Plastic refractory and use thereof

A plastic and refractory technology, applied in the field of refractory materials, can solve the problems of easy melting, cracking and poor thermal conductivity of refractory materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

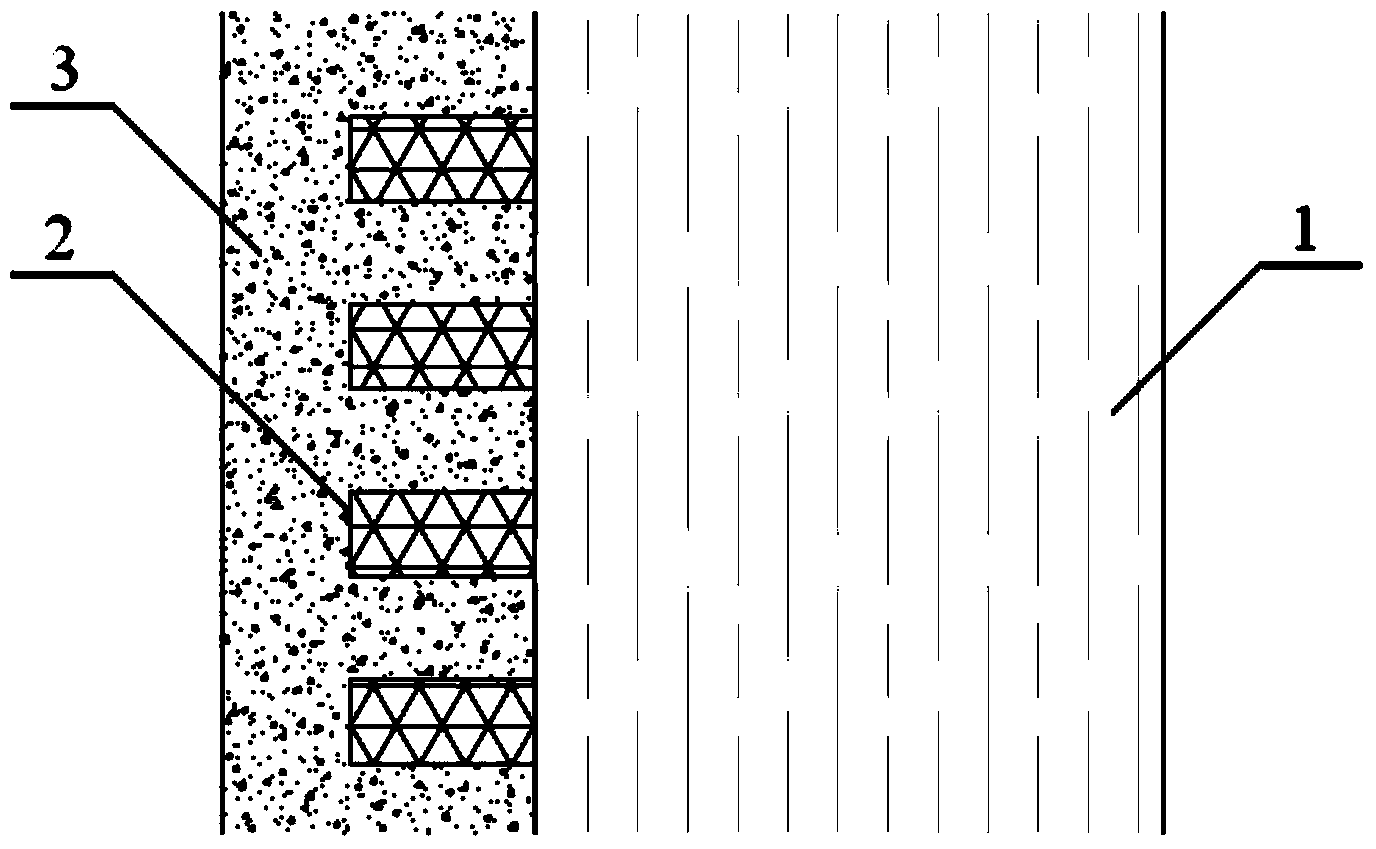

Image

Examples

Embodiment 1

[0042] Comparison of physical and chemical indicators between the refractory plastic (1#) of the present invention and the corundum ramming material (2#) of Henan Dengfeng Konore Ceramic Material Co., Ltd.

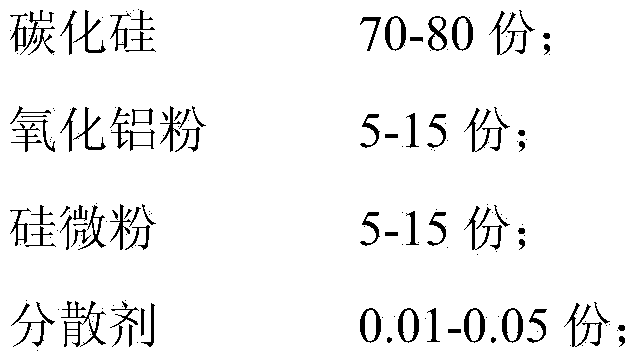

[0043] The formula of refractory plastic (1#) of the present invention is as follows (see table 1):

[0044] Raw material type

Particle size (YB / T5204 and YB / T5164)

parts by weight

SiC97%

3-1

10

SiC97%

1-0

35.5

SiC97%

-0.21

2

SiC97%

-200M

5

SiC_97%

-325M

20.5

Silica powder 96%

8

Alumina powder

-800M

10

MgO)

0.05

sodium tripolyphosphate

0.15

Silica sol

7

[0045] Table 1

[0046] The preparation method of refractory plastic (1#) of the present invention is as follows:

[0047] 1) After mixing the raw materials except the binder and aggregate SiC according to the ratio of the raw materials, put...

Embodiment 2

[0056] table 3

[0057] Prepare refractory plastic material according to the formula of table 3, method is as follows:

[0058] 1) After mixing the raw materials except the binder and aggregate SiC according to the ratio of the raw materials, put them into the mixer and mix them for three minutes;

[0059] 2) Put the SiC aggregate into the mixer and knead fully for three minutes, then store the kneaded material in bags (usually 25kg a bag);

[0060] 3) After being transported to the site of use, put the mixed material into the mixer, add the binder according to the proportion, and fully mix it for three minutes before it can be used as a refractory plastic.

[0061]The chemical indicators, bulk density, linear change rate, flexural strength, compressive strength, thermal conductivity and other parameters of the obtained refractory plastic material were measured and compared, and the performance of each parameter was similar to that of Example 1.

Embodiment 3

[0064] Table 4

[0065] Prepare refractory plastic material by the formula of table 4, method is as follows:

[0066] 1) After mixing the raw materials except the binder and aggregate SiC according to the ratio of the raw materials, put them into the mixer and mix them for three minutes;

[0067] 2) Put the SiC aggregate into the mixer and knead fully for three minutes, then store the kneaded material in bags (usually 25kg a bag);

[0068] 3) After being transported to the site of use, put the mixed material into the mixer, add the binder according to the proportion, and fully mix it for three minutes before it can be used as a refractory plastic.

[0069] The chemical indicators, bulk density, linear change rate, flexural strength, compressive strength, thermal conductivity and other parameters of the obtained refractory plastic material were measured and compared, and the performance of each parameter was similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com