Fuel cell fast heating system and method adopting cold starting

A fuel cell and rapid heating technology, used in fuel cells, fuel cell additives, circuits, etc., can solve the problems of high plate processing requirements, low heating efficiency, and excessive energy in the device, so as to improve the thermal assist efficiency, heating High efficiency and short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

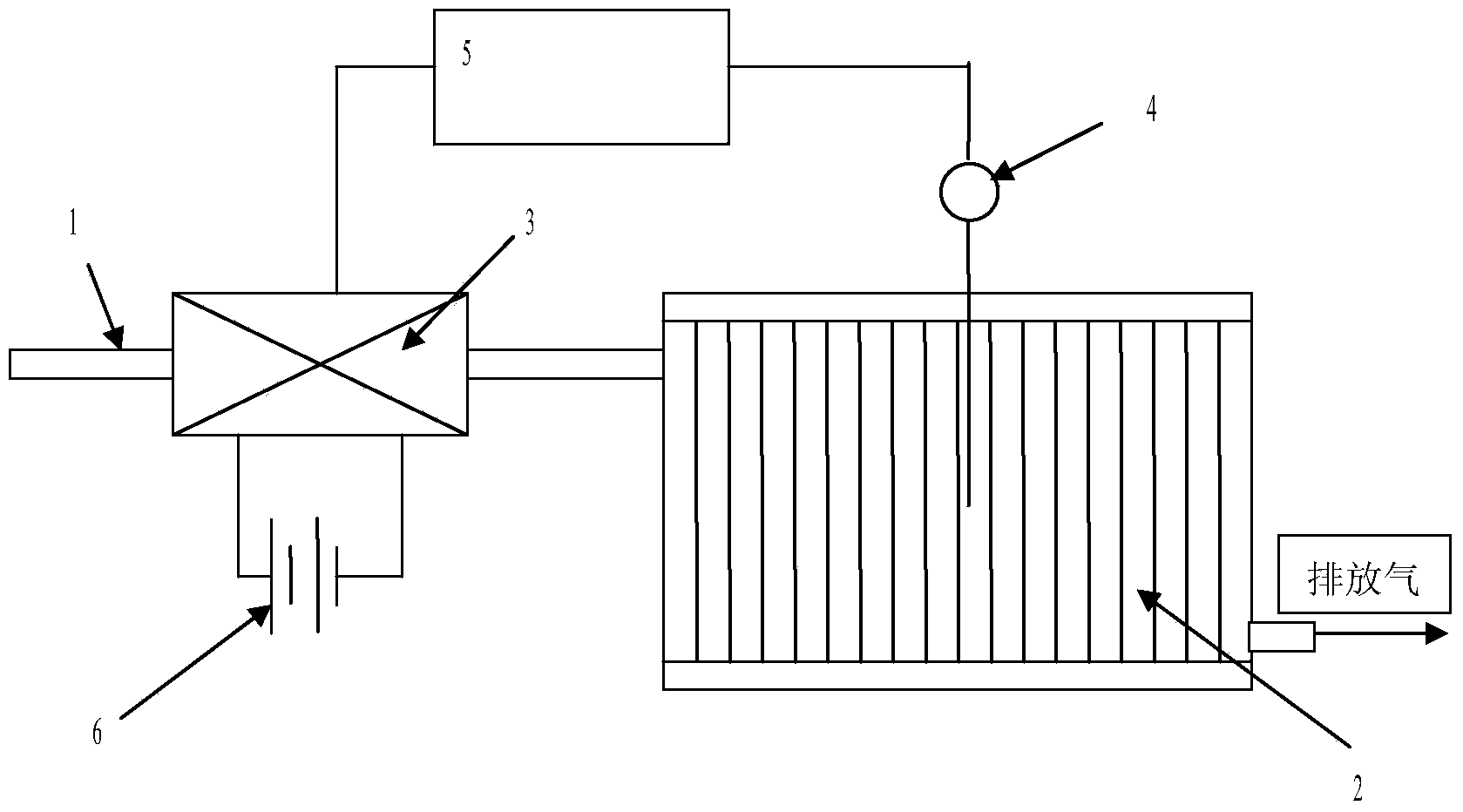

[0021] Example 1: The fuel cell cold start rapid heating system of the present invention includes a hydrogen delivery pipeline 1 and a fuel cell stack 2, the hydrogen delivery pipeline 1 transports hydrogen to the flow channel on the anode side of the fuel cell stack, and the system also includes a heater 3 and a thermometer 4 and a battery control system 5; the heater 3 is arranged on the hydrogen delivery pipeline 1 to heat the hydrogen; the thermometer 4 is arranged inside the fuel cell stack 2 to measure the temperature of the stack; the battery control The data acquisition terminal of the system 5 is connected to the thermometer 4, and the output terminal is connected to the heater 3, and the heater 3 is controlled to be turned on and off according to the temperature inside the stack measured by the thermometer 4. The heater 3 is an electric heater, and the electric energy is converted into heat energy by the energy storage battery 6 to heat the hydrogen. The battery co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com