0073] With 100 parts by weight of solid styrene / maleic anhydride copolymer, add 130 parts by weight of methyl ethyl ketone solvent, dissolve into liquid styrene / maleic anhydride copolymer, add 27 parts by weight of benzyl alcohol and 0.635 parts by weight of 4 - tert-butyl-2,6-dimethyl-aniline, stirred and mixed at a temperature of 80° C. for 10 hours to obtain a solution.

[0074] 2) Preparation of epoxy-modified maleic anhydride copolymer prepolymer:

[0075] Mix 100 parts by weight of the maleic anhydride copolymer prepolymer solution in step 1) with 45.6 parts by weight of bisphenol A epoxy resin and 0.635 parts by weight of 4-tert-butyl-2,6-dimethyl-aniline , Stirring and mixing at a temperature of 80°C for 8 hours.

[0076] 3) Preparation of resin composition of epoxy-modified maleic anhydride copolymer prepolymer:

[0077] With 30 parts by weight of step 2) the epoxy-modified maleic anhydride...

Embodiment 2

[0081] 1) Preparation of maleic anhydride copolymer prepolymer solution:

[0082] The preparation method is as described in Example 1.

[0083] 2) Preparation of epoxy-modified maleic anhydride copolymer prepolymer:

[0084] With 30 parts by weight of the maleic anhydride copolymer prepolymer in step 1) and 45.6 parts by weight of dicyclopentadiene type epoxy resin and 0.635 parts by weight of 4-tert-butyl-2,6-dimethyl- Aniline was obtained by stirring and mixing at a temperature of 80°C for 10 hours.

[0085] 3) Preparation of resin composition of epoxy-modified maleic anhydride copolymer prepolymer:

[0086] With 30 parts by weight of epoxy-modified maleic anhydride copolymer prepolymer in step 2), 100 parts by weight of bisphenol A novolak epoxy resin, 30 parts by weight of phenolic resin, 0.1 parts by weight of 2-formaldehyde imidazole, 100 parts by weight of fused silica, 20 parts by weight of flame retardant and 30 parts by weight of propylene glycol methyl ether were m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com