Cyclone Pulverized Coal Gasifier

A technology of gasification furnace and pulverized coal, which is applied in the gasification of granular/powdered fuel, manufacture of combustible gas, petroleum industry, etc., can solve the problem of high carbon residue, achieve the purpose of promoting reaction, speeding up reaction speed and reducing energy waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

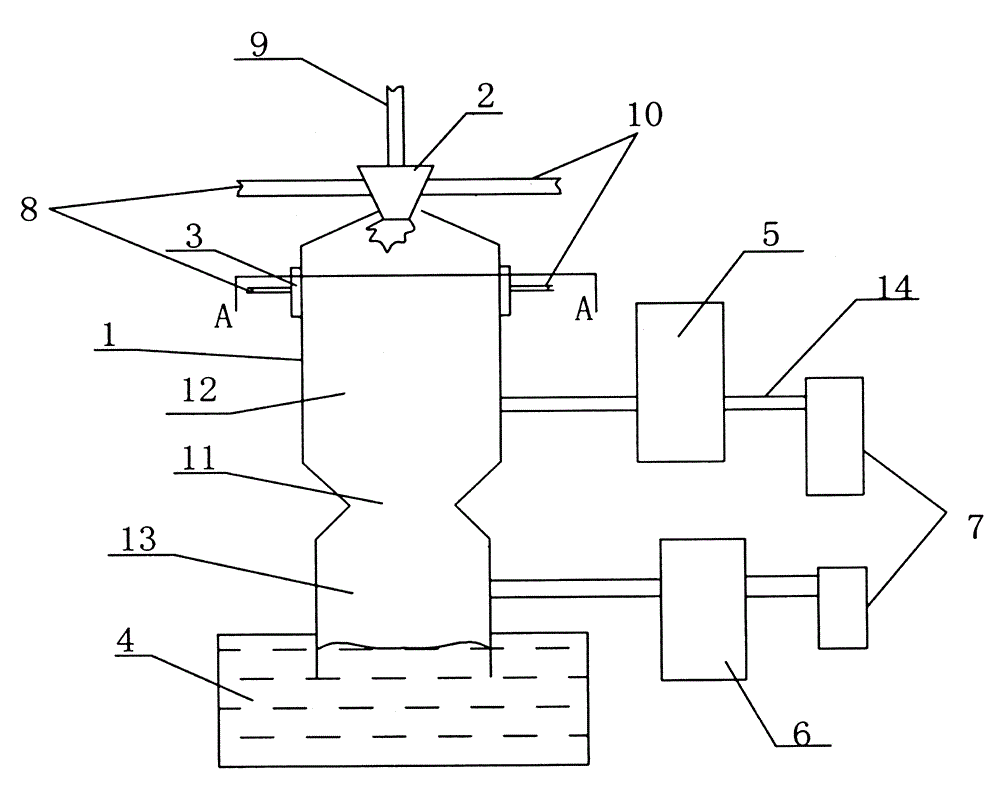

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

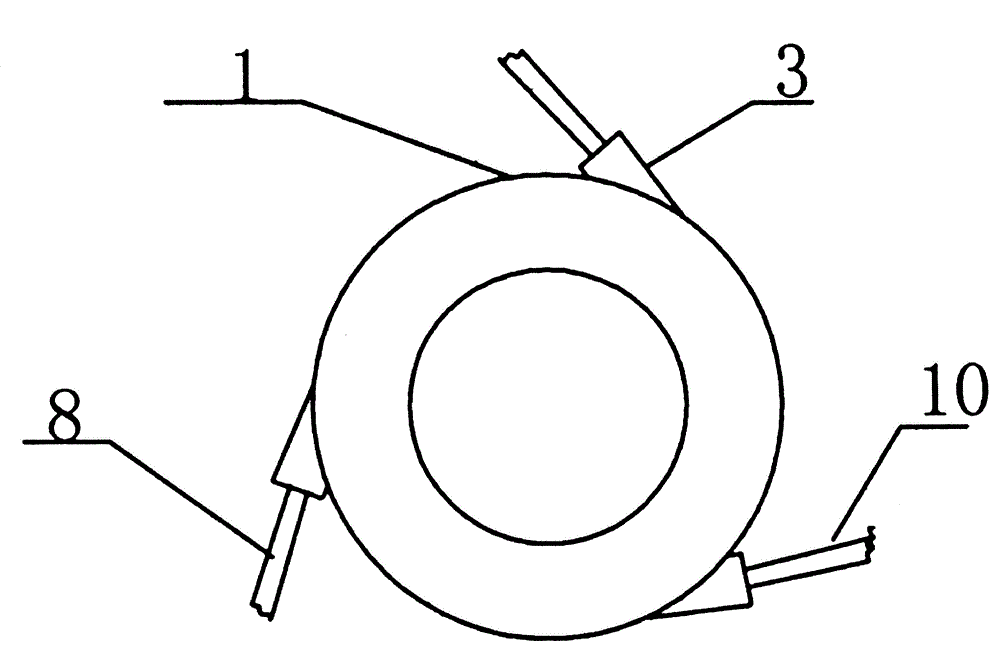

[0019] like Figure 1-Figure 2 As shown in the structure schematic diagram of the present invention, the top nozzle 2 is installed on the top of the body of furnace 1, the top nozzle 2 is connected with the oxygen pipeline 8, the pulverized coal pipeline 9 and the steam pipeline 10 respectively, and the furnace wall nozzle 3 is installed on the upper part of the furnace body 1. On the wall, the furnace wall of the present invention adopts a water-cooled wall, which can cool the furnace wall and prevent the furnace wall from being damaged by high temperature. Refractory materials are hung on the inner side of the water wall, and the slag is bonded to the furnace wall during operation to form a new furnace wall protection layer. The furnace body 1 is cylindrical, and the furnace wall nozzle 3 ring is arranged on the furnace wall of the furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com